A kind of preparation method of high moisture permeability polytetrafluoroethylene film

A polytetrafluoroethylene and moisture-permeable technology is applied in the field of preparation of high moisture-permeable polytetrafluoroethylene films, which can solve the problems of poor moisture permeability and poor uniformity of PTFE films, achieve good stability and improve the effects of stuffy heat problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

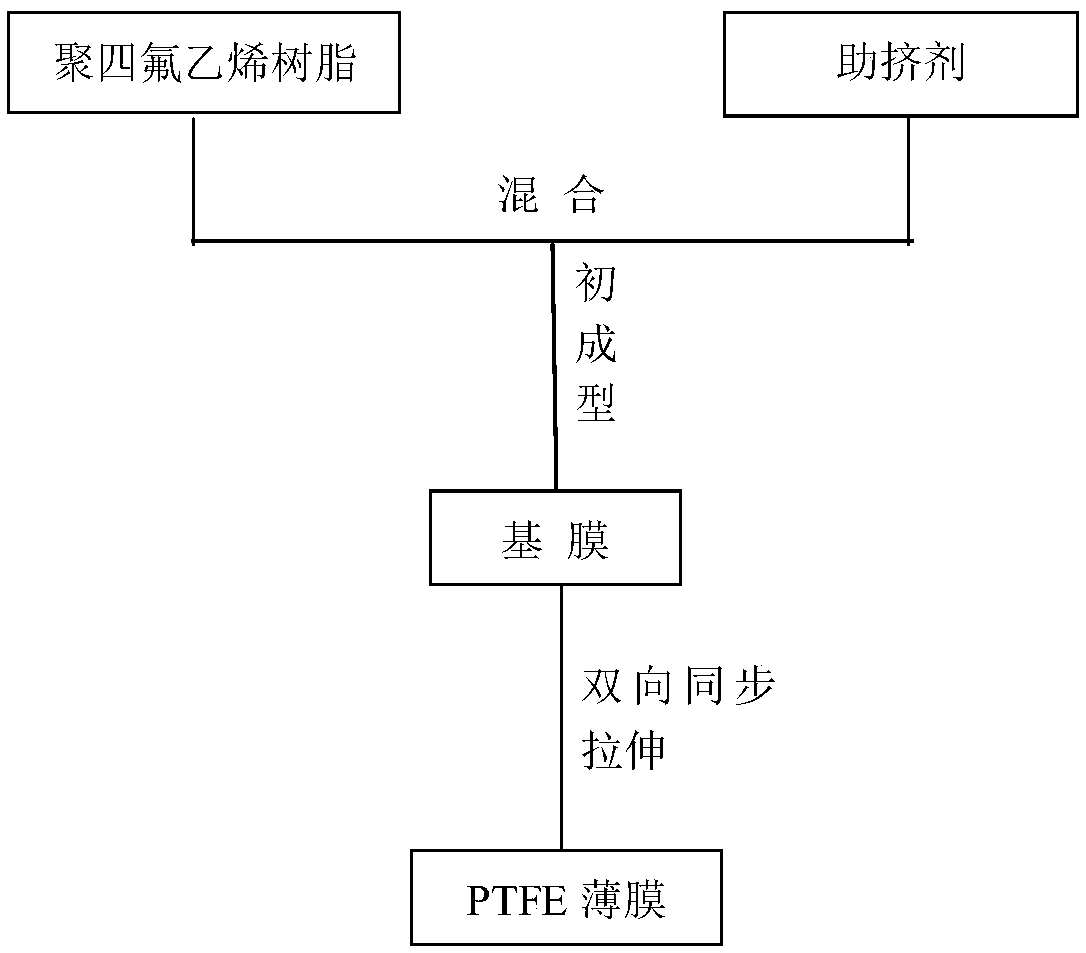

[0035] The preparation method of high moisture-permeable polytetrafluoroethylene film comprises the following steps connected in sequence:

[0036] (1) Mixing: mix polytetrafluoroethylene resin and extrusion aid in a ratio of 100:15 on a ball mill, the ball milling speed is 20r / min, and the mixing time is 20min;

[0037] (2) Primary molding: put the raw materials uniformly mixed in the previous process into the aging box, fully infiltrate at 45°C for 18 hours, and enter the equipment used for primary molding. The equipment used for primary molding includes sequential connection from top to bottom The blanking machine, push rod, film extruder, storage rack and pressure roller, the blanking machine includes two oil cylinders arranged up and down, and the feeding port is provided on the blanking machine; the storage rack includes a fixed frame and a fixed frame. More than two horizontal rods parallel to each other, all horizontal rods are parallel to the horizontal plane; there a...

Embodiment 2

[0046] The preparation method of high moisture-permeable polytetrafluoroethylene film comprises the following steps connected in sequence:

[0047] (1) Mixing: mix polytetrafluoroethylene resin and extrusion aid in a ratio of 100:20 on a ball mill, the ball milling speed is 30r / min, and the mixing time is 15min;

[0048] (2) Primary molding: Put the raw materials uniformly mixed in the previous process into the aging box, fully soak for 20 hours at a temperature of 45°C, and enter the equipment used for primary molding. The equipment used for primary molding includes sequential connection from top to bottom The blanking machine, push rod, film extruder, storage rack and pressure roller, the blanking machine includes two oil cylinders arranged up and down, and the feeding port is provided on the blanking machine; the storage rack includes a fixed frame and a fixed frame. More than two horizontal rods parallel to each other, all horizontal rods are parallel to the horizontal pla...

Embodiment 3

[0057] The preparation method of high moisture-permeable polytetrafluoroethylene film comprises the following steps connected in sequence:

[0058] (1) Mixing: mix polytetrafluoroethylene resin and extrusion aid in a ratio of 100:30 on a ball mill, the ball milling speed is 20r / min, and the mixing time is 20min;

[0059] (2) Primary molding: Put the raw materials uniformly mixed in the previous process into the aging box, fully infiltrate at 45°C for 22 hours, and enter the equipment used for primary molding. The equipment used for primary molding includes sequential connection from top to bottom The blanking machine, push rod, film extruder, storage rack and pressure roller, the blanking machine includes two oil cylinders arranged up and down, and the feeding port is provided on the blanking machine; the storage rack includes a fixed frame and a fixed frame. More than two horizontal rods parallel to each other, all horizontal rods are parallel to the horizontal plane; there a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com