Fan yawing test mechanism and fan set testing bench

A test bench, fan technology, used in wind turbines, engine testing, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

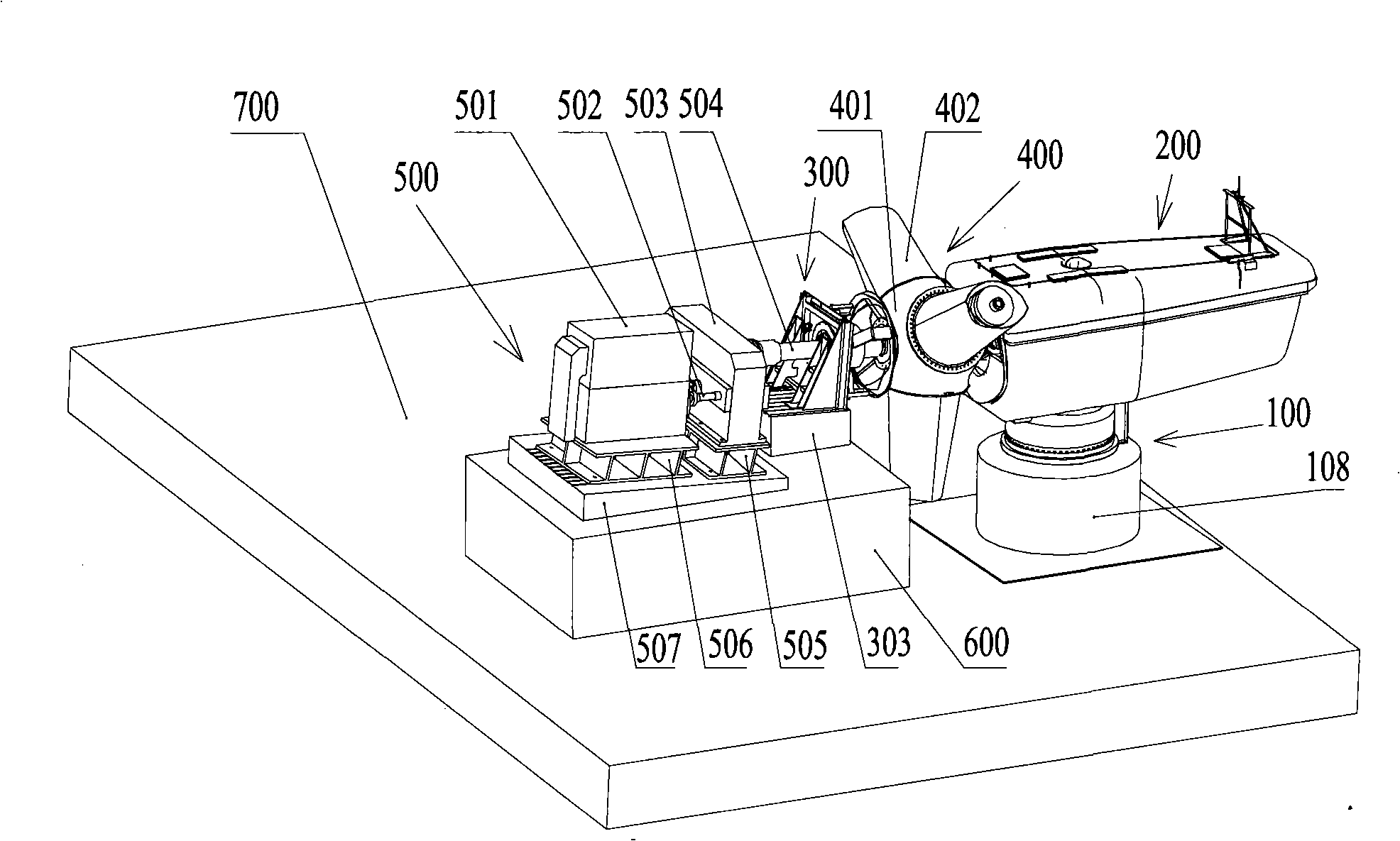

[0063] The basic idea of the present invention is to set up a wind turbine yaw test mechanism; during the wind turbine yaw test, the tower tooling rotates while the engine room is fixed; thus, the wind turbine yaw test can be performed while the prime mover drives the wind turbine to rotate.

[0064] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

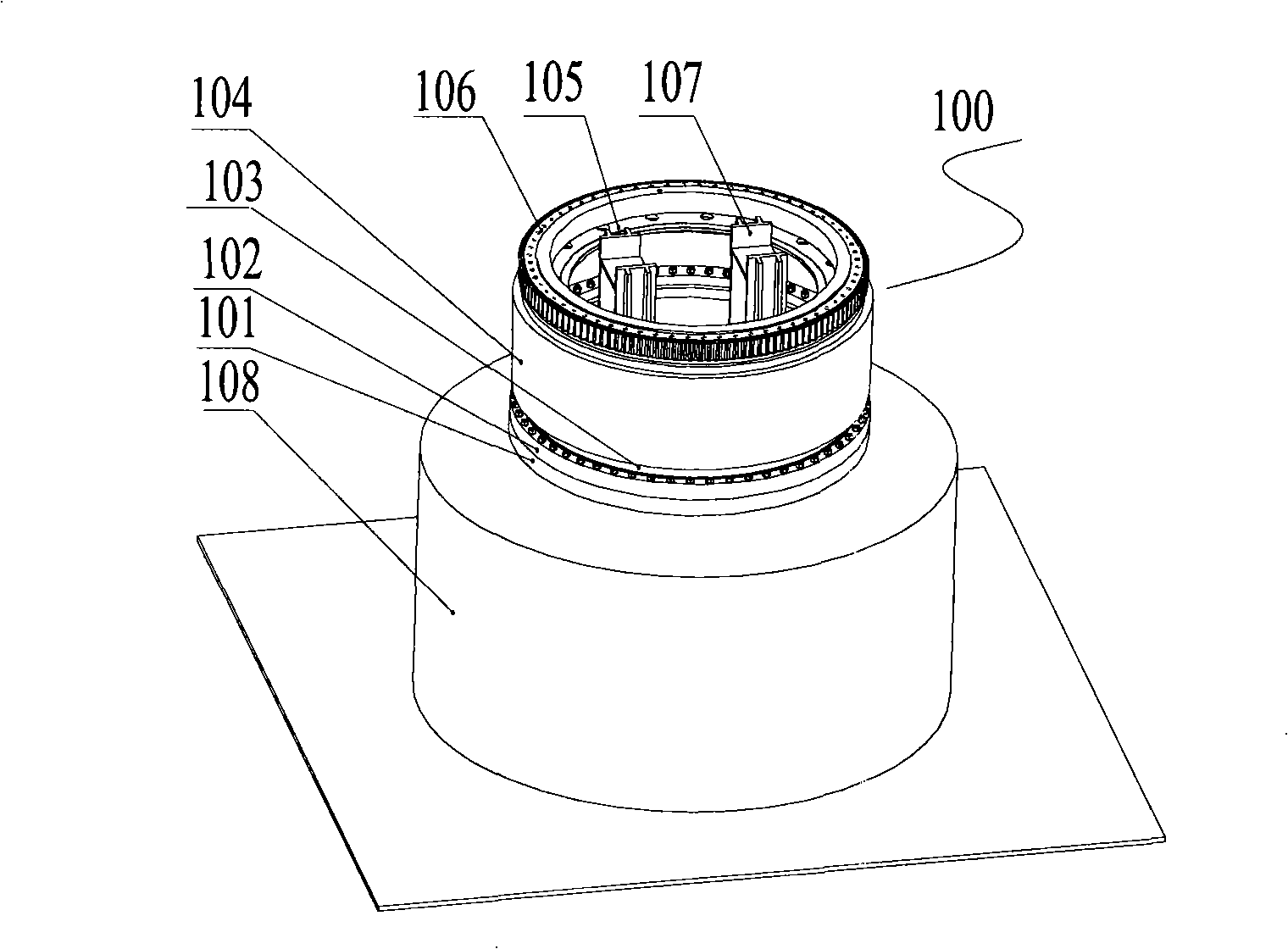

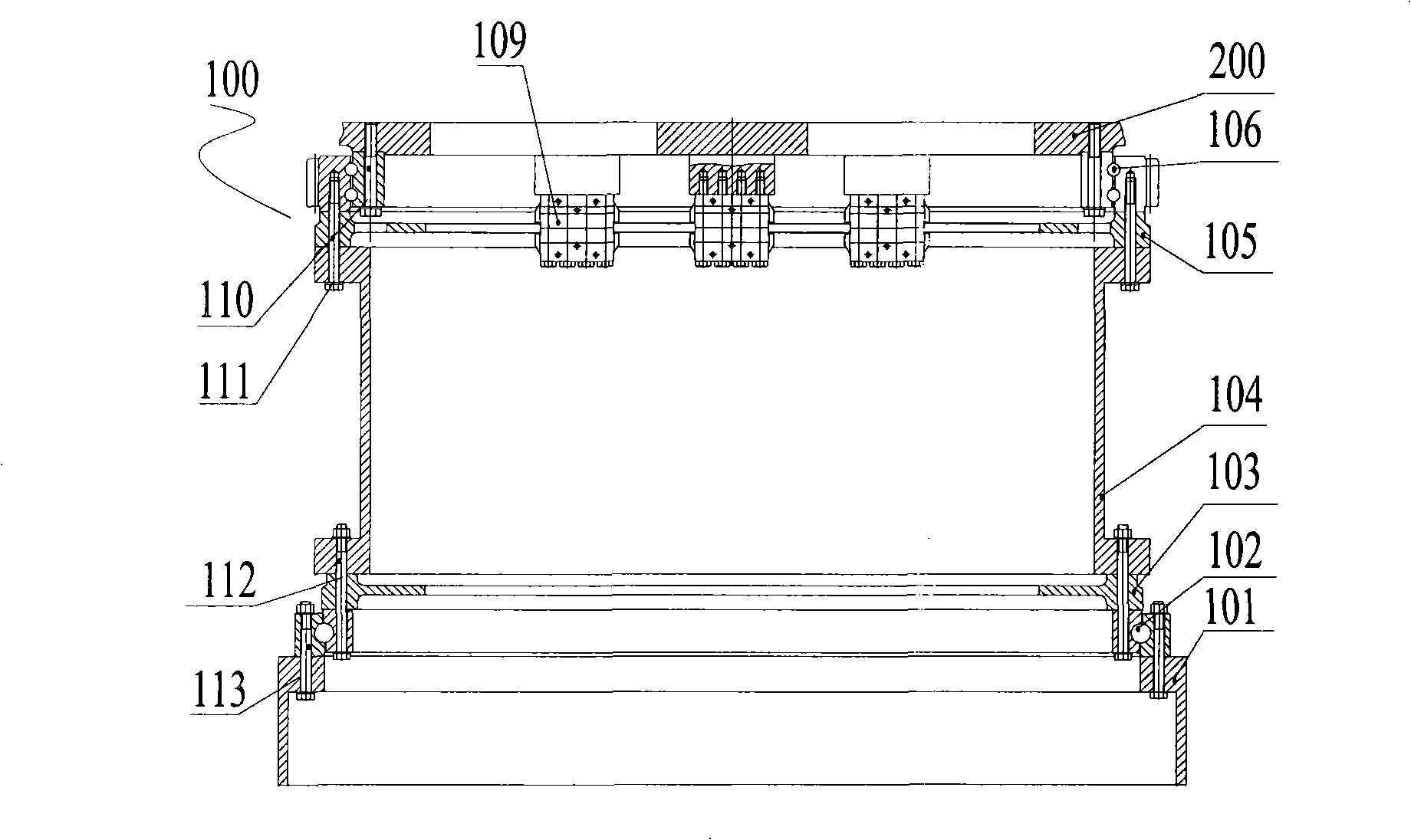

[0065] Please also see figure 1 , figure 2 ,in, figure 1 It is an axonometric view of a preferred embodiment of the fan yaw test mechanism of the present invention; figure 2 yes figure 1 Sectional view along the plane of symmetry of the wind turbine yaw test mechanism. The wind turbine yaw test mechanism 100 includes:

[0066] The nacelle support 107, the lower end is fixed on the yaw foundation 108, and the upper end is fixed to the nacelle of the fan 200;

[0067] The tower tooling 104 is connected with the tower tooling driving device (not shown) through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com