Square battery reversing mechanism

A technology of reversing mechanism and square battery, which is applied in the direction of primary battery, battery assembly machine, equipment for manufacturing primary battery, etc., to achieve the effect of ensuring work efficiency and automation, reliable work, and compact overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

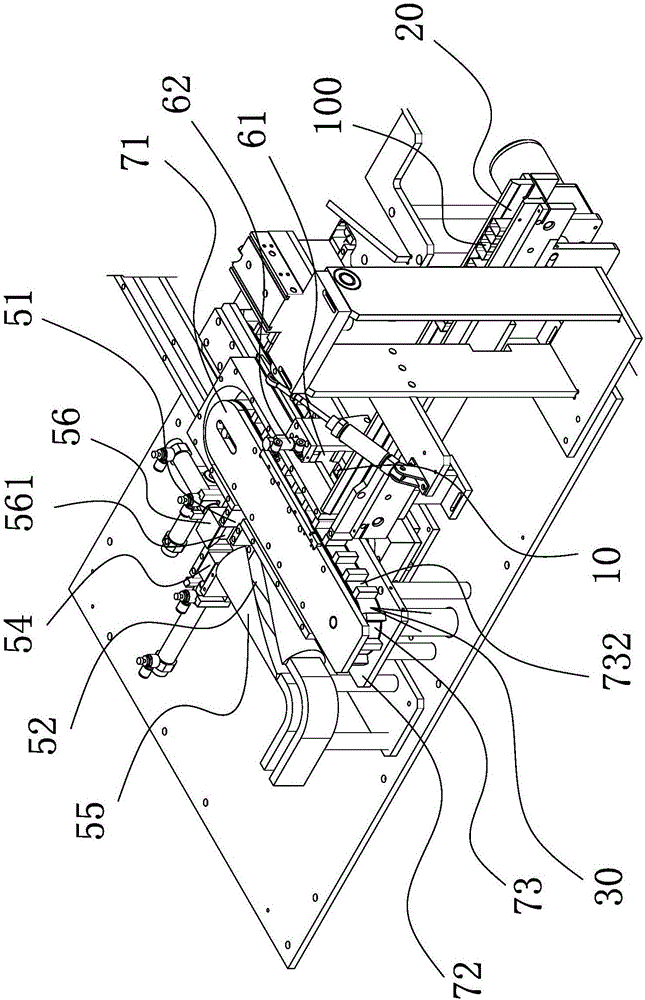

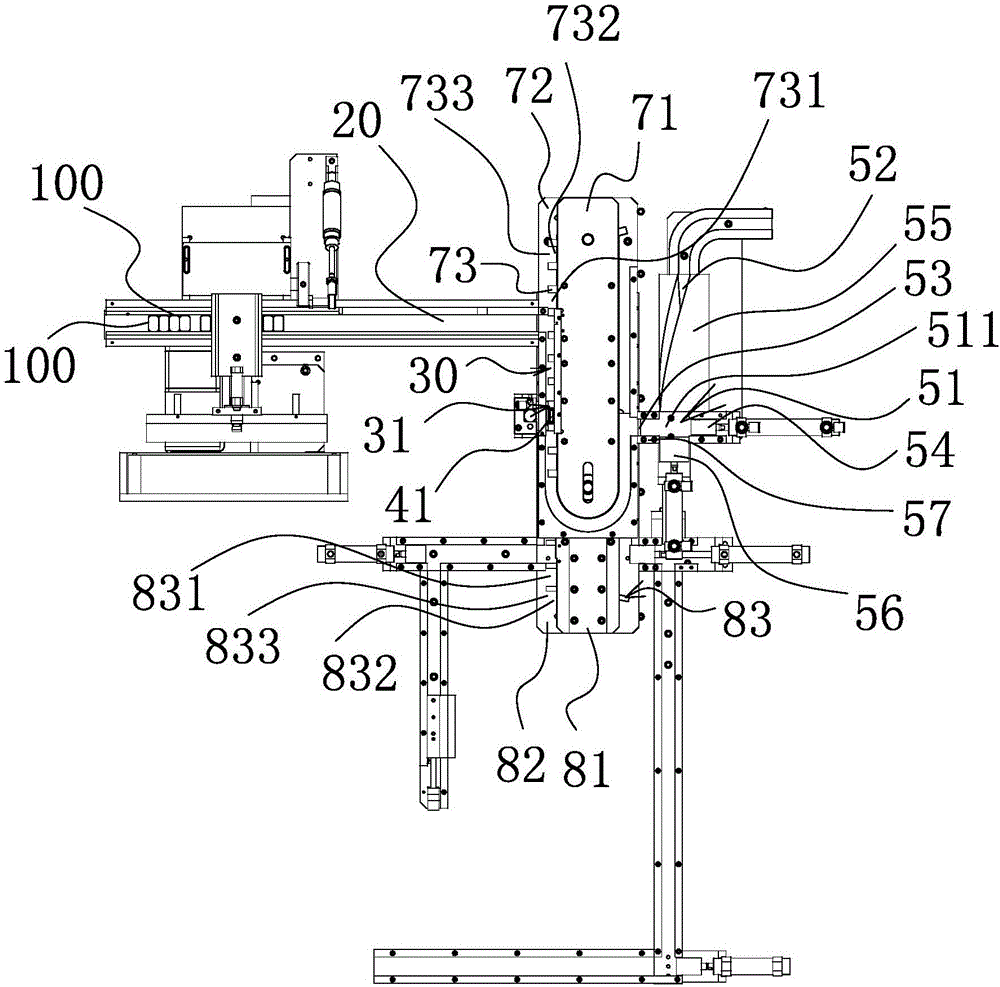

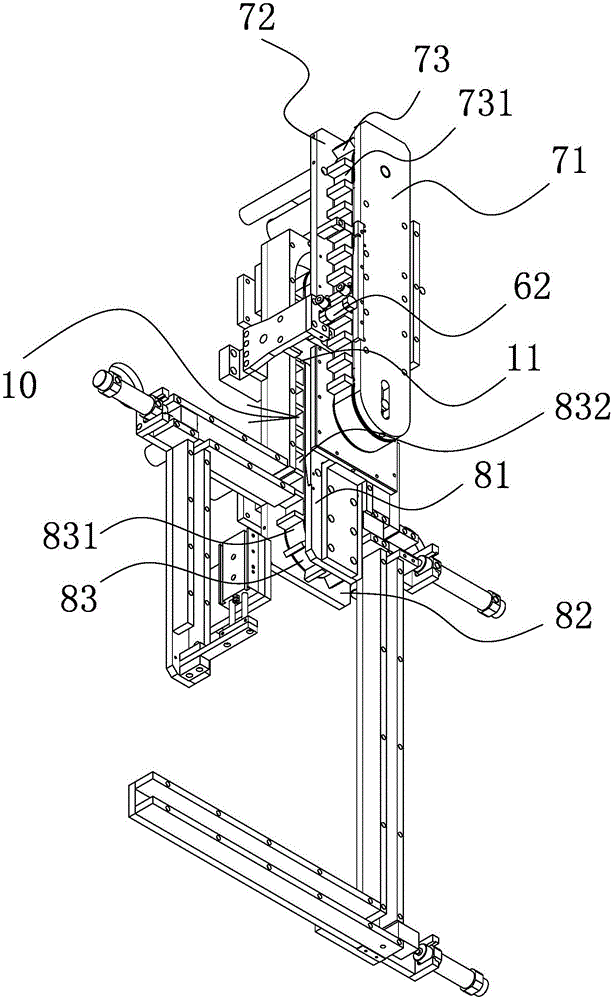

[0037] The following are specific embodiments of the present invention combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0038] The invention protects a square battery reversing mechanism, which receives a mold sleeve with multiple batteries and an empty square battery steel shell, and presses the battery (a battery pack composed of multiple batteries) in the mold sleeve into the battery Inside the steel shell, the steel shell with the battery installed is turned upside down to facilitate subsequent spot welding of the unwelded end of the square battery. The overall working process is highly automated, and the production efficiency is high, and it is suitable for high automation requirements. Production Environment.

[0039] Combine below Figure 1 to Figure 5 The technical solution provided by the present invention is described in more detail.

[0040] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com