Rice washing equipment

A technology for washing and washing rice, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of low cleaning efficiency, high labor costs, inconvenient operation, etc., and achieve scientific and reasonable design, Good cleaning effect and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

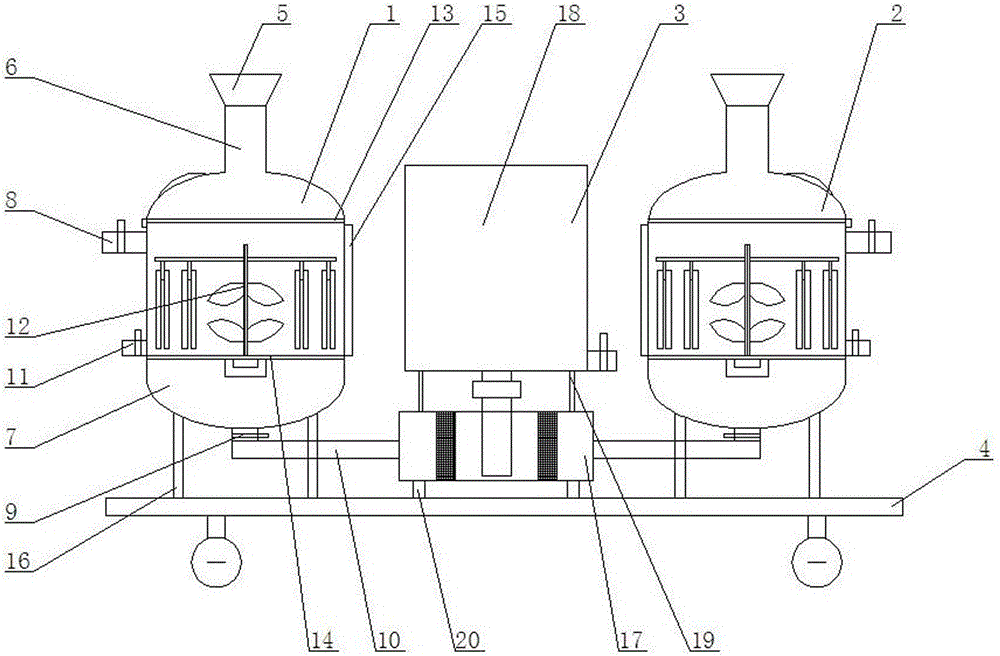

[0018] Such as figure 1 Shown, a kind of rice elutriation device comprises left cleaning impurity removal device 1, right cleaning impurity removal device 2, rice washing water recovery device 3, movable frame 4, described left cleaning impurity removal device 1, right cleaning and removal device Miscellaneous devices 2 are respectively arranged on the left side and the right side of the top of the movable frame 4, and the rice washing water recovery device 3 is arranged in the middle of the top of the movable frame 4. The left end of the rice washing water recovery device 3 is connected to the left cleaning and impurity removal device 1, and the right end Connect the right cleaning and removing impurities device 2; the structure of the left cleaning and removing impurities device 1 is the same as that of the right cleaning and removing impurities device 2.

Embodiment 2

[0020] Such as figure 1 As shown, the left cleaning and impurity removal device 1 is composed of a rice feeding bucket 5, a rice feeding pipe 6, a rice washing cylinder 7, an upper miscellaneous discharge pipe 8, a lower miscellaneous discharge pipe 9, a connecting water pipe 10, a rice outlet pipe 11, a rotary cleaning The device 12, the upper filter plate 13, the lower filter plate 14, the observation window 15, and the support frame 16 are formed. The bottom end of the rice feeding bucket 5 is connected to the rice feeding pipe 6, and the rice feeding pipe 6 is connected to the device in the middle of the top of the rice cleaning cylinder 7. , the filter plate 13 on the upper end device of the rice washing cylinder 7, the lower filter plate 14 on the inner lower end device, the rotating cleaning device 12 on the upper end of the lower filter plate 14, and the lower end device of the upper filter plate 13; the upper end device on the left side of the rice washing cylinder 7 ...

Embodiment 3

[0022] Such as figure 1 As shown, the rice washing water recovery device 3 is composed of a filter box 17, a return tank 18, an upper fixed frame 19, and a lower fixed frame 20; In the middle of the top, the upper end is fixedly supported by the upper fixing frame 19 to support the upper return water tank 18; a stainless steel metal filter cartridge is also installed inside the filter box 17; To the inner lower end of the stainless steel metal filter cartridge inside the filter box 17; the lower end of the right side of the return water tank 18 is also equipped with a drain pipe with a water control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com