Bottom plate mining failure zone segmental observation method

A technology of bottom plate mining and breaking belt, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of easy rupture, reduce the number of operating systems, etc. Steps, avoid high-pressure water filling and break easily, and the effect of high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention proposes a segmental observation method for the floor mining damage zone. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific embodiments.

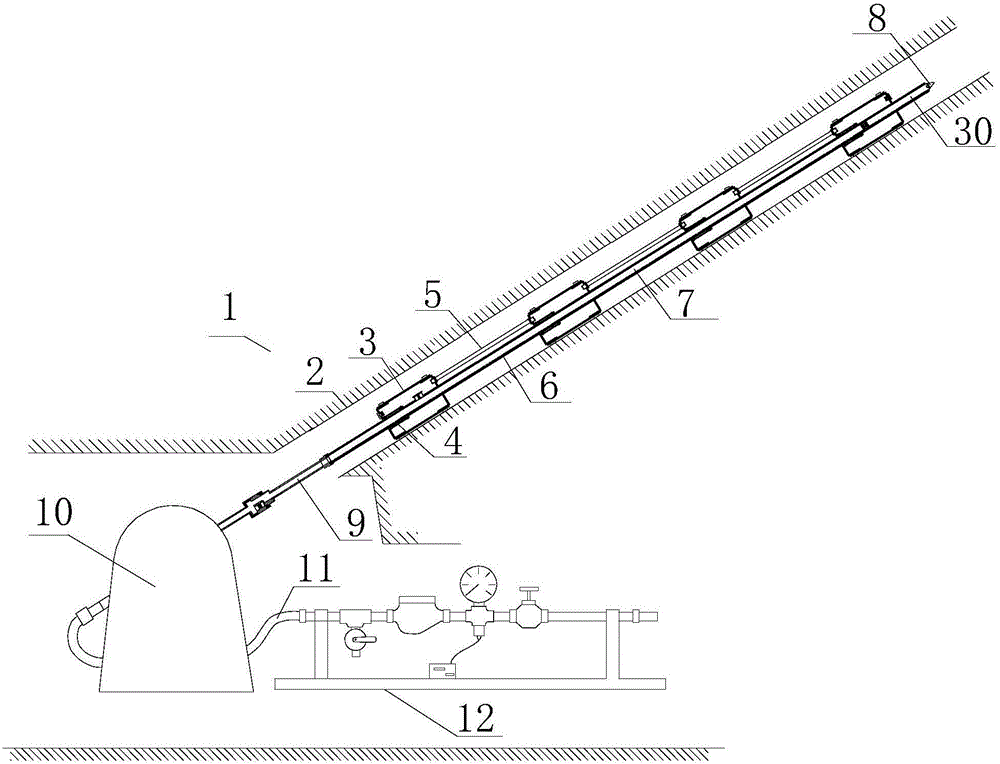

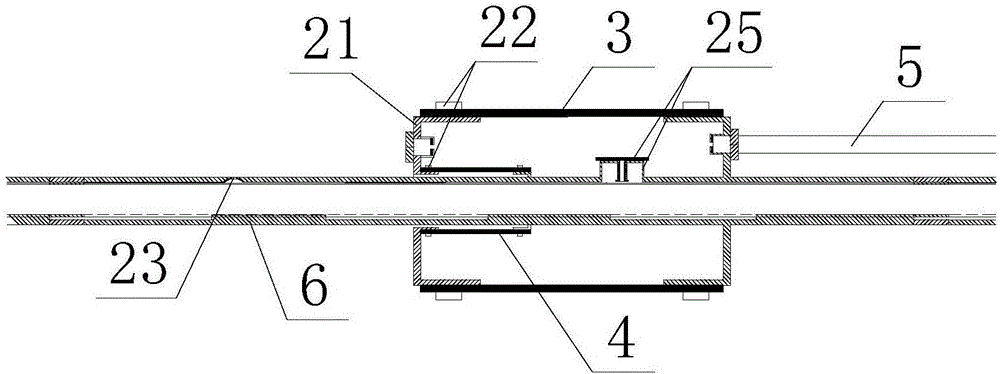

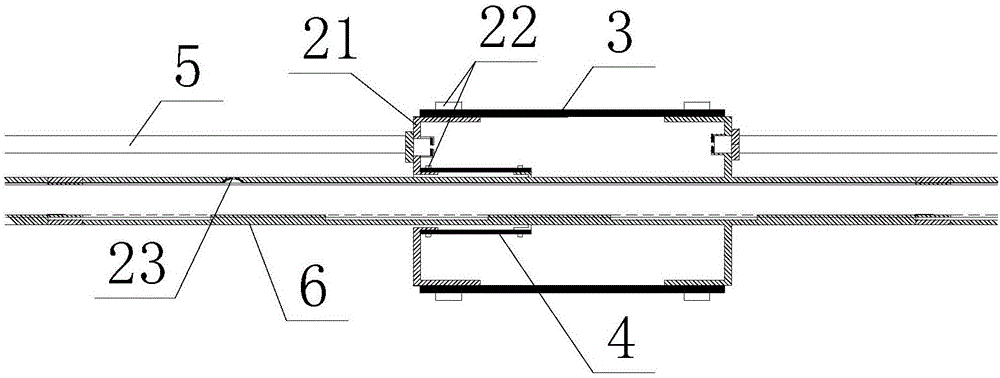

[0052] As shown in Figure 1, the observation system used in the sub-section observation method of the floor mining damage zone of the present invention includes a plugging system, a detection system, a pressure conversion system and a propulsion supply system.

[0053] detection system combination figure 1 , Figure 9 As shown, it includes a guide cone 8 and a detection inner tube. The detection inner tube includes a type I detection inner tube 31 and a type II detection inner tube 7 connected together in sequence, wherein the type I detection inner tube 31 has a section, and the type II detection inner tube The tube 7 can be set in several sections, the specific number is sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com