Multistation belt conveyor head retractor device

A telescopic device and belt conveyor technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of small range of activities, inability to meet on-site operations, unstable telescopic structure of telescopic belt conveyors, etc., to increase the range of activities, save financial resources, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

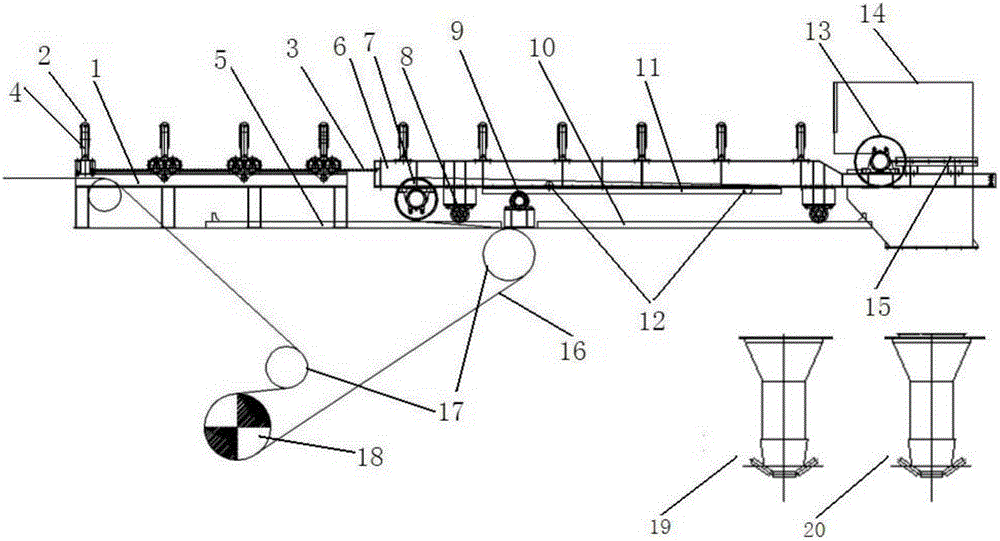

[0015] The telescopic device of the head of the multi-station belt conveyor can be made into two-position cross, three-position cross, or even more position cross according to the application requirements, such as figure 1 Shown, it is two intersections: be the first station 19, the second station 20. The walking mode of the device is a rack drive track walking mode, but is not limited thereto, and can also walk through a chain drive track. The overall layout of the device can be divided into two types: high bracket type and floor type: high bracket arrangement, that is, the telescopic head is supported by the high bracket above the cross-transposed tape machine, and the two are arranged in one space; floor type layout, That is, the telescopic head is arranged on the top floor of the cross-transposed tape machine, and the two are arranged in two spaces.

[0016] This embodiment is a floor-standing arrangement, including a sub-beam 1 fixed on the bottom transverse steel plate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com