Bottle rotating mechanism and damage-free bottle feeding device adopting same

A technology for rotating bottles and bottles, which is applied in the field of non-damaging bottle feeding devices, and can solve problems such as scratches, affecting product appearance, and relative pressure differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

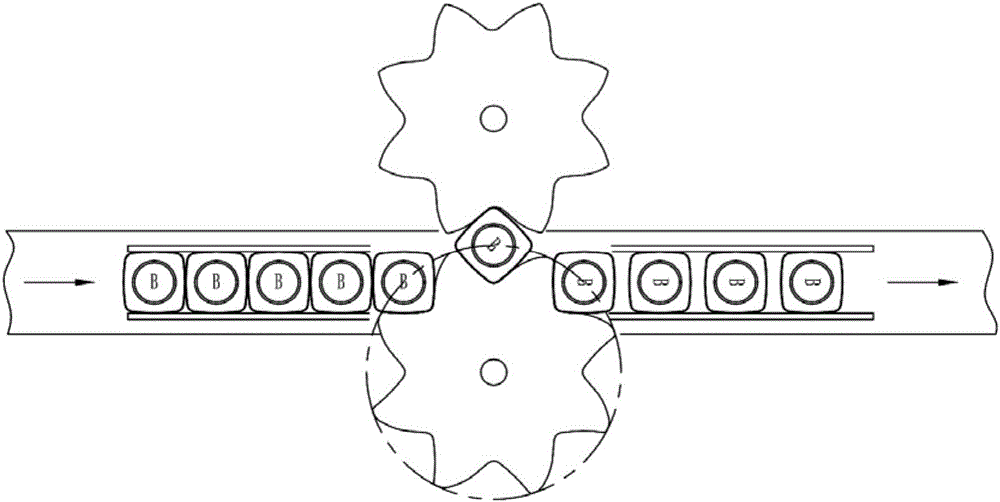

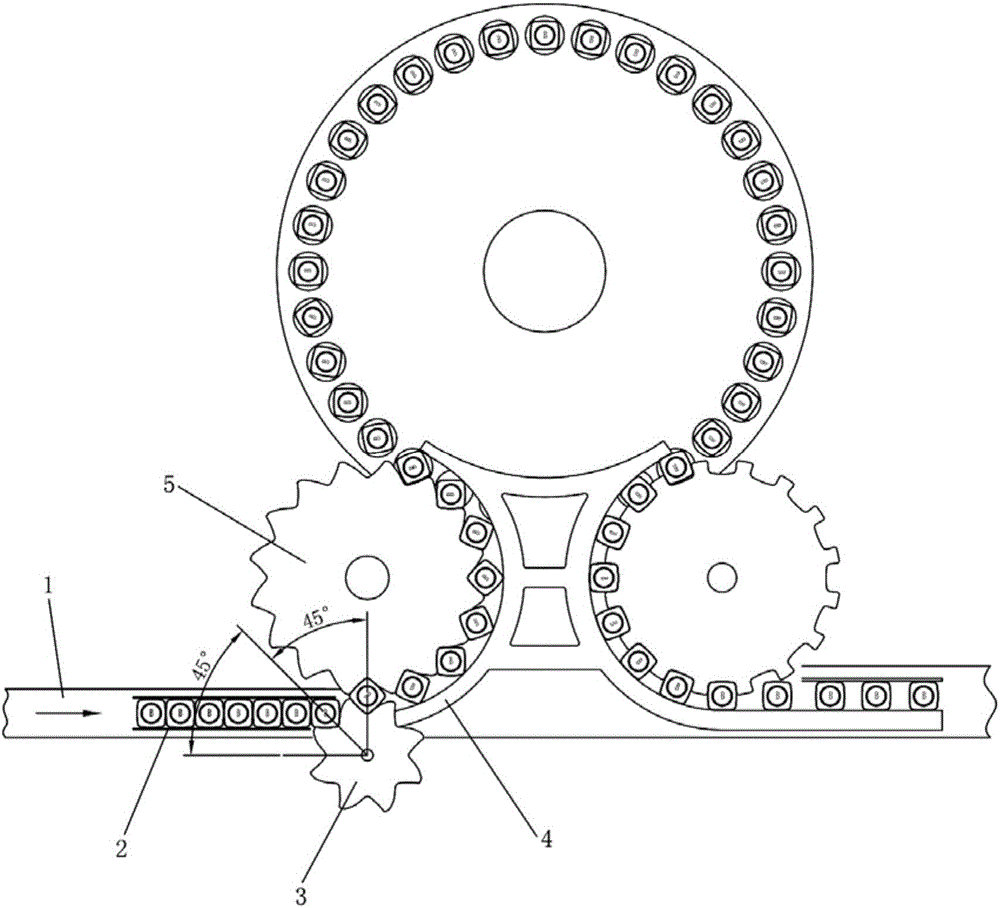

[0018] Such as figure 1 As shown, the bottle rotating mechanism is composed of a pair of star-shaped thumbwheels. The line connecting the centers of the two star-shaped thumbwheels intersects with the advancing direction of the bottle. degree etc. There are several tooth slots on the circumference of the star-shaped dial, and the space between the two star-shaped dials facing each other is just enough to accommodate a bottle, and the center of the bottle falls on the circumscribed circle of one of the star-shaped dials superior.

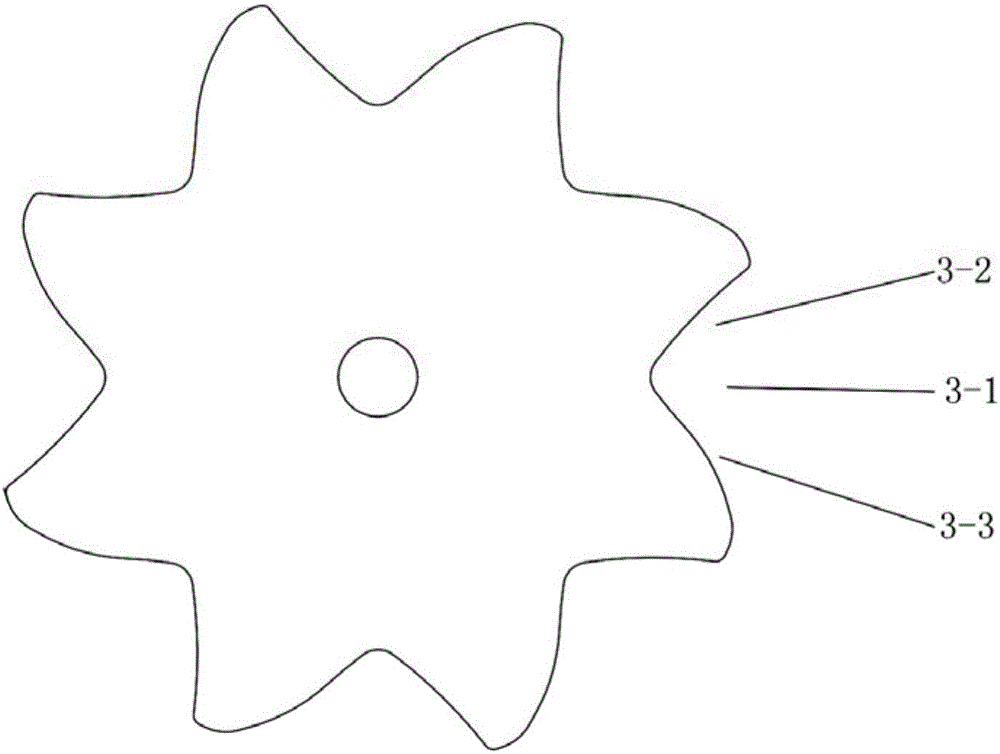

[0019] The inner surface of the alveolar is consistent with the profile of the bottle, which can be circular, square or polygonal. For example figure 2 As shown, when the bottle is square, the inner surface of the alveolar 3-1 is formed by two arc edges, and the arc edges match the shape of the bottle. The arc edge is divided into an outer convex arc edge 3-1 and an inner concave arc edge 3-2. The other parts of the tooth groove except the arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com