A belt guide roller on a photovoltaic welding strip production equipment

A technology for production equipment and photovoltaic ribbon, applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of single structure and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

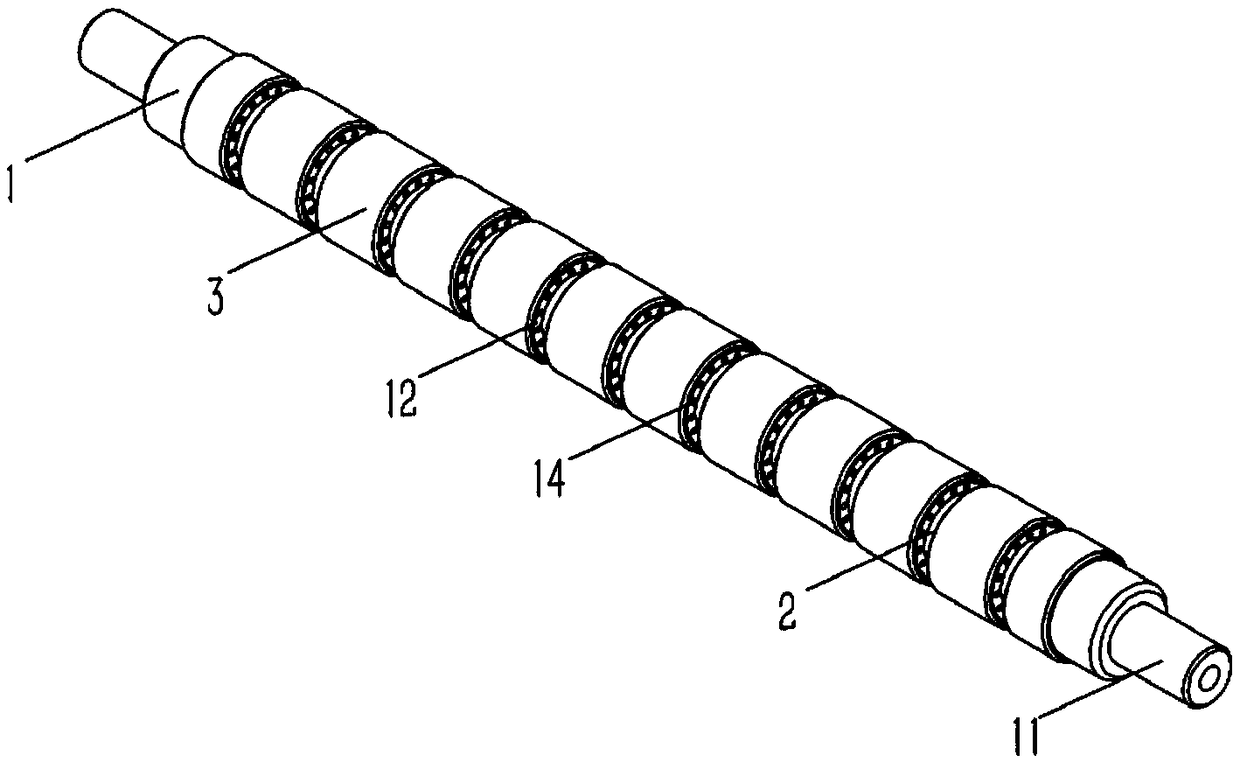

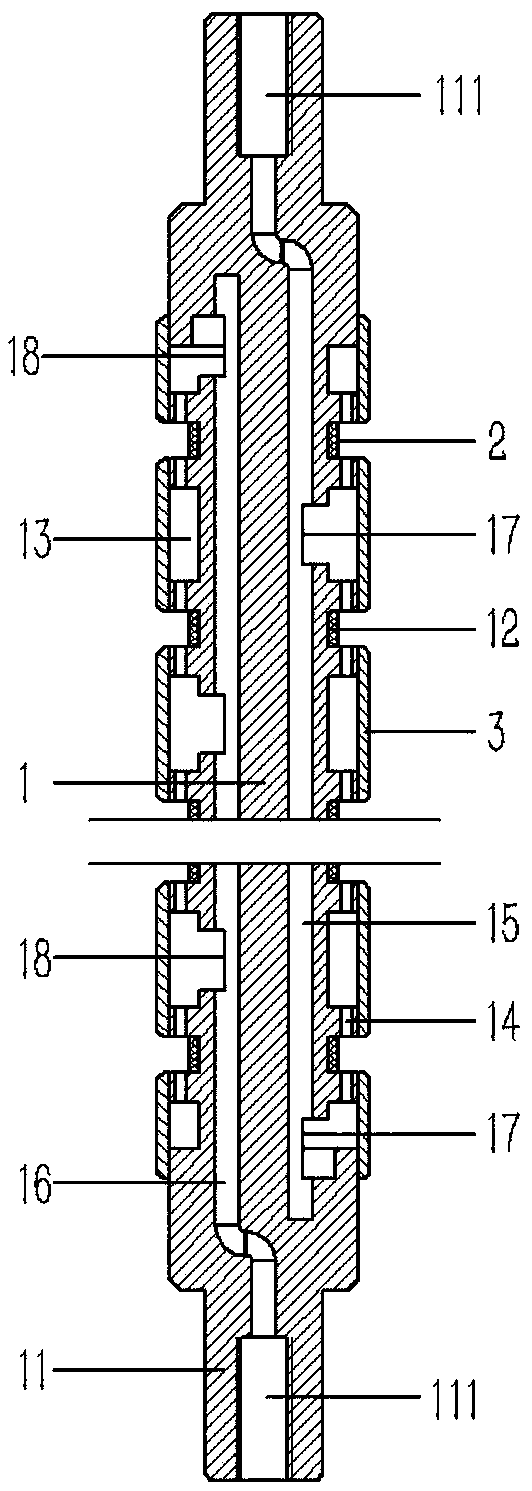

[0015] Example: see figure 1 , 2 As shown, a tape guide roller on a photovoltaic ribbon production equipment includes a roller shaft 1, pillars 11 are formed at both ends of the roller shaft 1, and several annular belt guide grooves 12 are formed on the roller shaft 1, and the roller shaft 1 An annular ventilation groove 13 is formed on the roller shaft 1 between the two ends of the two ends and the adjacent belt guide groove 12, and there are several small holes 14 communicated with the belt guide groove 12 on the side wall of the ventilation groove 13; There are suction channels 15 and blowing channels 16 respectively in the roller shaft 1, and the ventilation slots 13 adjacent to the two sides of the belt guide groove 12 on the roller shaft 1 are respectively formed with suction channels communicating with the suction channels 15 and the blowing channels 16. Air groove holes 17 and blowing groove holes 18; several sealing pipe sleeves 3 covering the ventilation grooves 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com