Totally-enclosed fluid transmission mechanism

A fluid transmission mechanism, fully enclosed technology, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve problems that have not been resolved, affect transmission efficiency, and working medium leakage, and achieve simple structure and high transmission efficiency , to prevent the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

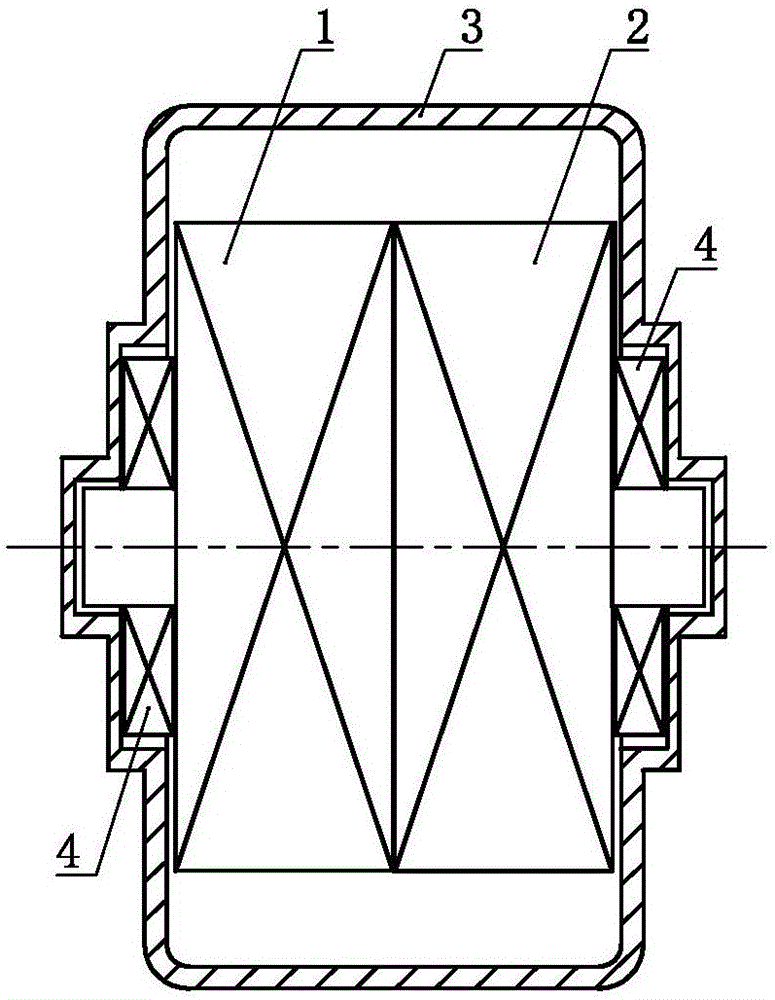

[0060] A fully enclosed fluid transmission mechanism, such as figure 1 As shown, it includes a structure A 1, a structure B 2 and a sealed casing 3, the structure A 1 and the structure B 2 are arranged in the sealed casing 3, the structure A 1 and the sealed casing 3 Said structure B2 is arranged correspondingly, and the fluid flow space comprising the fluid channel on said structure A1 and the fluid channel on said structure B2 forms a fluid circuit; between said structure A1 and said structure B Electromagnetic zone 4 is all set on 2.

[0061] As an alternative embodiment, embodiment 1 can also selectively choose to set the electromagnetic region 4 on one of the structure A 1 and the structure B 2; and can further selectively make the structure The other one of the body A 1 and the structure body B 2 is arranged in mechanical connection with the sealed casing 3 .

[0062] As an alternative embodiment, the corresponding arrangement of the structure A 1 and the structure B 2...

Embodiment 2

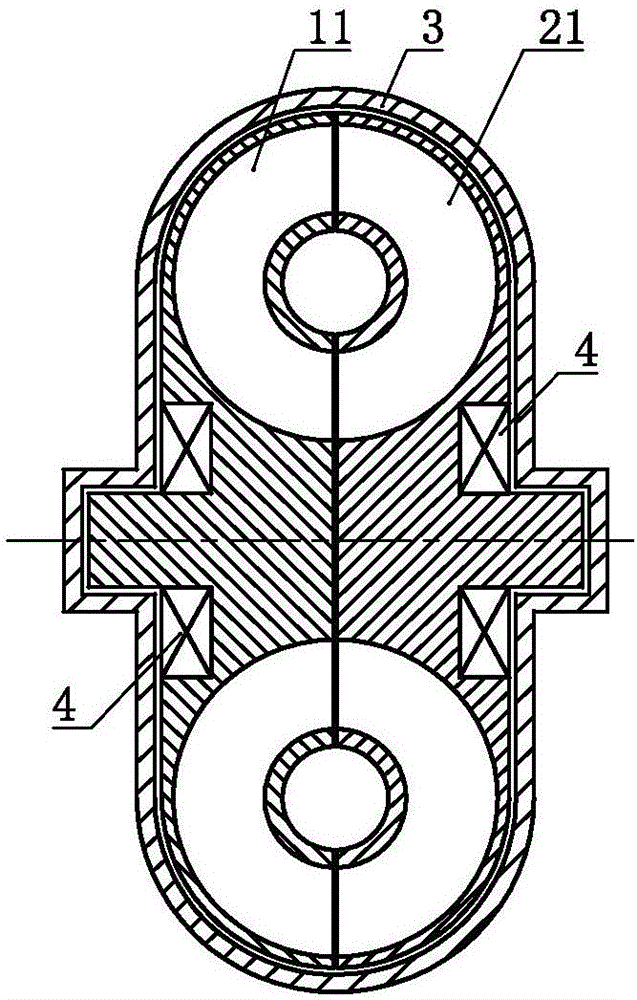

[0064] A fully enclosed fluid transmission mechanism, such as Figure 2.1 and 2.2 As shown, on the basis of Embodiment 1, the structure A1 is further set as the impeller mechanism A11, and the structure B2 is set as the impeller mechanism B21.

[0065] As a changeable implementation manner, the changeable implementation manners of Example 1 of the present invention can further set the structure A1 as the impeller mechanism A11, and the structure B2 as the impeller mechanism B21.

[0066] As a transformable embodiment, Embodiment 2 of the present invention and its transformable embodiments can further selectively choose to set the impeller mechanism A 11 as axial flow or radial flow and / or the impeller mechanism B 21 as axial flow type or radial type.

Embodiment 3

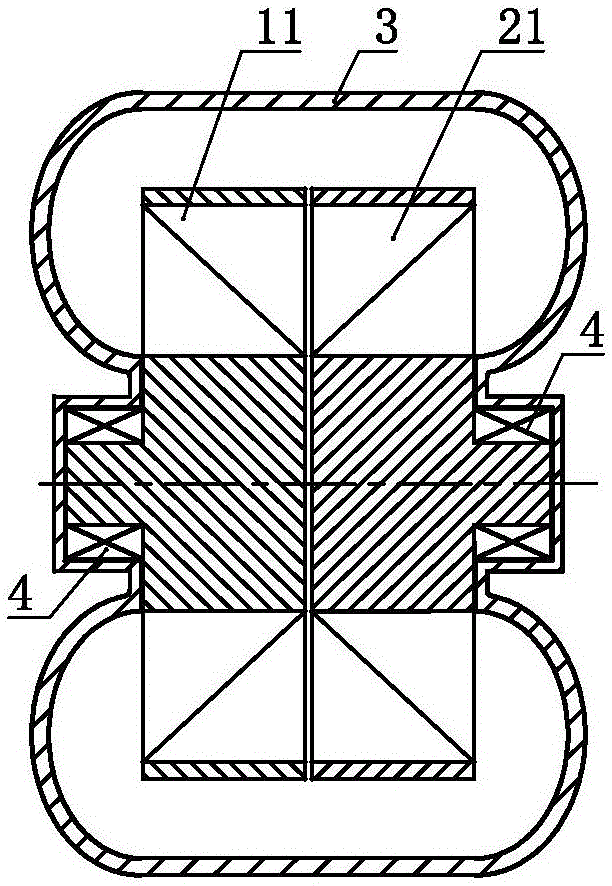

[0068] A fully enclosed fluid transmission mechanism, such as image 3 As shown, on the basis of Embodiment 2, the fully enclosed fluid transmission mechanism further includes a guide wheel 5 , and the guide wheel 5 is arranged in the sealed casing 3 .

[0069] As a changeable implementation, the changeable implementation of Example 2 of the present invention can further selectively make the fully enclosed fluid transmission mechanism further include a guide wheel 5, and the guide wheel 5 is arranged in the sealed casing within 3.

[0070] As a changeable implementation mode, in Embodiment 3 of the present invention, the clutch switching setting between the guide wheel 5 and the sealed housing 3 can also be selected selectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com