Surface modified aramid fiber and preparation method thereof

A kind of aramid fiber, surface modification technology, applied in the direction of fiber type, fiber treatment, light/infrared/X-ray fiber treatment, etc., can solve the problem of limited bonding force between inorganic materials and organic fibers, poor heat resistance and oxidation resistance, Organic fiber photocatalytic degradation and other problems, to ensure service reliability, high heat resistance, improve tensile strength and work at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

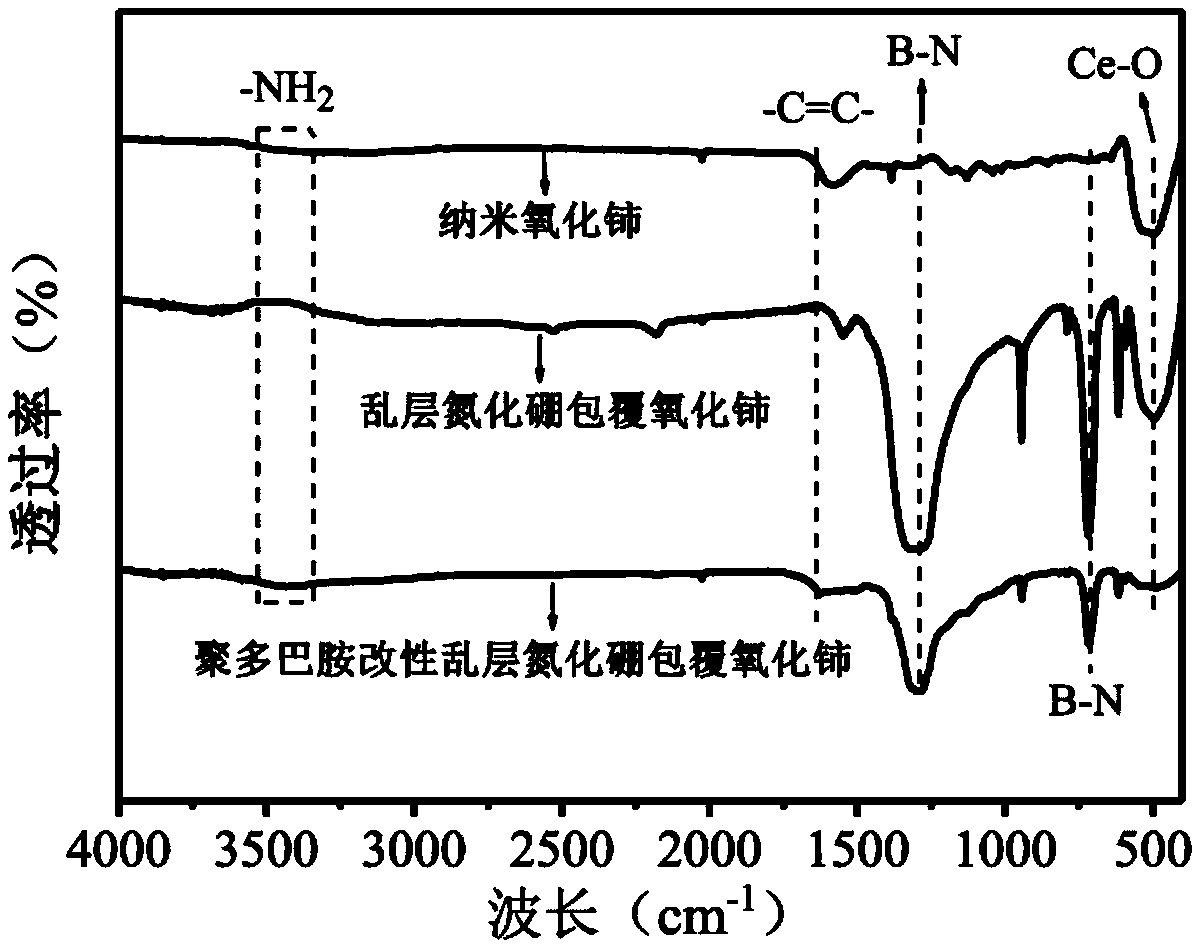

[0050] 1. Preparation of surface modified aramid fiber

[0051] (1) 1g of aramid fiber (Kevlar-49, diameter 12μm, density 1.45g / m 3 , produced by DuPont, USA) were immersed in acetone at 70°C, petroleum ether at 75°C, and deionized water at 115°C in turn, and kept for 3 hours respectively; then the fibers were taken out and dried in a vacuum oven at 80°C to obtain clean aramid fibers. is KF;

[0052] (2) Dissolve 10.5g of sodium hydroxide in 120mL of ethanol to prepare ethanol solution A of sodium hydroxide; immerse the clean aramid fiber KF obtained in step (1) in the above solution A, shake at 65°C React for 5h, after the reaction finishes, wash and dry to obtain aramid fibers with amino groups and carboxyl groups on the surface;

[0053] (3) Add 0.25g of aramid fibers with amino and carboxyl groups on the surface and 30mL of γ-glycidyl etheroxypropyltrimethoxysilane to 70mL of ethanol, and react at 70°C for 12h under a nitrogen atmosphere; after the reaction , take out t...

Embodiment 2

[0065] 1. Preparation of surface modified aramid fiber

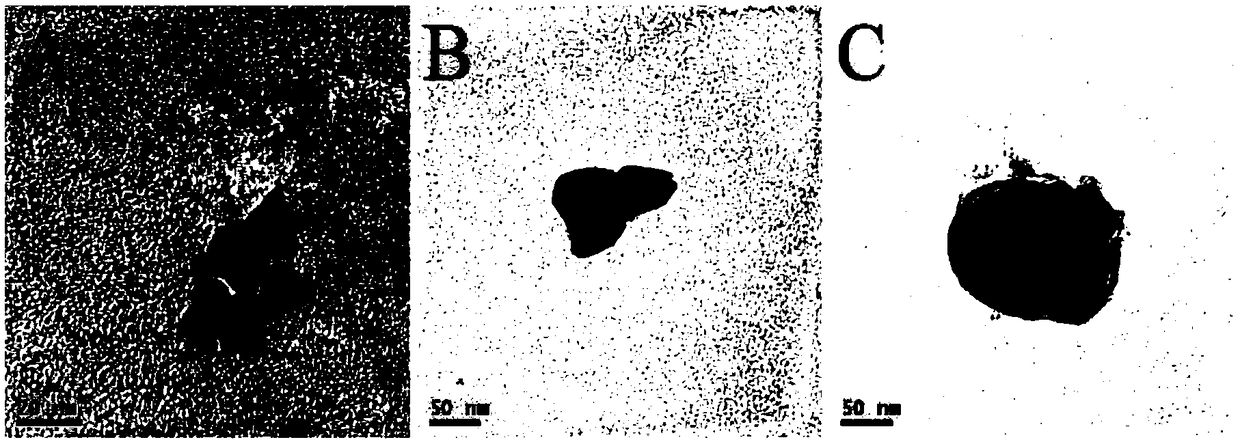

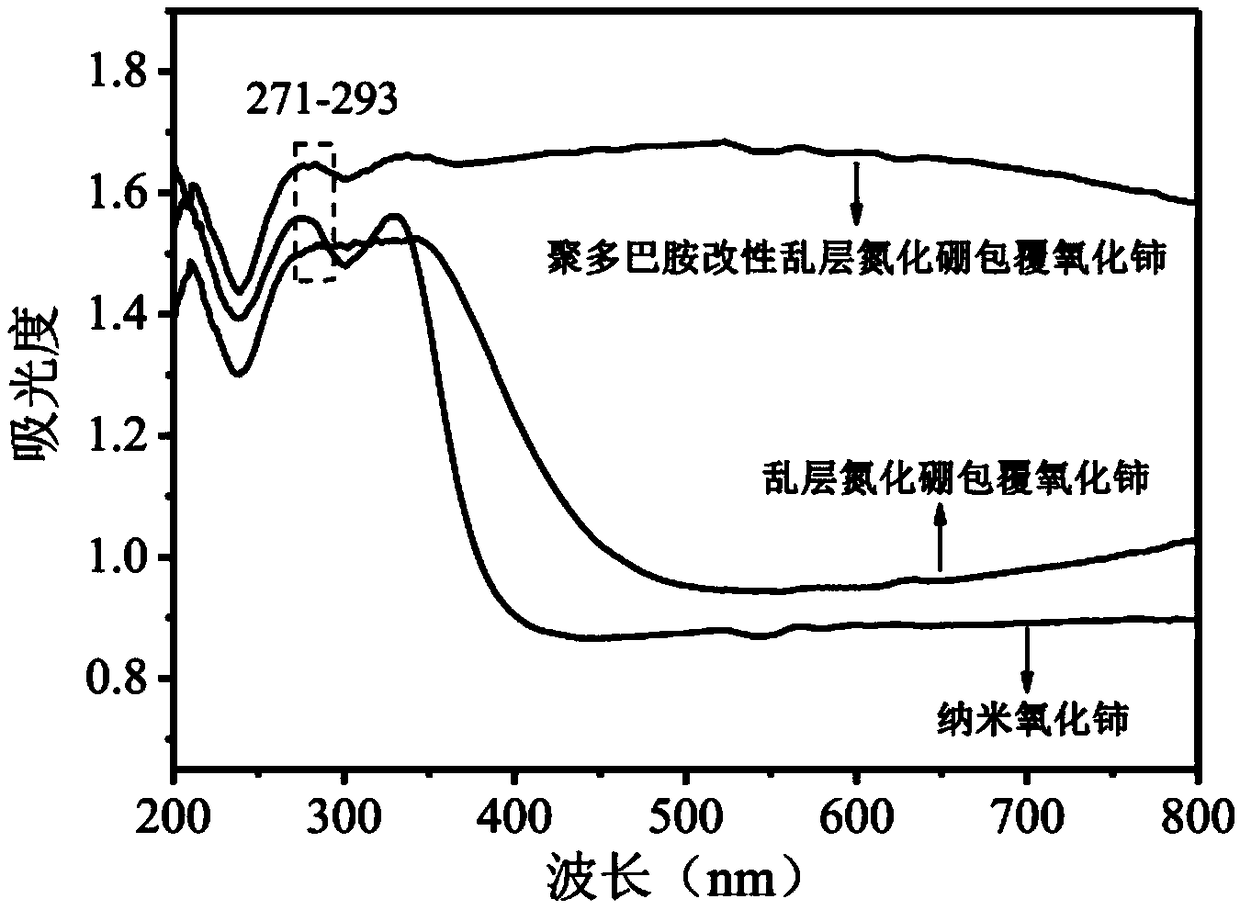

[0066] Disperse 0.5g of silicon-containing methoxy aramid fibers prepared in step (6) of Example 1, and 3.75g of polydopamine-modified turbostratic boron nitride-coated cerium oxide in an aqueous solution, and shake for 6 hours at a temperature of 60°C After the reaction, the fiber is taken out, washed and dried. Obtain surface-modified aramid fibers, denoted as T-KF2, its infrared spectrum, scanning electron microscope (SEM) photos, tensile properties and work-to-break refer to the attached Figure 5 , 6 and 7, surface contact angles and free energies are shown in Table 1.

[0067] 2. Ultraviolet irradiation of clean fiber and modified fiber

[0068] According to the same steps and conditions of embodiment 1, the aramid fiber T-KF2 that obtains in embodiment 2 is carried out the UV irradiation of 168h, obtains the 168h ultraviolet radiation fiber, is denoted as UV-T-KF2, its tensile properties and Work of fracture s...

Embodiment 3

[0077] 1. Preparation of surface modified aramid fiber

[0078] (1) 1g of aramid fiber (Kevlar-49, diameter 12μm, density 1.45g / m 3 , produced by DuPont, USA) were immersed in acetone at 70°C, petroleum ether at 75°C, and deionized water at 115°C in turn, and kept for 3 hours respectively; then the fibers were taken out and dried in a vacuum oven at 80°C to obtain clean aramid fibers. for KF.

[0079] (2) Dissolve 10.5g of sodium hydroxide in 120mL of ethanol to prepare ethanol solution A of sodium hydroxide; immerse the clean aramid fiber KF obtained in step (1) in the above solution A, shake at 65°C After reacting for 5 hours, after the reaction, washing and drying are carried out to obtain aramid fibers with amino groups and carboxyl groups on the surface.

[0080] (3) Add 0.25g of aramid fibers with amino and carboxyl groups on the surface and 30mL of γ-glycidyl etheroxypropyltrimethoxysilane to 70mL of ethanol, and react at 70°C for 12h under a nitrogen atmosphere; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com