An online generation method of tobacco leaf curing curve in intensive curing barn

A technology of curing process and intensive curing room, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problem of inability to realize the online generation of curing process curve, and achieves the effect of flexible and convenient implementation, good effect and reduction of labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] 以下结合具体实施例,对本发明进行详细说明。

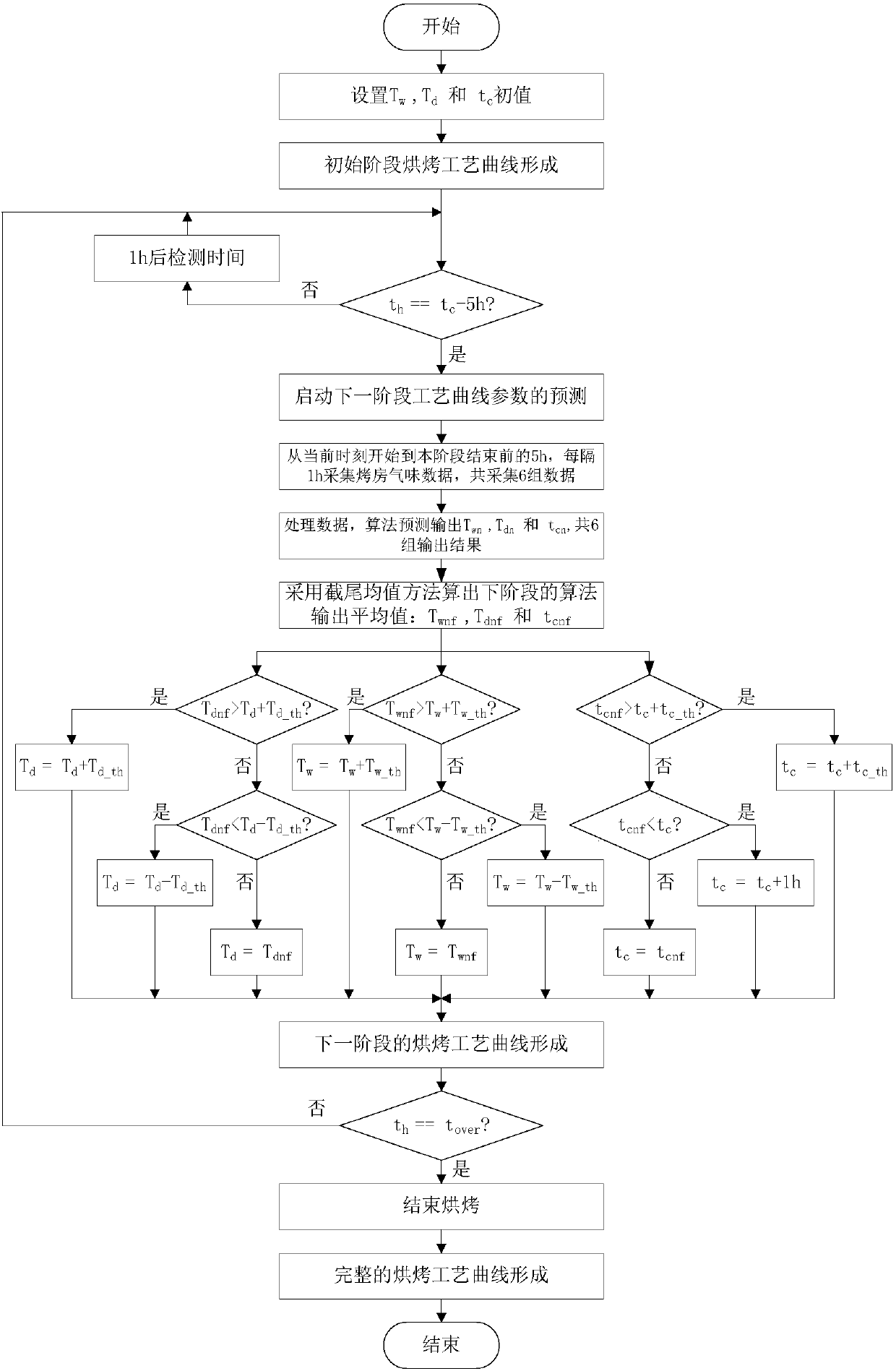

[0033] 本发明首先设置初始阶段的烘烤工艺曲线,在该阶段要结束前的5小时启动下一个阶段的烘烤工艺曲线参数预测,每隔1小时采集一次烤房气体信号并提取出气味特征,将该特征输入到训练好的RBF神经网络,预测输出烘烤工艺曲线参数,并根据他们不同的取值范围,设置下一阶段烘烤曲线参数,从而形成下一阶段的烘烤工艺曲线,重复以上步骤直到烘烤结束,实现了密集烤房烟叶烘烤工艺曲线的在线生成。

[0034] figure 1 是本发明的在线生成烘烤工艺曲线方法的总流程,具体步骤说明如下:

[0035] Step 1: Start baking, set the parameters of the baking process curve in the initial stage: dry bulb temperature T d , wet bulb temperature T w , and the end time t of the baking phase c , forming the baking process curve in the initial stage;

[0036] Step 2: Detect the current baking time t h Whether it reaches 5 hours before the end of the baking stage of this stage, if yes, go to step 3, otherwise repeat step 2 after 1 hour;

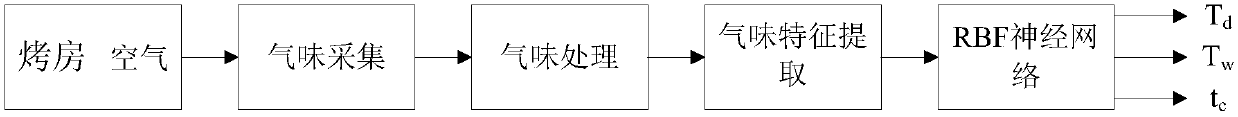

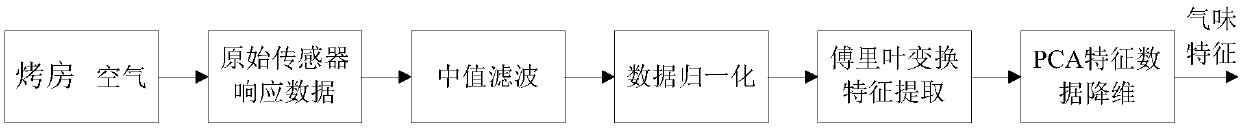

[0037] Step 3: start the prediction of the parameters of the baking process curve in the next stage. From the current moment to the 5 hours before the end of the baking phase of this stage, the gas signal of the baking room is collected every 1 hour and the odor feature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com