Battery mold for large prefabricated composite wallboard

A group of vertical formwork and wallboard technology, used in molds, manufacturing tools, ceramic molding machines, etc., can solve problems such as dislocation of thermal insulation materials, inability to generate buoyancy, and inability of concrete to enter the thermal insulation board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

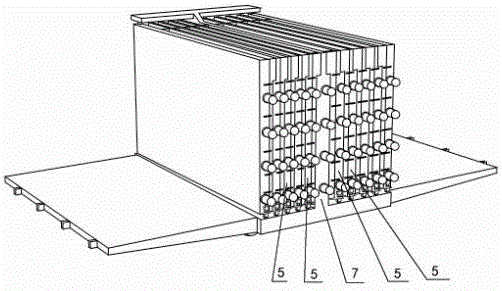

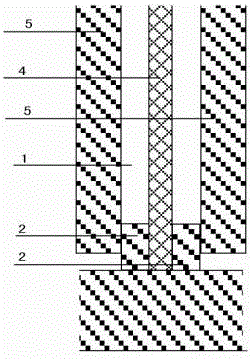

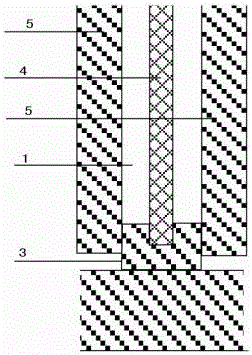

[0010] Such as figure 1 , 2 , 3, shown in 4, the present invention comprises two groups of movable molds 5 and a fixed mold 7, two groups of movable molds 5 are respectively arranged on two symmetrical sides of fixed mold 7, and the number of every group of movable molds 5 is 1-10 , two adjacent moving molds 5 and the left and right side templates form a mold cavity, the fixed mold 7 and the moving mold 5 and the left and right side templates form a mold cavity, and two bottom molds 2 are arranged at the bottom of the above two mold cavities 1 , the two bottom molds 2 are parallel to each other, and the distance between the two bottom molds 2 is consistent with the thickness of the insulation board 4, such as figure 2 As shown, the bottoms of the two mold cavities 1 can also be provided with a bottom mold 3, the cross section of the bottom mold 3 is concave, and the width of the concave groove is consistent with the thickness of the insulation board 4, as image 3 As shown;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com