A device and method for mining overlying rock isolation and grouting filling drilling through-holes

A technology for isolating grouting and grouting drilling, which is used in fillings, safety devices, mining equipment, etc. The effect of avoiding scrapping and high penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

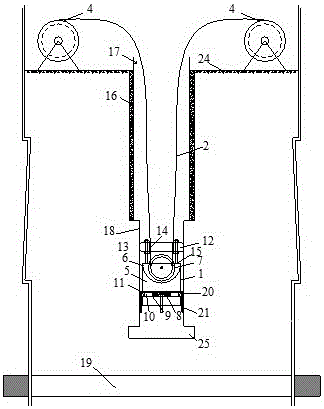

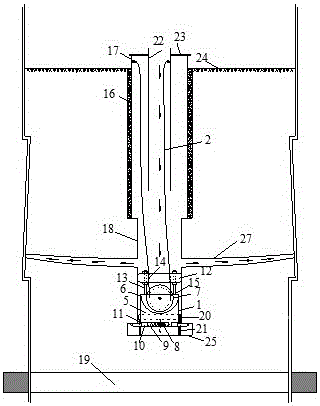

[0025] Below in conjunction with accompanying drawing and the present invention is described further:

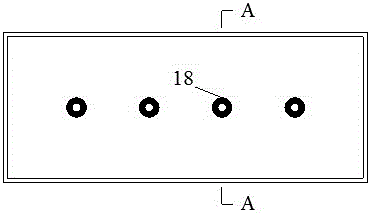

[0026] like figure 1 and figure 2 As shown, the mining overlying rock isolation grouting filling drilling through-hole device of the present invention is characterized in that it includes a hole bottom fixing device 1 installed at the bottom of the grouting filling drilling hole and is arranged on two sides of the grouting filling drilling hole. There are two winches 4 on the surface 24 of the side coal mining face, and a steel cable 2 is arranged between the hole bottom fixing device 1 and the two winches 4;

[0027] The hole bottom fixing device 1 includes a steel cylindrical base 5, a pulley groove 6 is horizontally opened in the middle of the top of the base 5, a fixed pulley 7 is arranged through a bearing in the pulley groove 6, and a steel cable groove is arranged on the fixed pulley 7 15. The top of the base 5 is provided with a cylindrical rubber plug 12 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com