A Submerged Heat Exchange Tube Assembly with Subsection Heating

A technology of heat exchange tubes and components is applied in the field of heat exchange components of immersed heat exchangers, which can solve the problems of low heat exchange efficiency and low heat exchange efficiency, achieve convenient operation, improve heat exchange efficiency, and strengthen heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

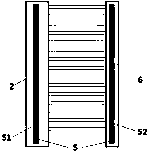

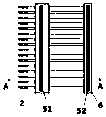

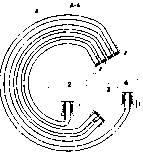

[0037] Figure 1-2 Schematic cutaway diagram showing submerged heat exchange components, such as figure 1 As shown, a submerged heat exchanger assembly includes a left tube box 2, a right tube box 6 and heat exchange tubes, the heat exchange tubes communicate with the left tube box 2 and the right tube box 6, and the electric heating device 5 is arranged on the left The tube box 2 and / or the right tube box 6; the left tube box 2, the right tube box 6 and the heat exchange tubes are filled with heating fluid, and the heating fluid is closed and flows in the left tube box 2, the right tube box 6 and the heat exchange tubes.

[0038] The electric heating device 5 is used for heating the internal fluid of the heat exchange assembly, and then the heated fluid is used to heat the fluid outside the heat exchange assembly.

[0039] Preferably, the electric heating device 5 is arranged in the left tube box 2 or the right tube box 6 .

[0040] Preferably, the heat exchange tubes are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com