Method for grouting, filling and compacting goaf filling body from roof roadway

A goaf and backfill technology, which is applied to backfills, mining equipment, earthwork drilling, etc., can solve problems such as the inability to achieve the expected effect of surface subsidence control, the transfer of subsidence space to the surface, and the inadequacy of backfill compaction. , to achieve the effect of simple and flexible implementation, small impact on ground production activities, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

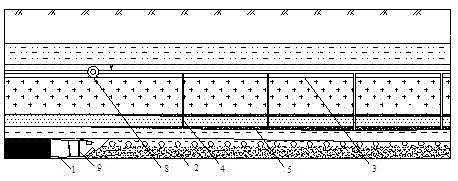

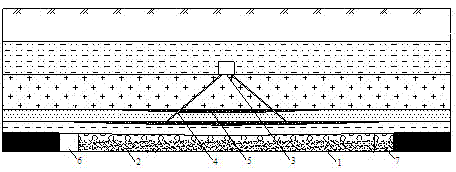

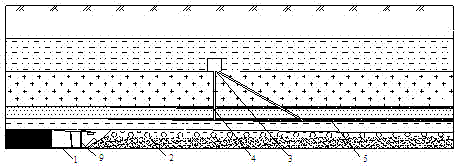

[0022] Such as figure 1 with figure 2 As mentioned above, a working face support 9 is provided on the coal mining face 1, and the gangue filling body 2 is filled in the goaf in the roadway behind the coal mining face 1, and the upper and lower grooves 6 and 2 are respectively left on both sides of the coal mining face 1. Down slot 7;

[0023] A method for filling a compacted goaf filling body by grouting from a roof roadway, comprising the following steps:

[0024] a. For every excavation distance L meters of the coal mining face, a group of grouting boreholes 4 are arranged in the goaf in the roof roadway 3 consistent with the coal mining face, and the coal mining face excavation distance L=h / tanψ, In the formula, h is the distance between the roof roadway 3 and the coal seam, and ψ is the full mining angle of the strike. Each group of grouting borehol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com