Motion path planning method

A motion path and planning technology, applied in non-electric variable control, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve the problem of tractor and trailer folding, extrusion, and path tracking control methods. The same problem, to achieve the effect of avoiding folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

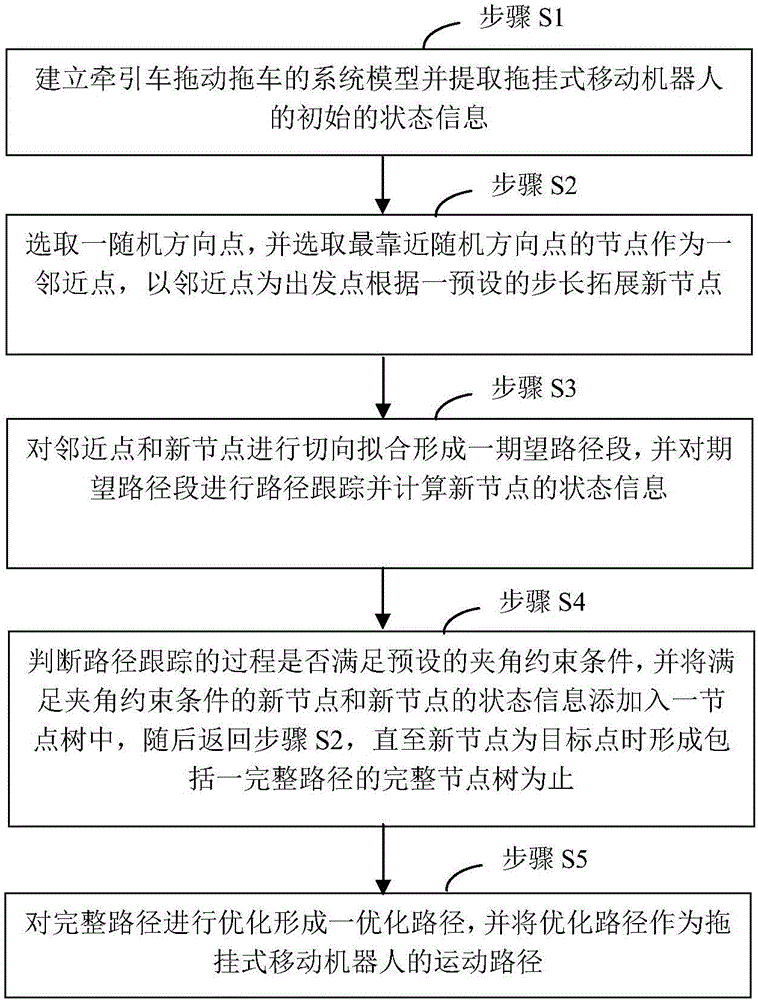

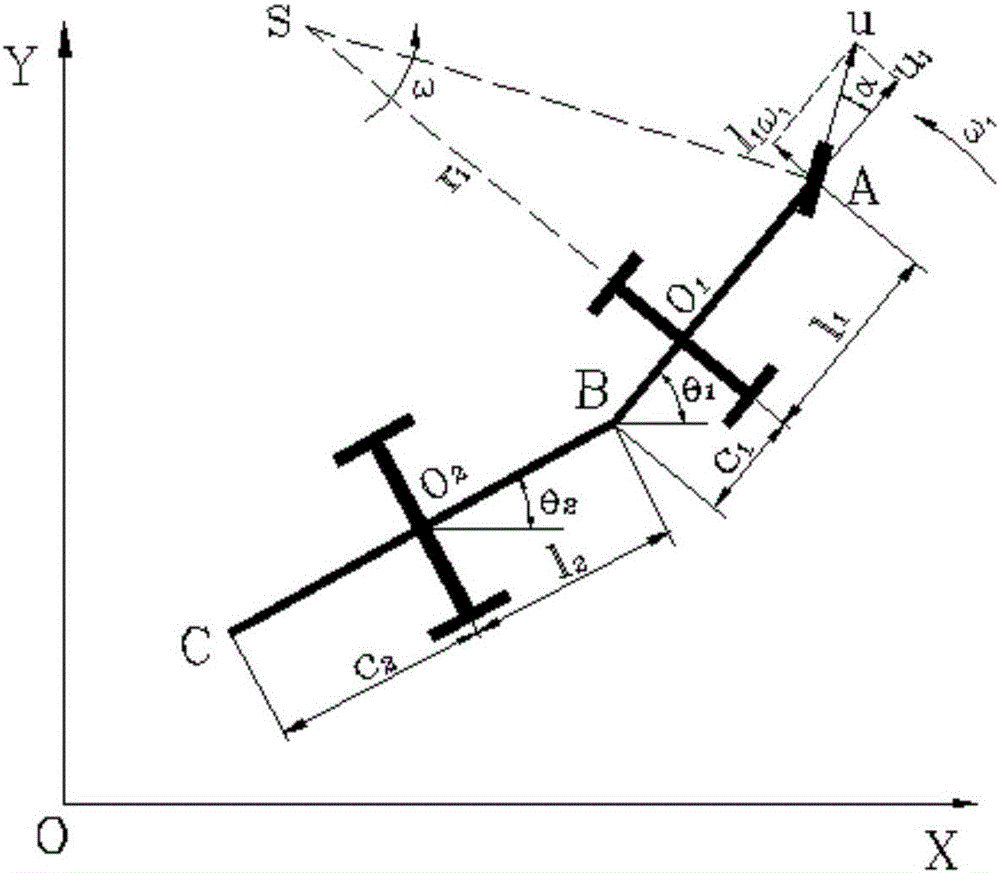

[0041] In a preferred embodiment, as figure 1 As shown, a motion path planning method is proposed, which can be applied to a trailer-type mobile robot. The trailer-type mobile robot can include such as figure 2 A tractor and a trailer are shown, and the tractor pulls the trailer to move towards a target point; the planning method may include:

[0042] Step S1: Establish the system model of the tractor towing the trailer and extract the initial state information of the trailer-type mobile robot;

[0043] Step S2: Select a random direction point, and select the node closest to the random direction point as a neighboring point, and use the neighboring point as a starting point to expand new nodes according to a preset step size;

[0044] Step S3: Perform tangential fitting on the adjacent points and the new node to form a desired path segment, and perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com