Pipe-expansion tip cone and pipe-expansion method of the same

A technology of pipe expansion and top cone, applied in the field of pipe expansion top cone, can solve the problems of surface wrinkles of pipe fittings, increase production cost, reduce the service life of pipe expansion top cone, etc. The effect of a single deformation amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

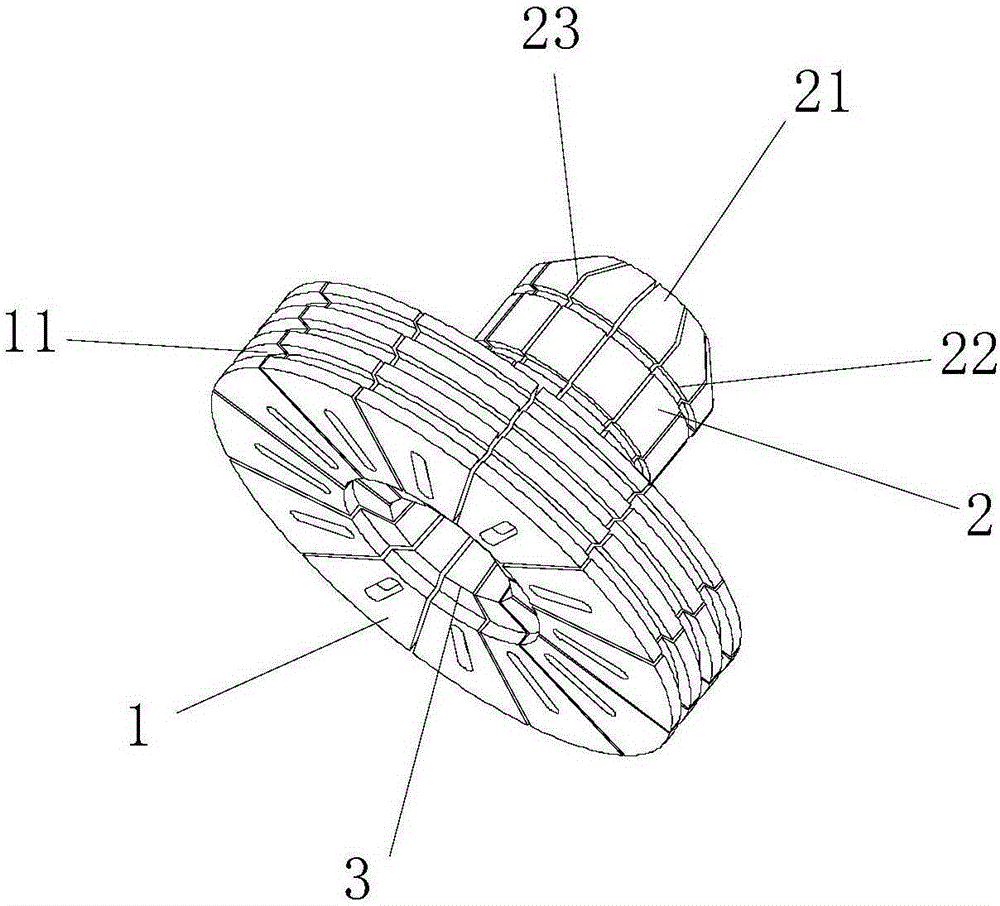

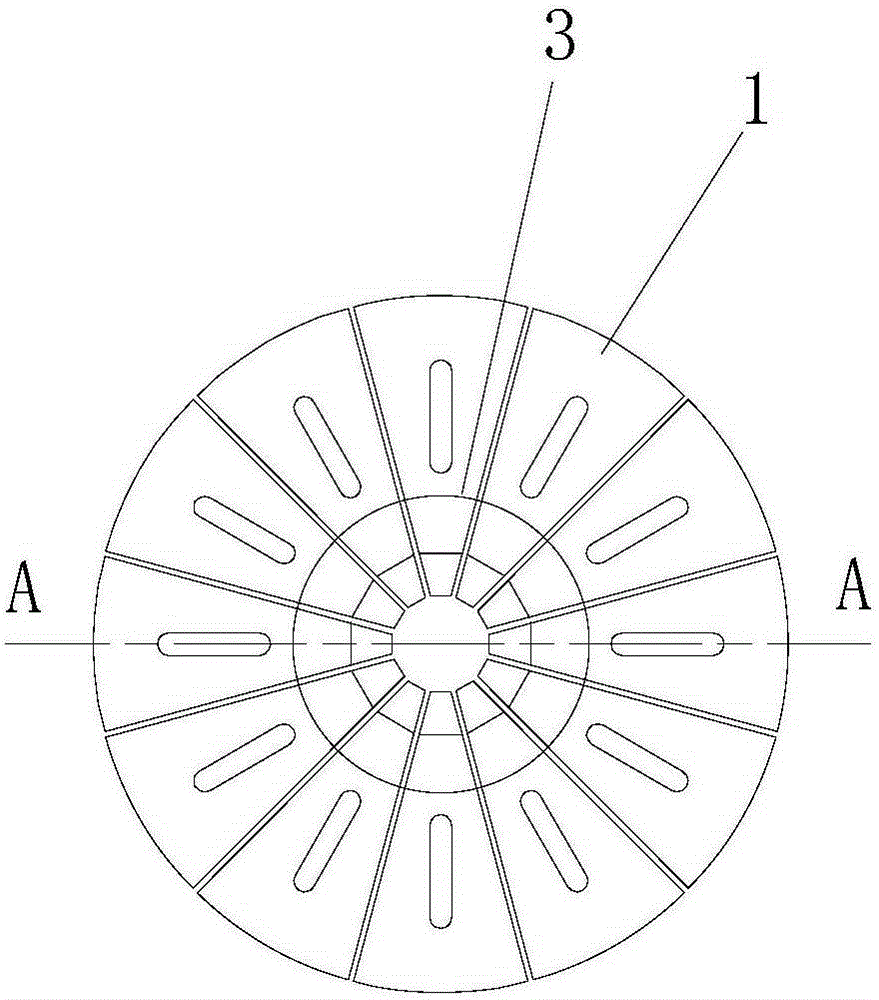

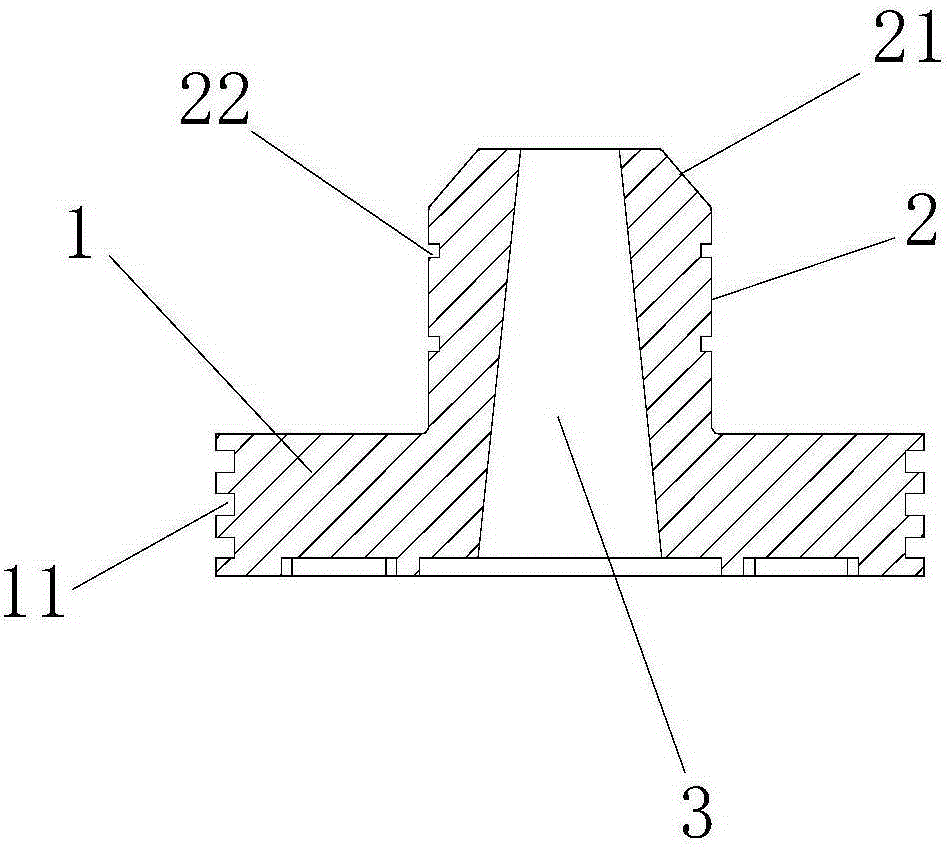

[0024] Example 1 Figure 1 to 3 As shown, the top cone of the expansion tube of this embodiment includes 12 L-shaped expansion tube monomers, each expansion tube monomer includes a fan-shaped portion 1 and a fan-shaped column portion 2, and the inner side of the fan-shaped column portion 2 is a conical arc The outer surface is a cylindrical arc surface, and 12 expander units are joined together in a centrally symmetrical manner to form the top cone of the expander; the fan-shaped part 1 of each expander unit constitutes an annular cover plate, and each expander unit is fan-shaped The inner surface of the cylinder part 2 cooperates to form a tapered hole 3, and its outer surface cooperates to form a deformed part. The outer tapered tube expansion shaft is inserted into the tapered hole 3, and the tapered hole 3 is inserted into the expansion tube shaft. , The top and the sector of the single fan-shaped column part 2 of the expanding tube swing around the elastic contraction ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com