DC cable thermal cycle voltage test device

A DC cable and voltage test technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of not truly reflecting the operating status of the cable, the circulation loss of the metal sheath, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

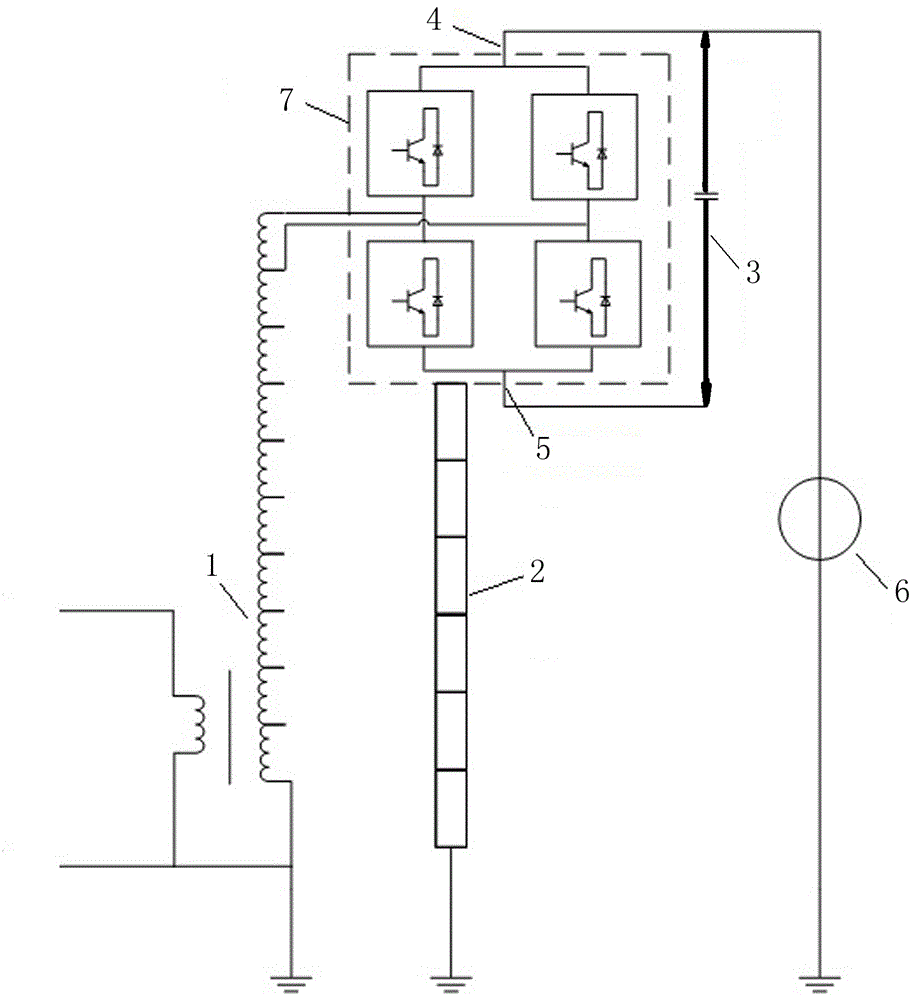

[0014] Such as figure 1 As shown, a DC cable thermal cycle voltage test device includes a step-up transformer 1, a rectifier bridge 7 electrically connected to the step-up transformer 1, and the rectifier bridge 7 is provided with a first output terminal 4 and a second output terminal 5 A test DC cable 3 is connected between the first output terminal 4 and the second output terminal 5 , and the high potential end of the test DC cable 3 is connected to a DC high voltage generator 6 . The DC heating of the test DC cable 3 is realized through the step-up transformer 1, the rectifier bridge 7 and the DC high-voltage generator 6. The simulated test conditions are consistent with the working conditions of the DC cable 3, which is more in line with the actual application conditions of the DC cable 3.

[0015] In order to provide support fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com