Offshore wind power platform provided with high-strength pile legs

An offshore wind power, high-strength technology, applied in the field of marine engineering, can solve the problems of no design ability, many ships, difficult positioning, etc., and achieve the effect of large carrying capacity, low maintenance cost, and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific embodiments.

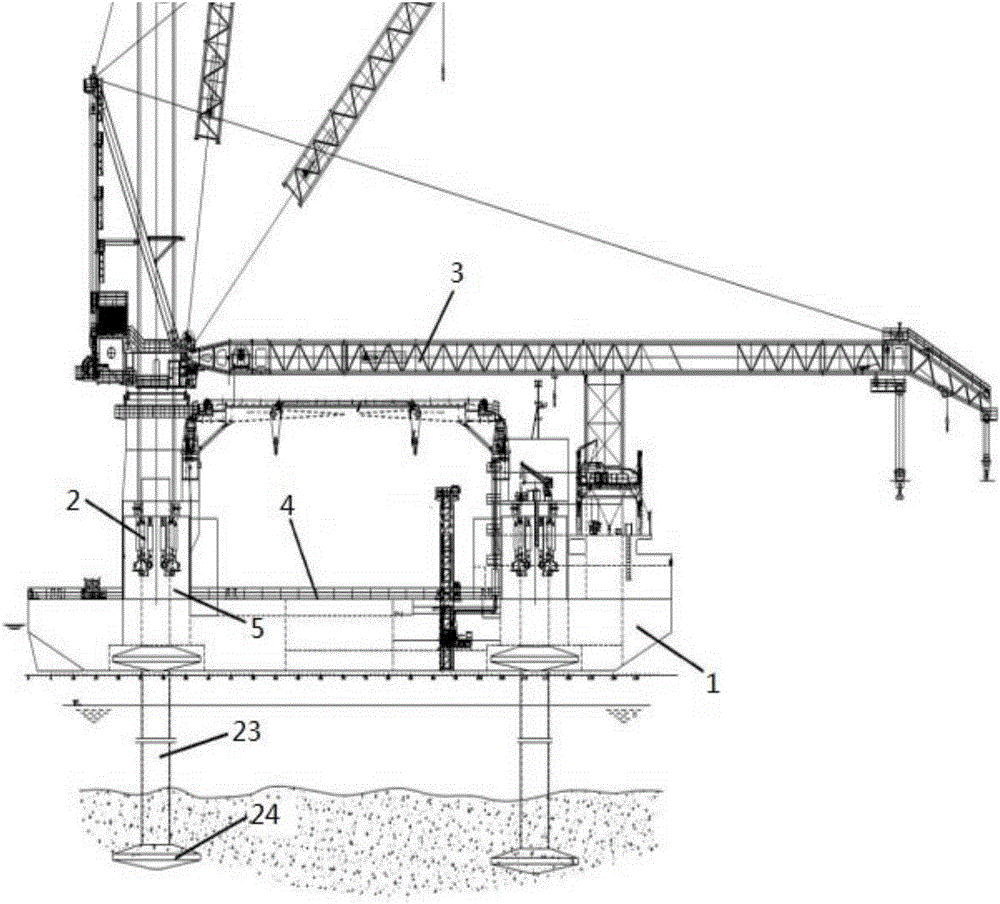

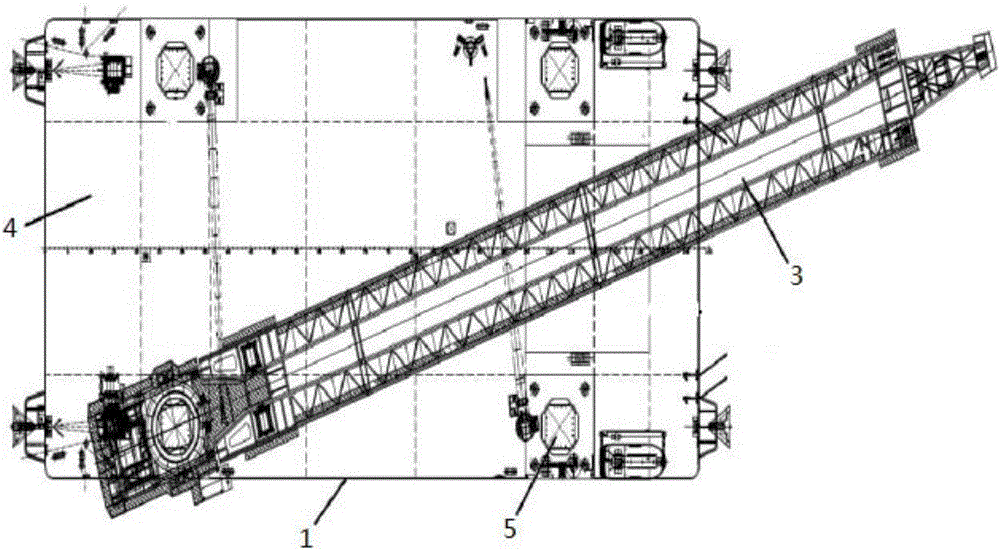

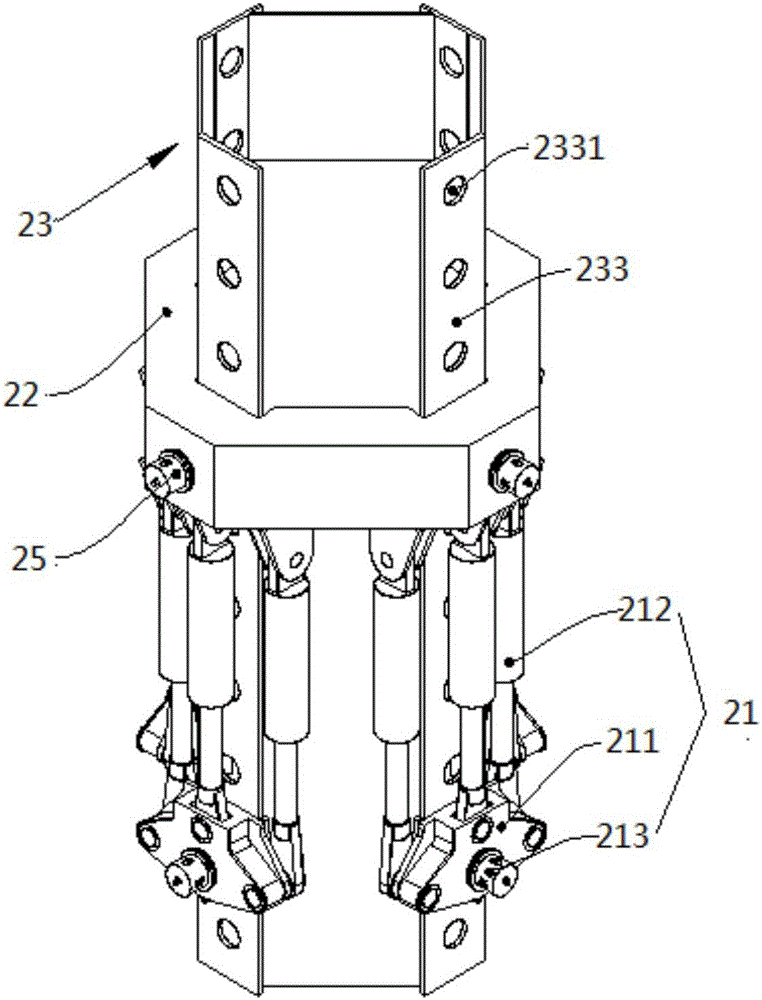

[0039] An offshore wind power platform with high-strength pile legs, comprising a hull 1, a lifting system 2, a hoisting mechanism 3, and a pile fixing chamber 5; the hull 1 is provided with a deck 4; the pile fixing chamber 5 is provided on the deck On both sides of 4, the lifting system 2 is arranged inside the pile fixing room 5; the lifting system 2 includes a lifting device 21, a fixed ring beam 22, a pile leg 23 and a pile shoe 24, the pile leg 23 Inserted into the fixed ring beam 22, the lifting device 21 is arranged on the fixed ring beam 22, the pile shoe 24 is arranged at the lower end of the pile leg 23, the pile leg 23 is sleeved Inside the pile fixing chamber 5, the hoisting mechanism 3 is installed at the top end of the pile fixing chamber 5; the pile leg 23 includes a platform partition 231, a wall 232 and a guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com