Textile fabric cleaning device and cleaning method of the same

A textile cloth and cleaning device technology, which is applied in the direction of textile material processing equipment configuration, textile material processing, textile material carrier processing, etc., can solve problems such as poor cleaning effect and cloth wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with accompanying drawing, the present invention is described as follows.

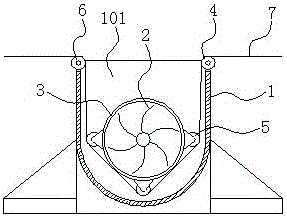

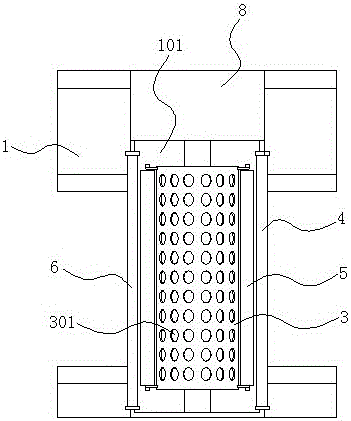

[0015] like figure 1 , figure 2 As shown, the textile cloth 7 cleaning device includes a frame 1, a motor assembly 8, a blade stirring wheel 2, and a protective drum 3. A water storage chamber 101 is formed in the frame 1, and the protective drum 3 is cylindrical, and the blade stirring wheel 2 Placed in the protective drum 3 and not in contact with the inner wall of the protective drum 3 , the cylinder surface of the protective drum 3 is evenly provided with water holes 301 . The blade stirring wheel 2 and the protective drum 3 are placed together in the water storage chamber 101, wherein the two ends of the wheel shaft of the blade stirring wheel 2 are rotated and positioned on the frame 1 at both ends of the water storage chamber 101, and one end of the wheel shaft is rotated and sealed with the frame 1, and Stretch out frame 1 and drive connection with motor assembly 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com