Reformable epoxy resin for composites

An epoxy resin, reshaping technology, applied in the direction of epoxy resin glue, synthetic resin layered products, applications, etc., can solve the problems that the adhesive cannot bond multiple layers, limit, and difficult strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

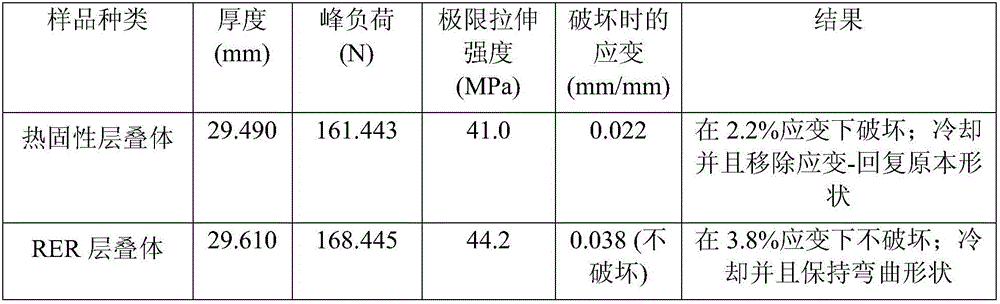

[0025] Two sheets of 1 / 8" maple were laminated each. The first sheet was laminated with a thermoset hardener comprising Araldite 1564SP epoxy and Aradur 22962 hardener (both available from Huntsman Corporation, The Woodlands, TX) in a ratio of about 4:1. Epoxy material laminated. The second sheet was laminated with RER film material (two sheets of 0.005" film) according to the present teachings. All laminates were cured in a press at 75 psi and 120°C for 15 minutes, then at 75 psi and 150°C for 2 hours. Three-point bend tests for flexural properties were performed at 85°C (according to ASTM D790). The thermoset laminate failed at 2.2% strain. The RER film stack did not fail at 2.2% strain. The RER film stack did not fail even at strains as high as 3.8%. The test was terminated at 3.8% strain due to failure of the wood material (as opposed to failure of the laminate). Thermoset laminates are thus limited by the flexibility of the thermoset epoxy, while RER laminates are lim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com