Railway axle modified KT figure acquiring method and damage tolerance design method

An acquisition method and axle technology, applied in railway vehicle testing and other directions, can solve the problems of not considering the inherent discontinuity of the matrix material and structural geometry, safety hazards, etc., to shorten the non-destructive detection cycle and ensure service reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0036] The method for obtaining the corrected KT diagram of the high-speed railway axle disclosed by the present invention comprises the following steps:

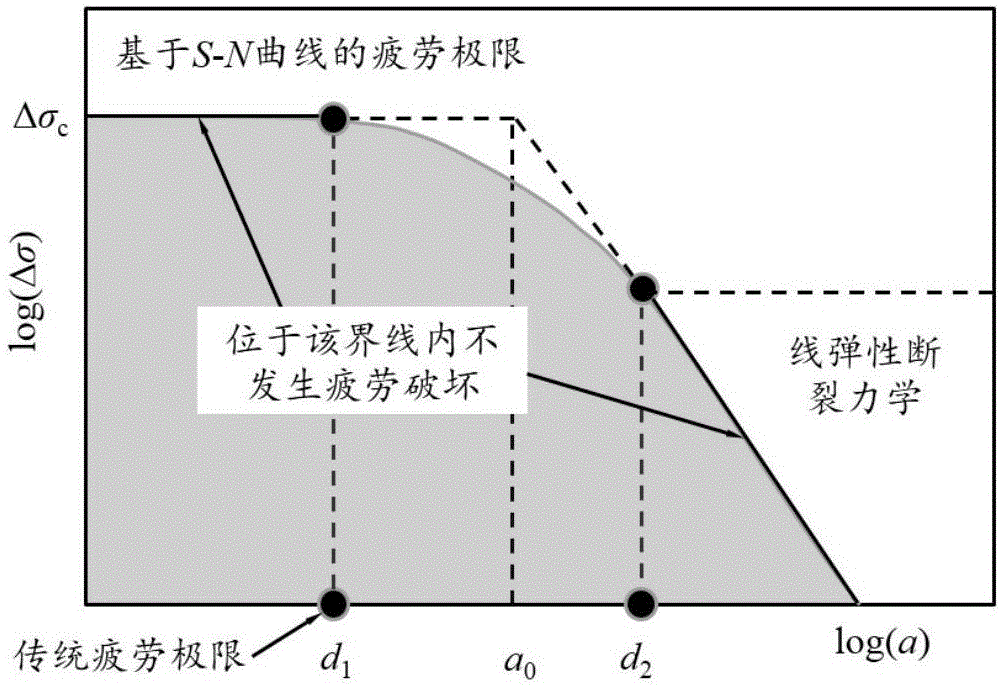

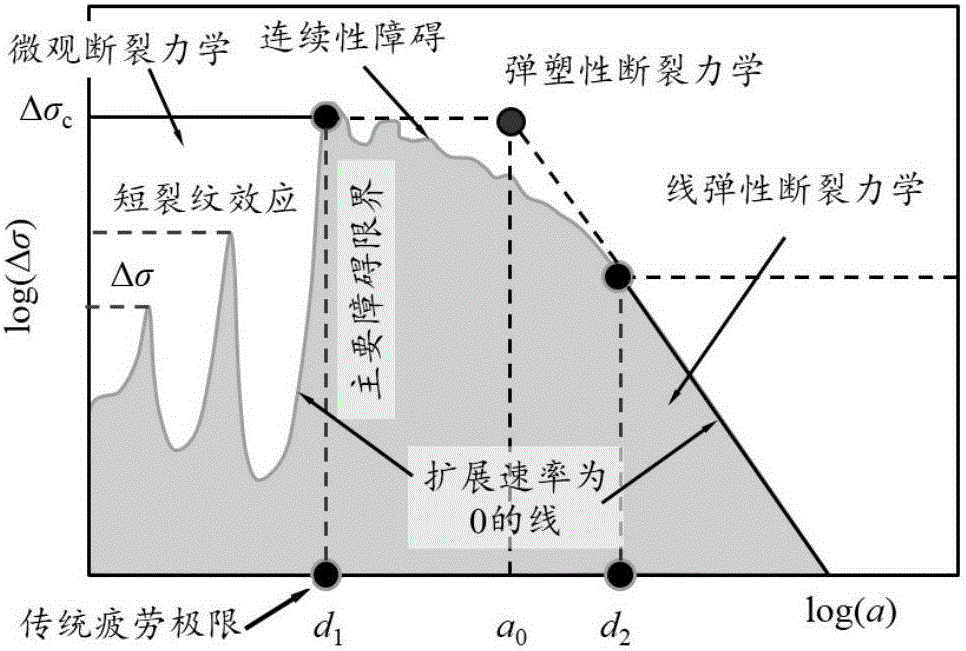

[0037] Step 1. Based on the nominal stress method, select at least 3 full-size axles for bench fatigue tests, and combine the European EA4T alloy steel and carbon steel induction hardened hollow axle design standards to obtain the fatigue limit σ c , put σ c The corresponding defect size is set to d 1 , d 1 = 10d, where d is the average grain size or microstructural barrier length;

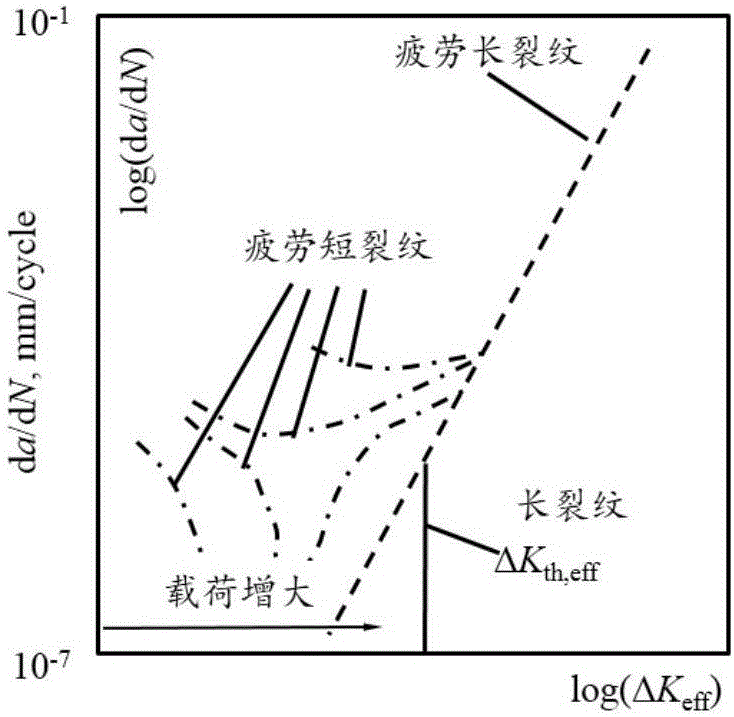

[0038] Step 2: Cut out semi-elliptical cracks perpendicular to the axis with a depth of 0.5-2 mm at the research site of i sampled axles by electric spark method, and then perform a rotating bending fatigue loading bench test on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com