Old goaf underlying close distance coal seam strata-overlying isolation grouting filling exploitation method

A technique for isolating grouting and mining methods, which is applied in ground mining, earth drilling, underground mining, etc., and can solve problems such as damage, inability to achieve protection, and affect mine production safety, so as to improve control effects and eliminate residual cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] An embodiment of the present invention is further described below in conjunction with accompanying drawing:

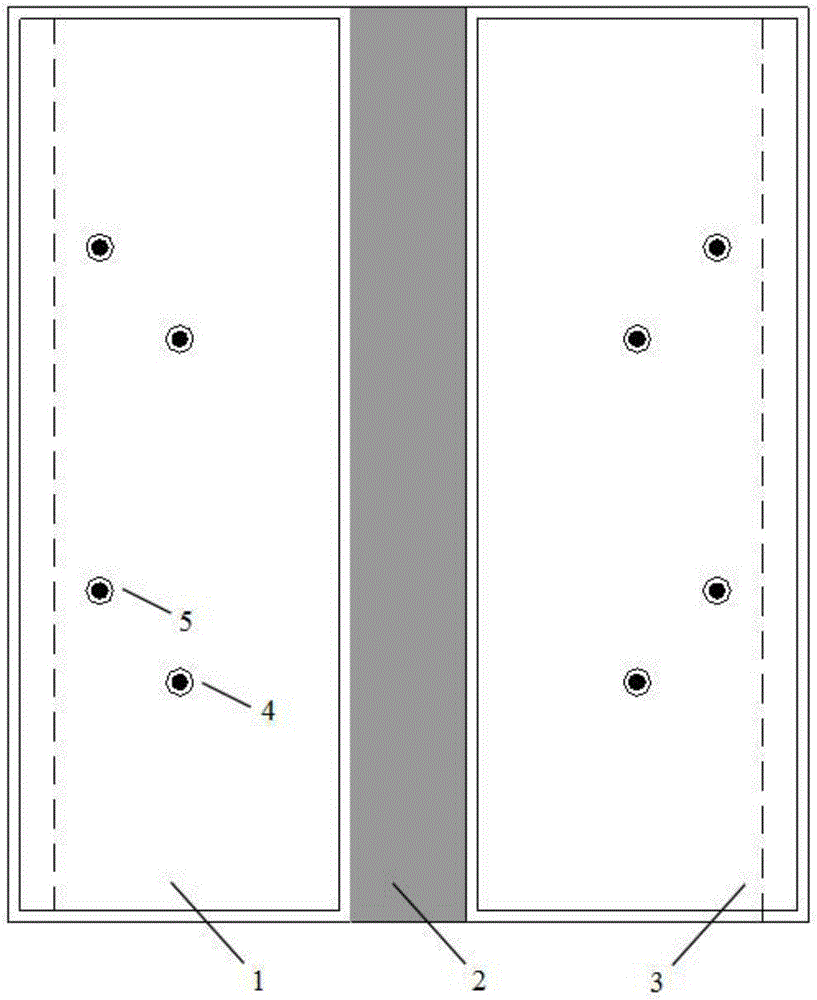

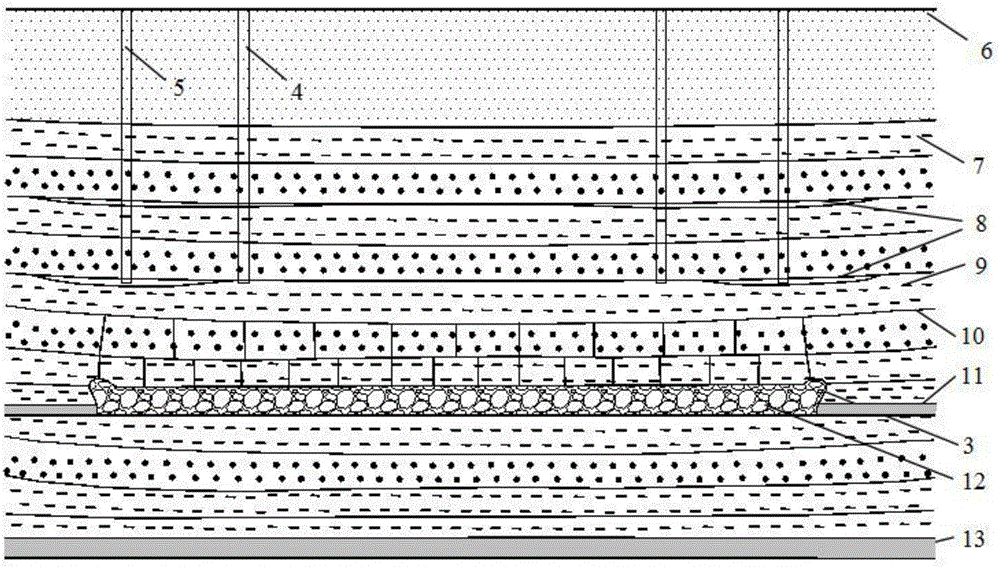

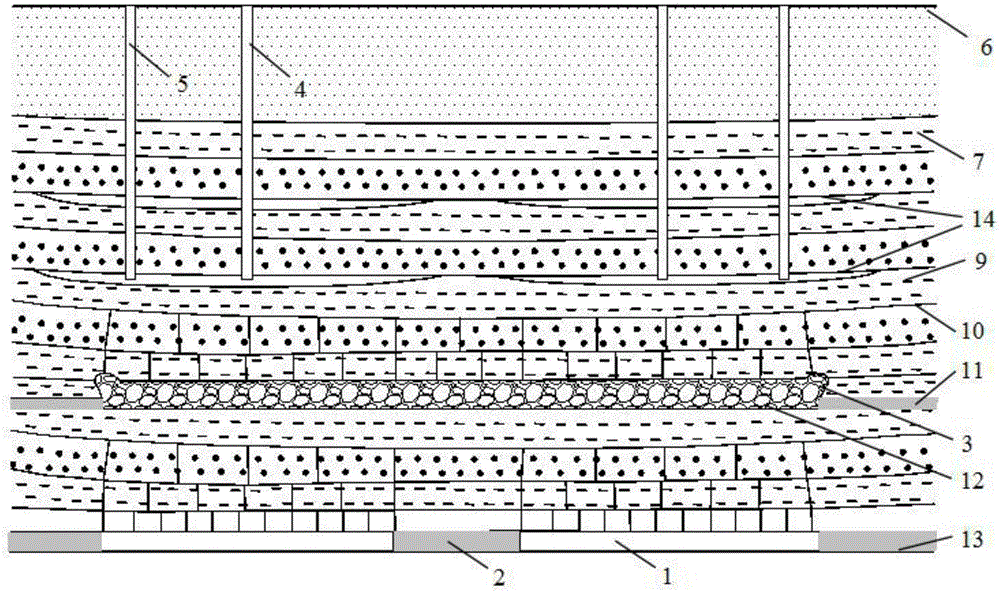

[0021] (1) Divide the mining area of the lower coal seam into several working faces 1, and leave isolated coal pillars 2 between the working faces, and construct several groups of injectors in the direction of the coal seam 13 on the ground surface 6 above several coal mining working faces 1 in sequence. Grouting holes, each group of drilling holes contains a main grouting hole 4 and an auxiliary grouting hole 5. The position of the auxiliary grouting borehole 5 of each group is adjusted according to the goaf boundary 3 of the upper coal seam (main grouting borehole 4 position is constant), and the auxiliary grouting borehole 5 is arranged in the goaf 12 of the upper coal seam and The distance from the goaf boundary 3 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com