Embedded touch screen and liquid crystal display apparatus

An embedded touch screen and touch screen technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve the problems of low light transmittance, high production cost, and thick modules, so as to achieve enhanced effects and reduce metal reflections. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

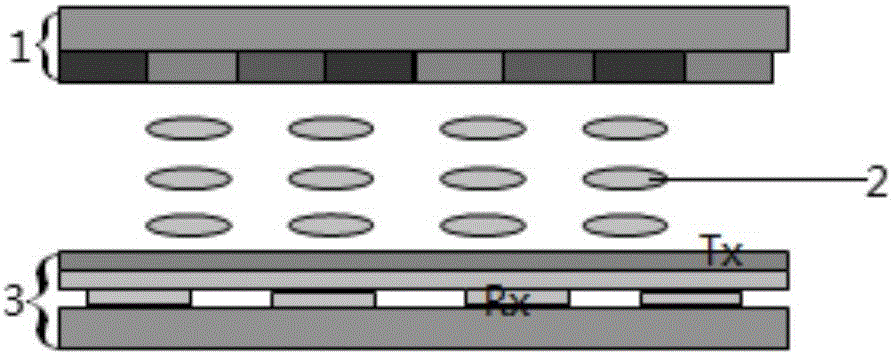

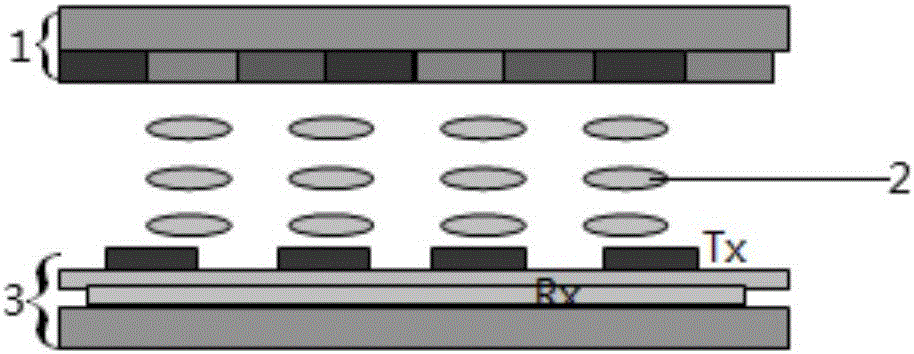

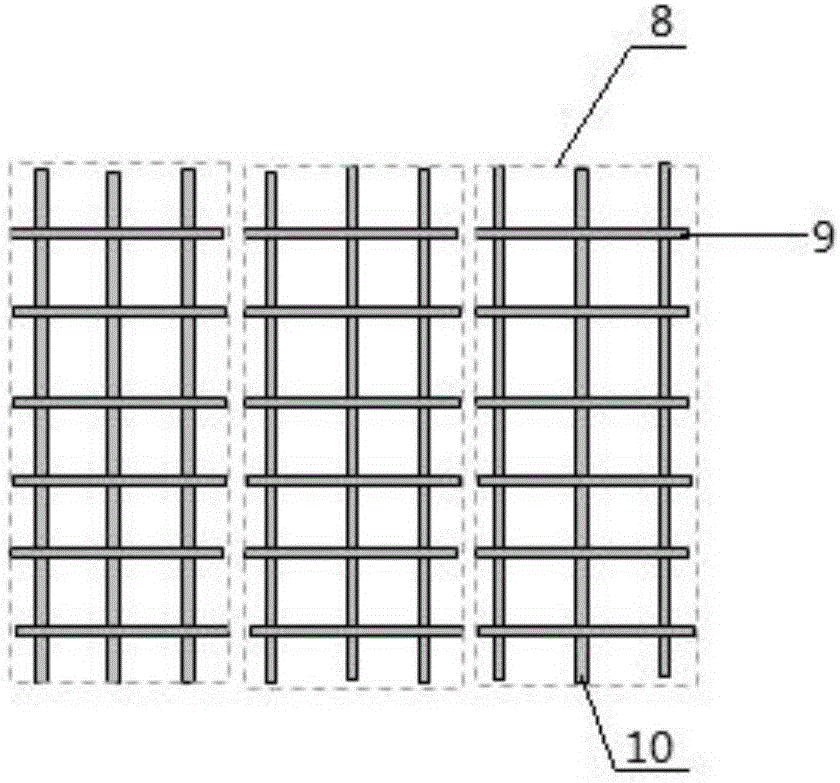

[0029] The embedded touch screen of the present invention includes an array substrate 3, and a plurality of horizontally arranged scanning lines 12 and a plurality of vertically arranged data lines 13 are formed on the surface of the array substrate 3, and the scanning lines 12 and the data lines 13 are arranged horizontally and vertically; the array The substrate 3 is sequentially prepared with a conductive light-shielding layer and an interlayer insulating layer (conductive light-shielding layer-interlayer insulating layer-scanning line metal substrate-interlayer insulating layer-data line metal layer-other layers) before preparing the scanning line metal layer, That is, the array substrate 3 is sequentially sputtered with a conductive light-shielding layer and an interlayer insulating layer under the metal layer of the scanning line; The sensing line 9 and a plurality of longitudinal sensing lines 10 distributed along the data line 13, the transverse sensing line 9 and the l...

Embodiment 2

[0035] The embedded touch screen of the present invention includes an array substrate 3, and a plurality of horizontally arranged scanning lines 12 and a plurality of vertically arranged data lines 13 are formed on the surface of the array substrate 3, and the scanning lines 12 and the data lines 13 are arranged horizontally and vertically; the array The substrate 3 is sequentially prepared with a conductive light-shielding layer and an interlayer insulating layer (conductive light-shielding layer-interlayer insulating layer-scanning line metal substrate-interlayer insulating layer-data line metal layer-other layers) before preparing the scanning line metal layer, That is, the array substrate 3 is sequentially sputtered with a conductive light-shielding layer and an interlayer insulating layer under the metal layer of the scanning line; The sensing line 9 and a plurality of longitudinal sensing lines 10 distributed along the data line 13, the transverse sensing line 9 and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com