Side-vertical integral forming structure and method of shear steel plate and steel mesh on one side

A shear steel plate and integral forming technology, which is applied to building components, building structures, walls, etc., can solve problems such as difficult construction quality assurance, poor installation accuracy, and high safety risks, so as to improve processing accuracy and connection accuracy, and improve construction Efficiency, the effect of guaranteeing the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

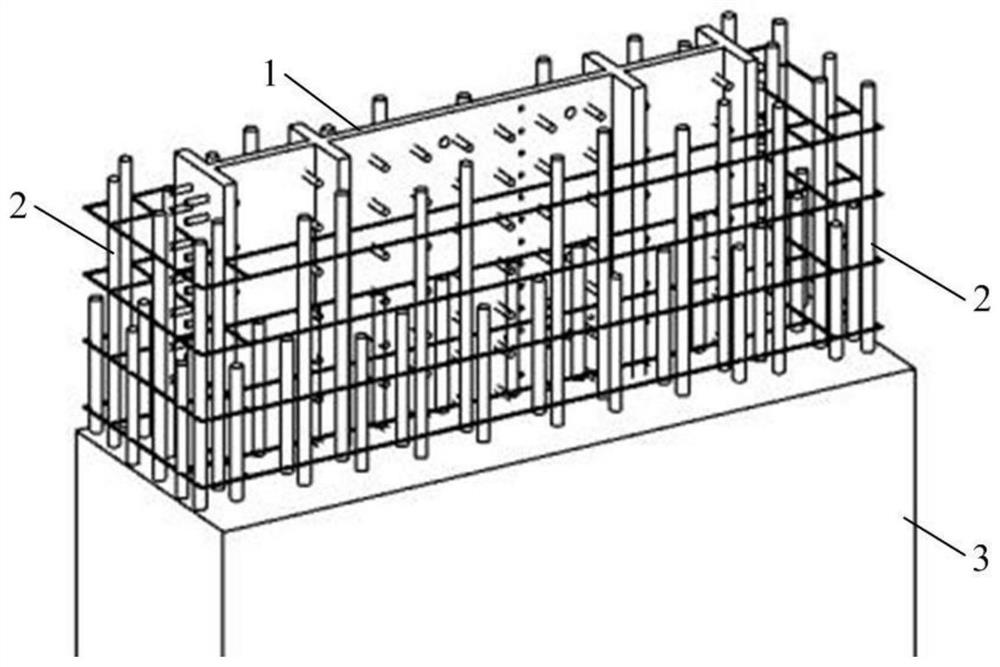

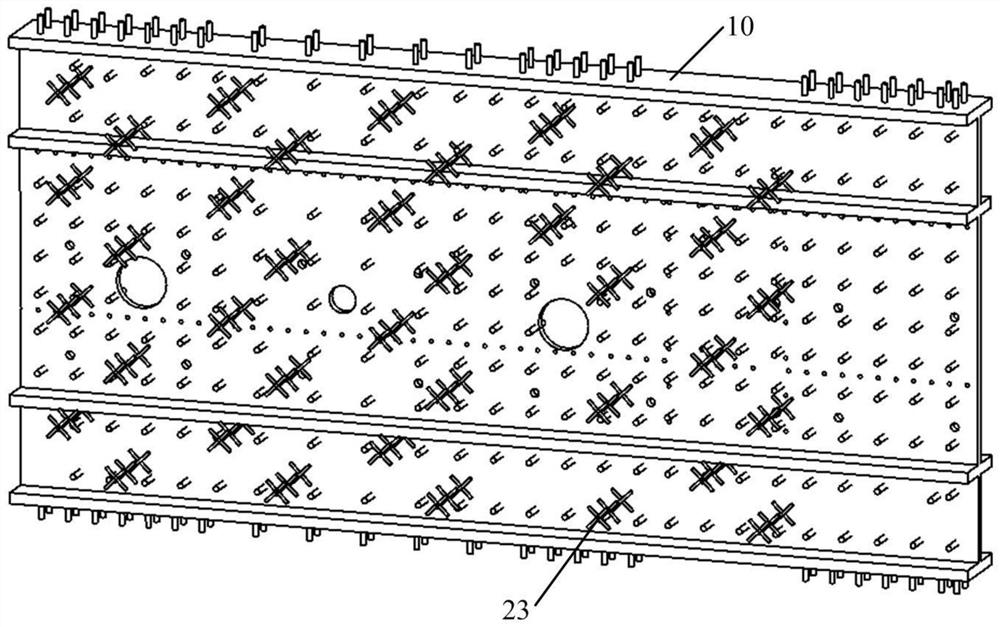

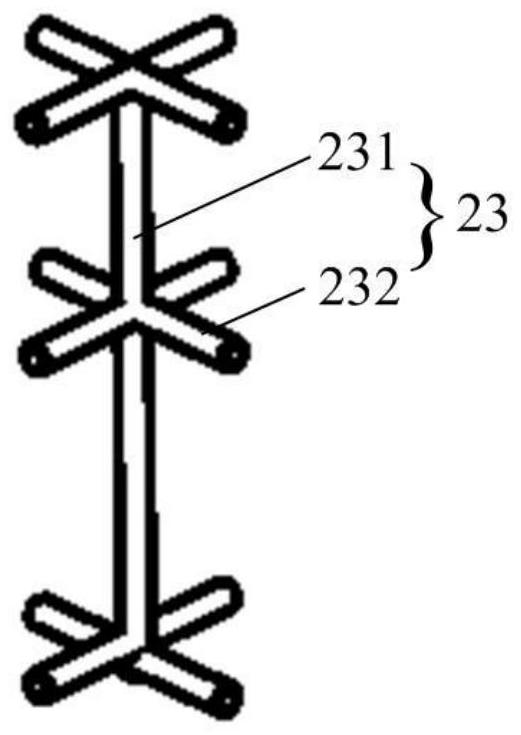

[0033] Example 1: Combining Figure 9 The side vertical integral forming structure 100 of the shear steel plate and one side of the reinforcement mesh of the present invention is described. It includes several sections of shear steel plates 10 connected to each other. Reinforcement mesh 20; a number of reinforcement positioning brackets 23 are vertically fixed on the above-mentioned shear steel plate 10, and the reinforcement mesh 20 is fixed with the reinforcement positioning bracket 23, that is to say, the reinforcement mesh 20 is connected to the shearing steel plate 10 through the reinforcement positioning bracket 23 as a whole. . The side-vertical integral forming structure 100 of the shear steel plate and the reinforcement mesh on one side, the shear steel plate 10 and the reinforcement mesh 20 on one side are prefabricated as a whole and then hoisted, which can prevent the shear steel plate 10 from being deformed during the hoisting process; Moreover, the prefabricated...

Embodiment 2

[0037] Example 2: Combination Figure 2 to Figure 9 Describe the side vertical integral forming method of the shear steel plate and one side steel mesh of the present invention, and the specific steps are as follows:

[0038] One, if figure 2 As shown, make the shear steel plate 10 stand on the horizontal plane and temporarily fix it, and vertically fix several rows of reinforcement positioning brackets 23 along the length direction of the shear steel plate 10; Figure 4 As shown, along the width direction of the shear steel plate 10, a number of reinforcing bar limit plates 24 are arranged;

[0039] Second, if Image 6 As shown, several layers of vertical steel bars 25 are arranged along the length direction of the shear steel plate 10, and the vertical steel bars 25 are fixedly connected with the steel bar positioning bracket 23, and the vertical steel bars 25 penetrate through the through holes 241 of the steel bar limit plates 24, such as Figure 7 As shown, several la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com