Carbon fiber electric heating tile slotting equipment

A carbon fiber and ceramic tile technology, applied in grinding/polishing equipment, stone processing equipment, metal processing equipment, etc., can solve problems such as slotting at the bottom of tiles, and achieve the effect of preventing high temperature cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

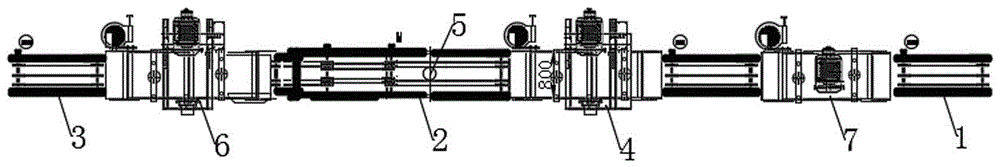

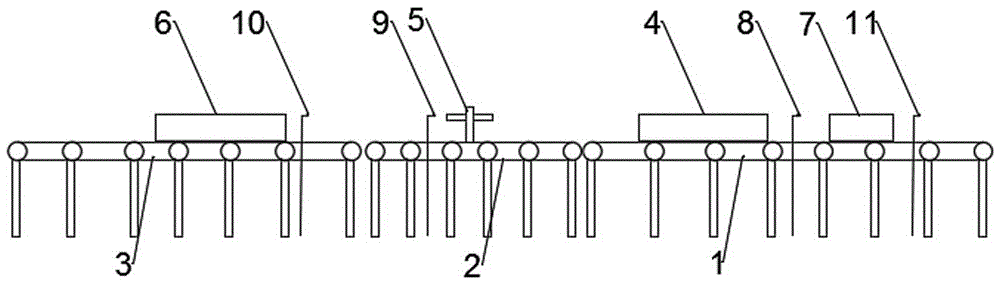

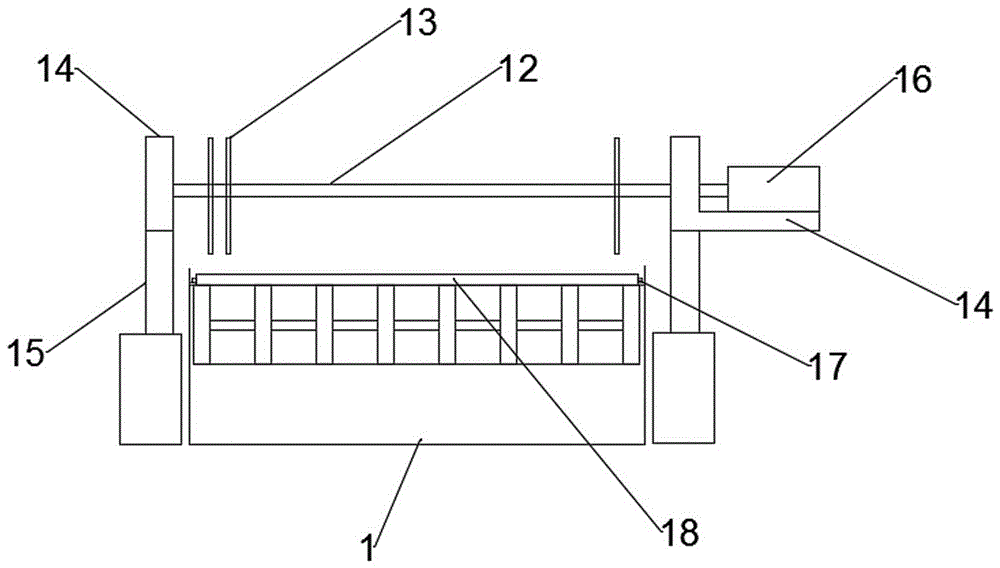

[0030] like Figure 1-6 As shown, a carbon fiber electrothermal tile throwing device includes a feeding conveying device 1, a first throwing device 4, an intermediate conveying device 2, a rotating device 5, a discharging conveying device 3 and a second throwing device 6;

[0031] The first trough throwing device 4 is arranged on the feeding conveying device 1, and is used for the first trough throwing of the tiles;

[0032] The rotating device 5 is a sucker-type rotating device, which is used to rotate the tiles after the first groove throwing by 180°;

[0033] The second groove throwing device 6 is arranged on the discharge conveying device 3, and is used to throw the tiles for the second time;

[0034] Both the first throwing tank and the second throwing tank are carried out in a water environment, and the whole set of equipment is located in a pool, and the bottom of the pool is connected to a secondary pool through a filter port, so as to recycle water resources;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com