Shiitake mushroom stem cutting machine

A technology for cutting and shiitake mushrooms, which is applied in the fields of application, food processing, food science, etc., can solve the problems of slow output speed of shiitake mushrooms affecting processing efficiency, etc., and achieve the effect of increasing the probability and expanding the distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

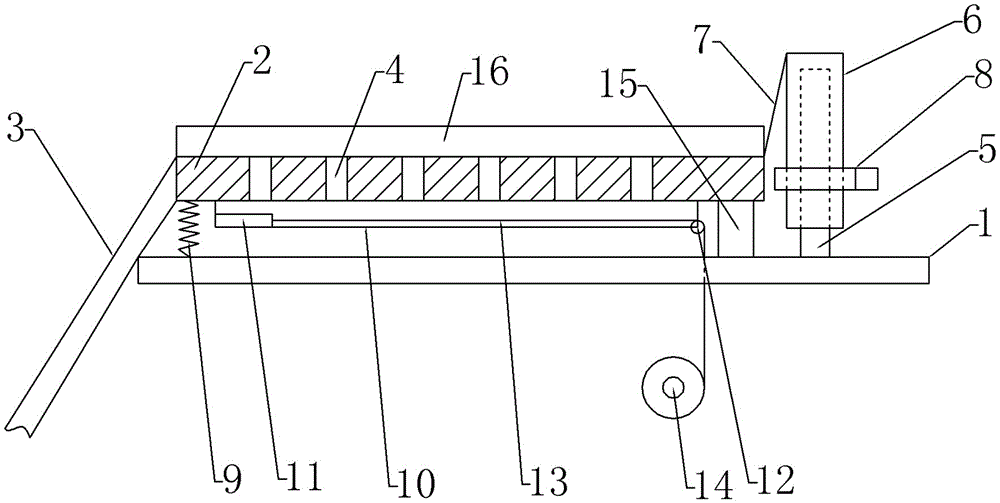

[0020] The reference signs in the drawings of the description include: frame 1, positioning plate 2, slideway 3, positioning hole 4, threaded rod 5, threaded cover 6, elastic rope 7, cam 8, spring 9, slide rail 10, cutter 11. Fixed pulley 12, control line 13, roller 14, limit block 15, baffle plate 16.

[0021] This example figure 1 As shown, a shiitake mushroom cutting machine includes a frame 1, a slideway 3 is provided on one side of the frame 1, and the top of the slideway 3 is connected with a positioning plate 2. The positioning plate 2 is rectangular, and the slideway 3 abuts against one end of the positioning plate 2 . The surface of the positioning plate 2 is provided with six rows of positioning holes 4 with a diameter of 4 cm, and each row has 5, the distance between every adjacent two rows of positioning holes 4 is the same, and two adjacent positioning hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com