Method for horizontal measurement of guided missile with laser tracker

A laser tracker and level measurement technology, applied in the field of measurement, can solve the problems of manual leveling, heavy measurement and calculation workload, and low efficiency, and achieve the effects of reducing level measurement equipment, reducing costs, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

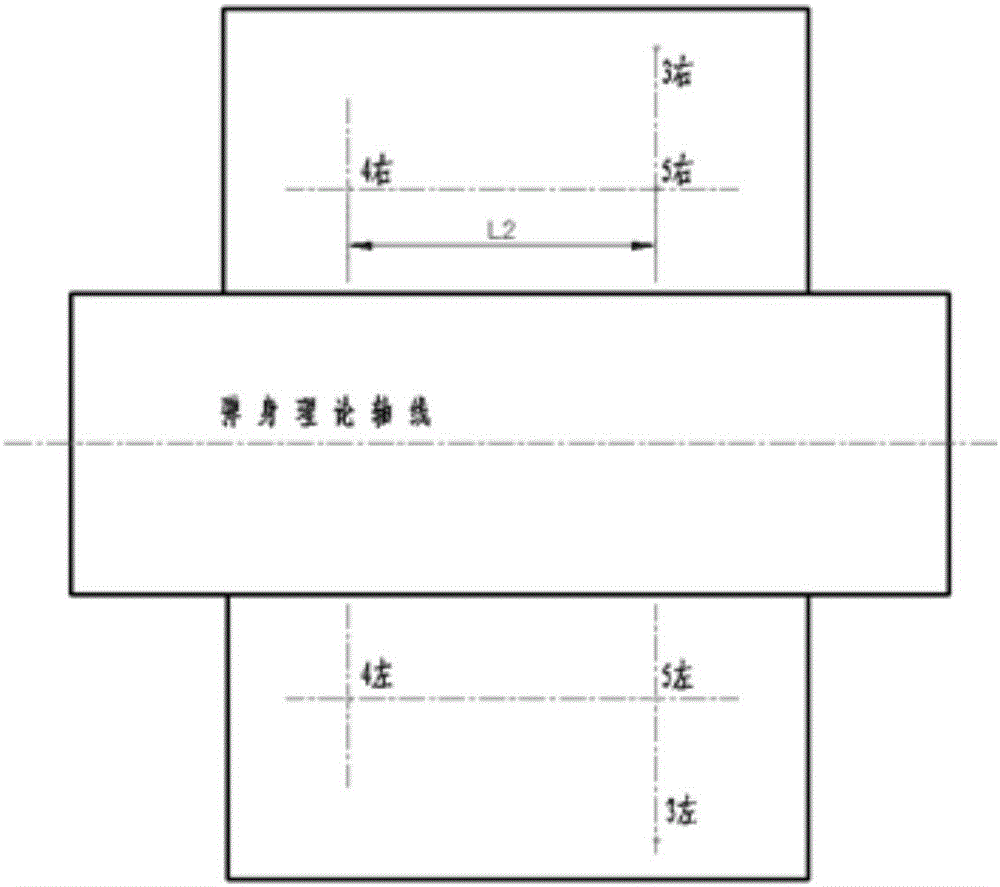

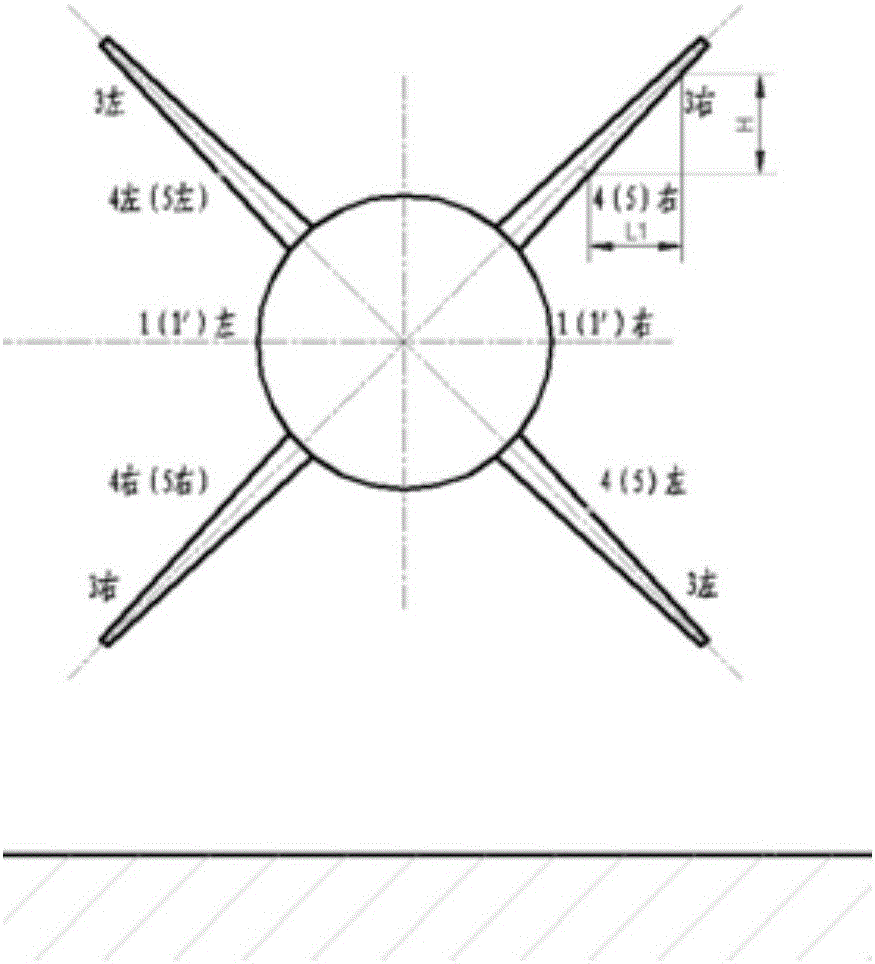

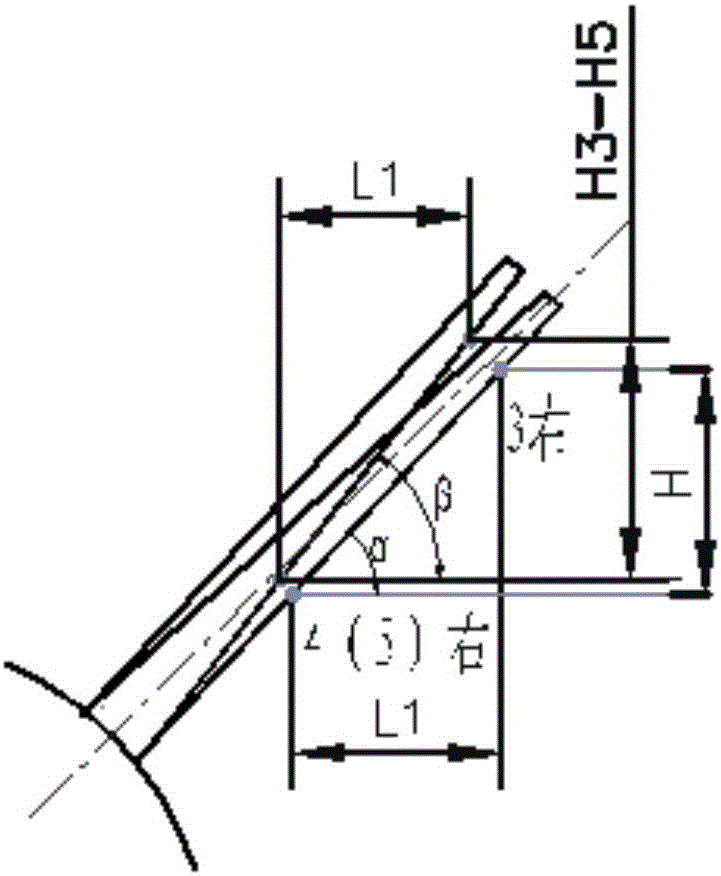

[0025] The laser tracker that the present invention design adopts carries out the method for missile level measurement, and the equipment used comprises laser tracker 1 (comprising console, pedestal and target ball) and front and rear universal support 2, wherein, laser tracker 1 is level The high-precision positioning equipment for measurement is used to establish a coordinate system and coordinate positioning of each horizontal measurement point, and is responsible for calculating the height difference of subsequent points relative to the virtual reference plane; the front and rear universal brackets 2 are used to support the missile during measurement , see attached image 3 .

[0026] The method for carrying out missile level measurement using a laser tracker of the present invention is used for level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com