A pillow-shaped low-frequency airbag vibration isolator and its installation method

An installation method and vibration isolator technology are applied in the direction of gas shock absorbers, shock absorbers, shock absorbers, etc., which can solve the problems that the vibration damping performance needs to be further improved, and achieve national defense security, superior vibration reduction and isolation performance, Good effect of vibration reduction and isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

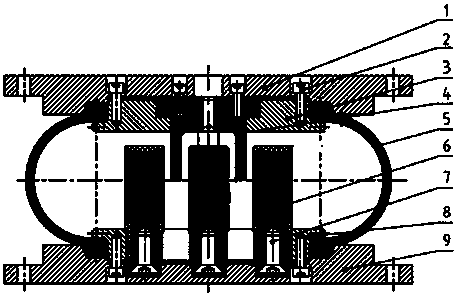

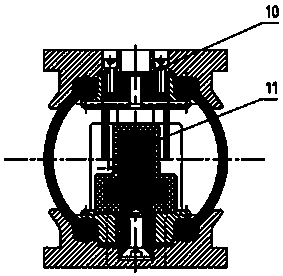

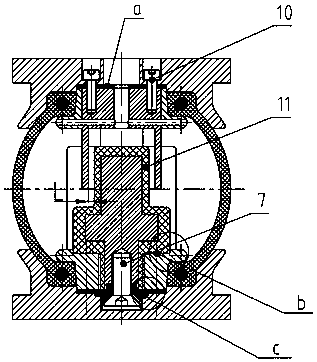

[0031] like figure 1 and figure 2 As shown, a pillow-shaped low-frequency airbag vibration isolator, the airbag 5 includes an inner rubber layer, a middle ply layer, an outer rubber layer, an upper mouth (traveler), and a lower mouth (traveler). The upper mouth of the airbag, the upper cover plate 1, and the upper buckle ring 3 pass through the conical surface (angle), and the lower mouth, the lower cover plate 9, and the lower buckle ring 8 pass through the cone surface (angle) to form a self-sealing airbag vibration isolator to close the working space , the support plate one 6 and the support plate two 11 are fixed on the lower buckle 8 by the fastening screw two 7, and the limit block 4 is fixed on the upper cover plate 1 and the upper buckle 3 by the fastening screw three 10. The upper cover plate 1 is connected to the upper buckle 3 by fastening screws 1 and 2, and the lower cover 9 is connected to the lower buckle 8 by fastening screws 1 and 2. Compressed air (or othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com