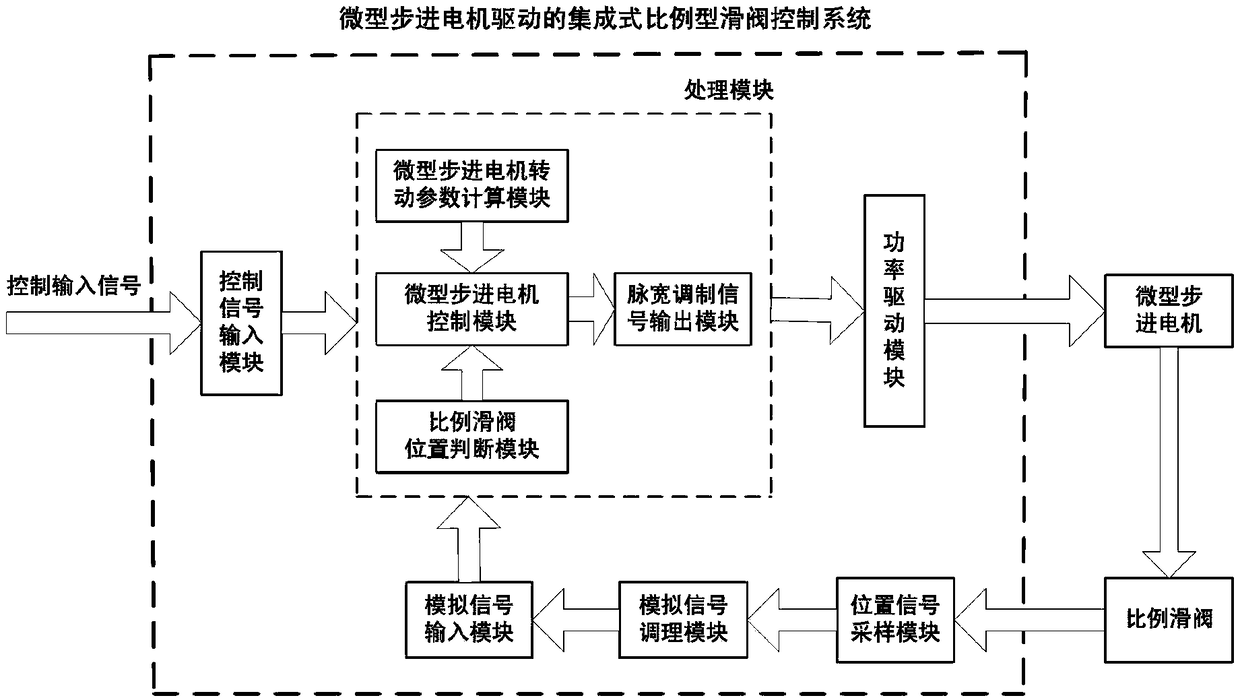

Control system and control method of integrated proportional slide valve driven by micro stepping motor

A stepper motor, integrated technology, used in control systems, motor generator control, valve operation/release devices, etc., can solve problems such as control failure, change of input and output ratio relationship, spool stuck, etc. Achieve the effect of improving reliability, realizing accurate judgment, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

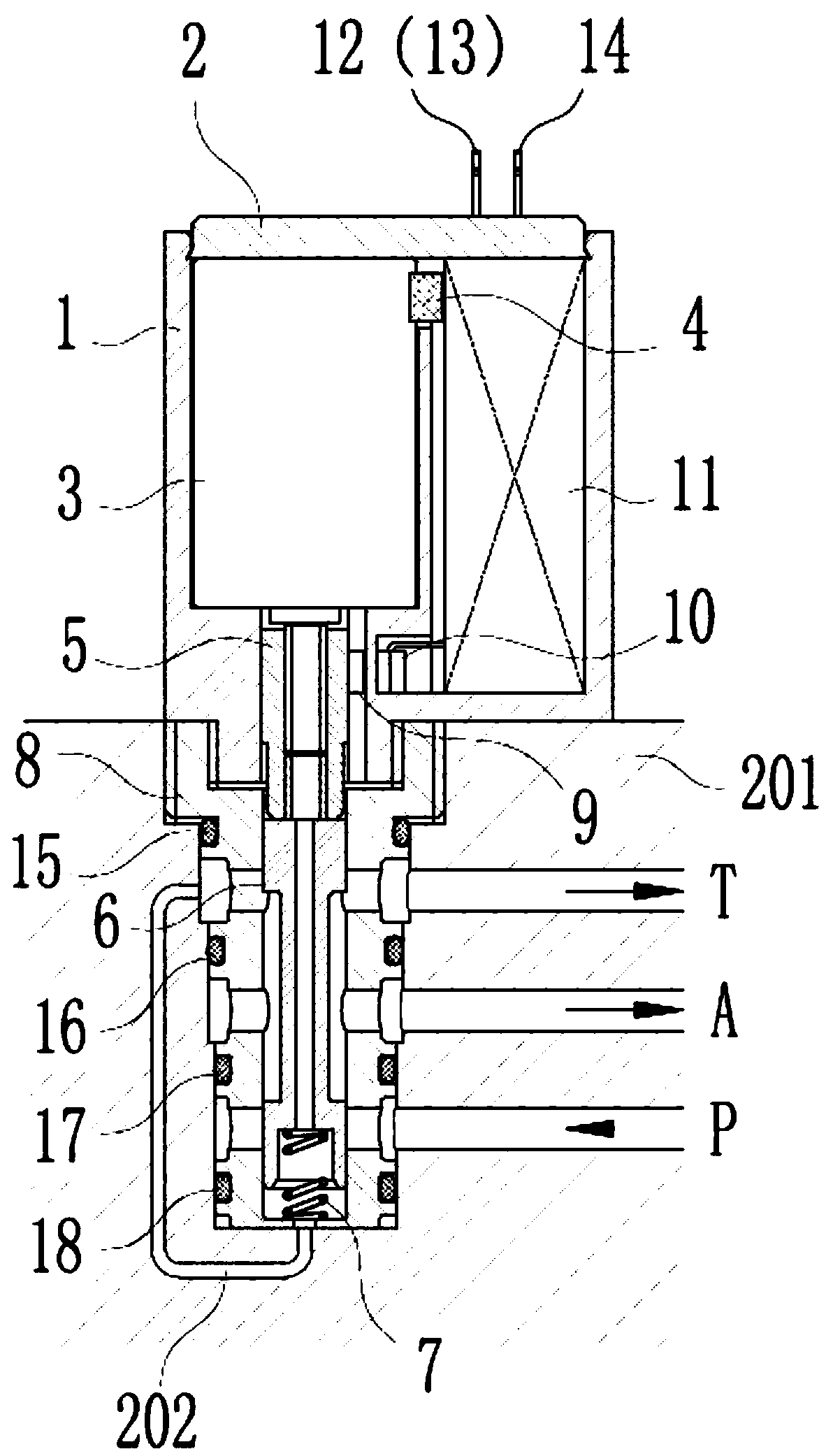

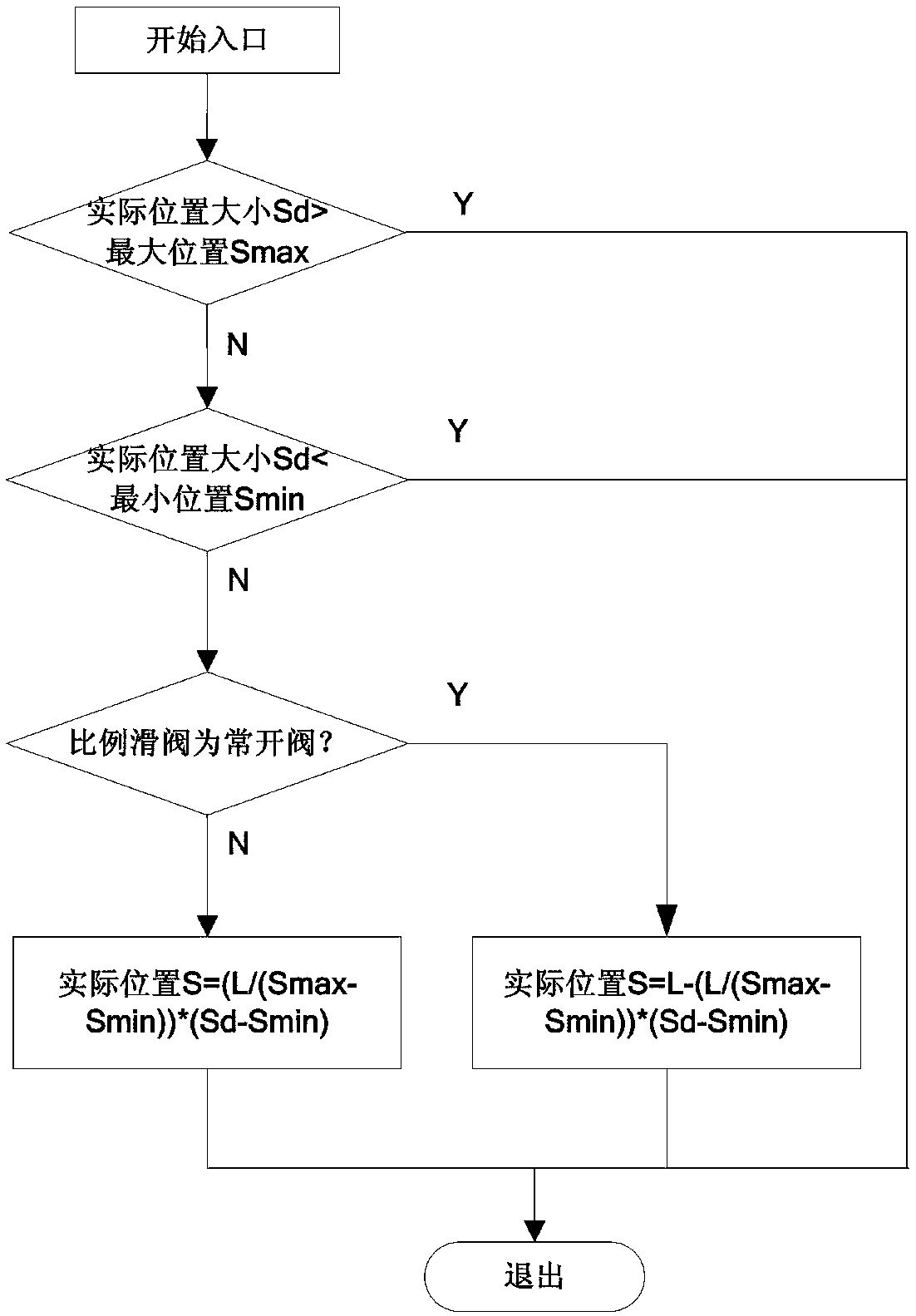

[0117] Embodiment: Take a certain type of micro stepper motor and proportional slide valve type as an example, combine Figure 1 to Figure 4 , and describe the proportional control process of the integrated proportional spool valve as follows:

[0118] This type of miniature stepping motor is a two-phase four-wire DC stepping motor with a rated speed of 4000 rpm, a maximum speed of 6000 rpm, a rated operating frequency of 1000HZ, a maximum operating frequency of 2000HZ, and a step angle AM of 0.18 degrees / step; the output reduction ratio of the micro stepper motor is 1:1; the pitch T is 0.25 mm; the maximum opening L of the fluid channel controlled by the slide valve is 1 mm; the integrated proportional slide valve is a normally closed valve.

[0119] The proportional control process of the integrated proportional spool valve includes the following 6 processes:

[0120] (1) Control input signal acquisition

[0121] Select the external control input signal as the parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com