Large broaching tool for one-step broaching forming

A large broach and rough drawing technology, which is applied to components with teeth, gear teeth, and gear tooth manufacturing tools, can solve problems such as unstable product quality, expensive large broaches, and complicated broach structures, and achieve Low cost, balanced broaching force, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

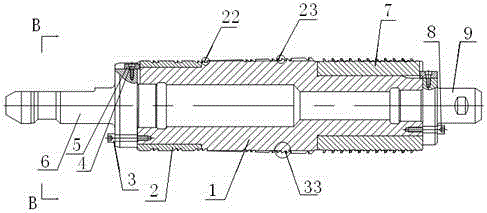

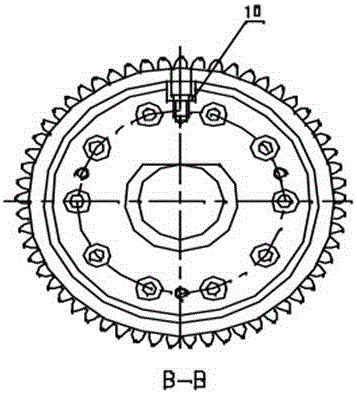

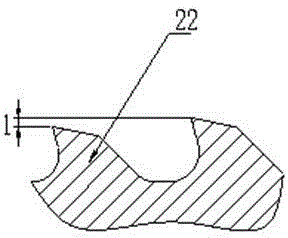

[0024] Referring to the above-mentioned drawings, a large broach formed by one drawing, including a broach body 1, a front handle 6, a rear handle 9 and fasteners, is characterized in that the broach body 1 of the broach is a cylinder shape structure, the broach is a three-stage broaching structure, the three-stage broaching structure is a rough broaching tool set 2, a tooth-expanding thick fine knife set 7 for round holes with a skip tooth structure, and a broach body 1 for spline rough drawing, That is, the front part is the rough broaching tool set 2, the middle is the spline rough broaching tool body 1, and the rear part is the tooth-expanding thick finishing tool set 7 with round holes in the skip tooth structure; the three-stage broaching structure is set to reduce the assembly link of the broaching tool , Eliminate the influence of assembly errors on the accuracy of the broach, no need to chamfer the tool sleeve, simple processing, low cost, easy assembly and disassembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com