Air pressure split foundation strengthening treatment structure and method adopting air pressure split foundation strengthening treatment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

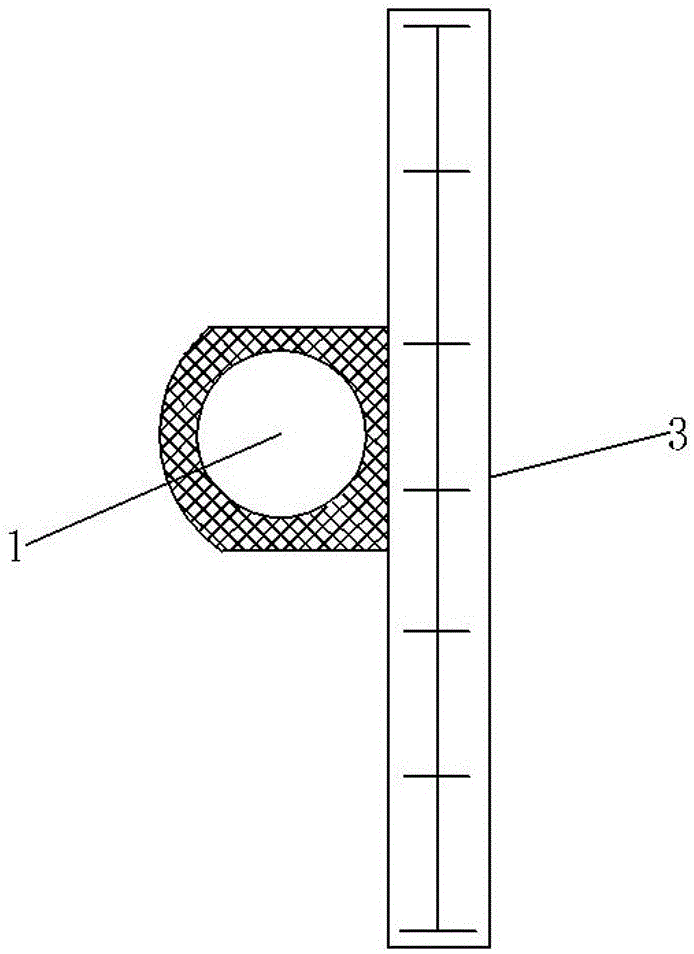

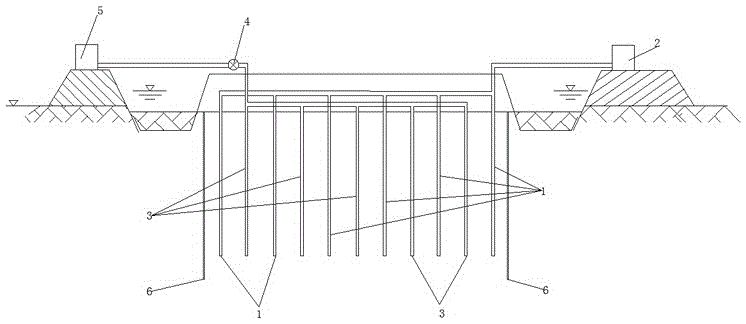

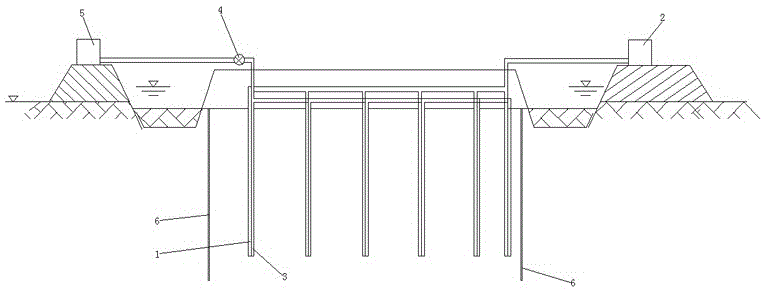

[0016] refer to figure 1 As shown, the air pressure splitting foundation reinforcement treatment structure provided by the first embodiment of the present invention includes a vacuum preloading and sealing treatment system for the soil body in the construction area and a high-pressure gas injection system, and the high-pressure gas injection system includes The high-pressure gas injection pipe 1 and the high-pressure gas injection device 2 are provided, and an exhaust and drainage plate 3 is punched in the soil body of the construction area. The exhaust and drainage plate 3 has a discharge end connected to the outside world, and the discharge end is configured with Valve 4. After the high-pressure gas is injected, it is generally only necessary to open the valve 4 to discharge the water and gas together. However, in order to improve the suction and discharge effect, a suction and discharge device 5 can also be connected to the discharge end. There is a water-stop curtain 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com