Novel agricultural machinery engine support

An engine bracket and agricultural machinery technology, applied in the field of agricultural machinery, can solve the problems of complex installation structure, difficult processing, difficult layout, etc., and achieve the effects of convenient processing and installation, easy layout and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

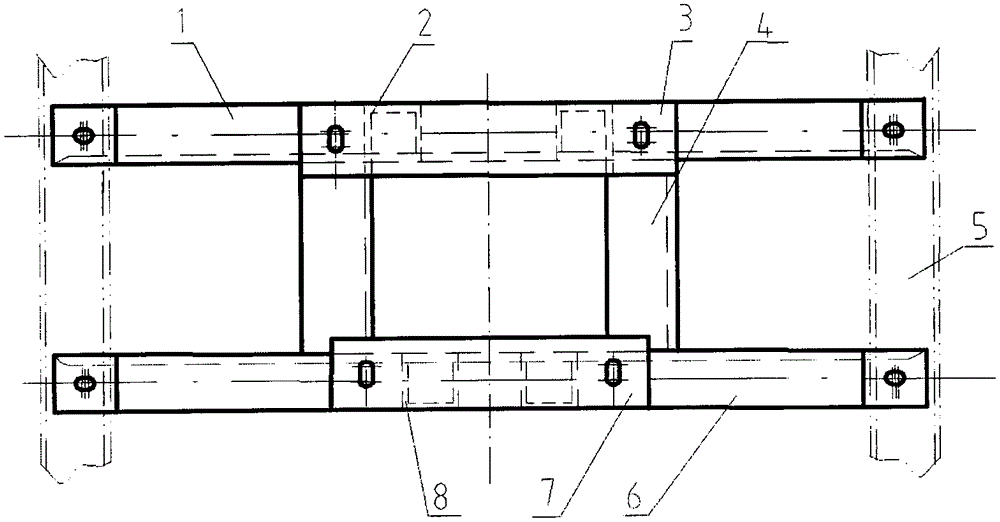

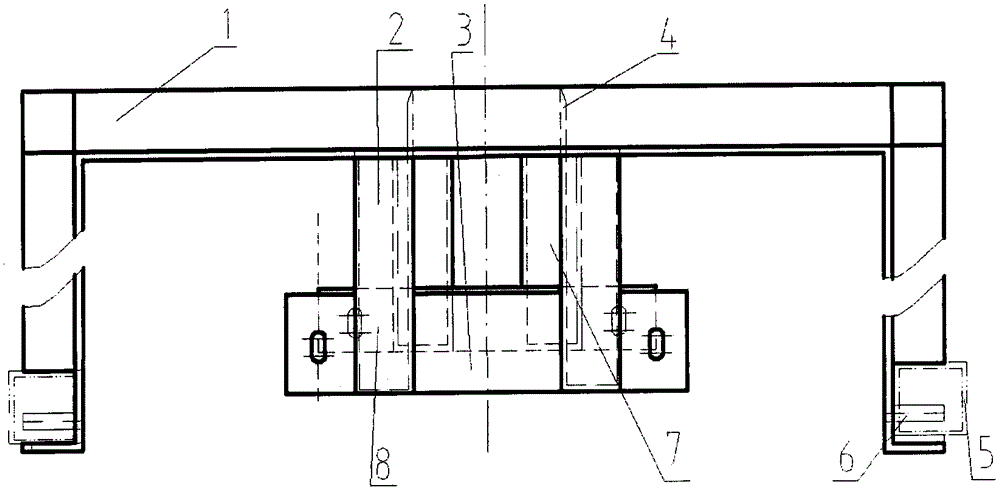

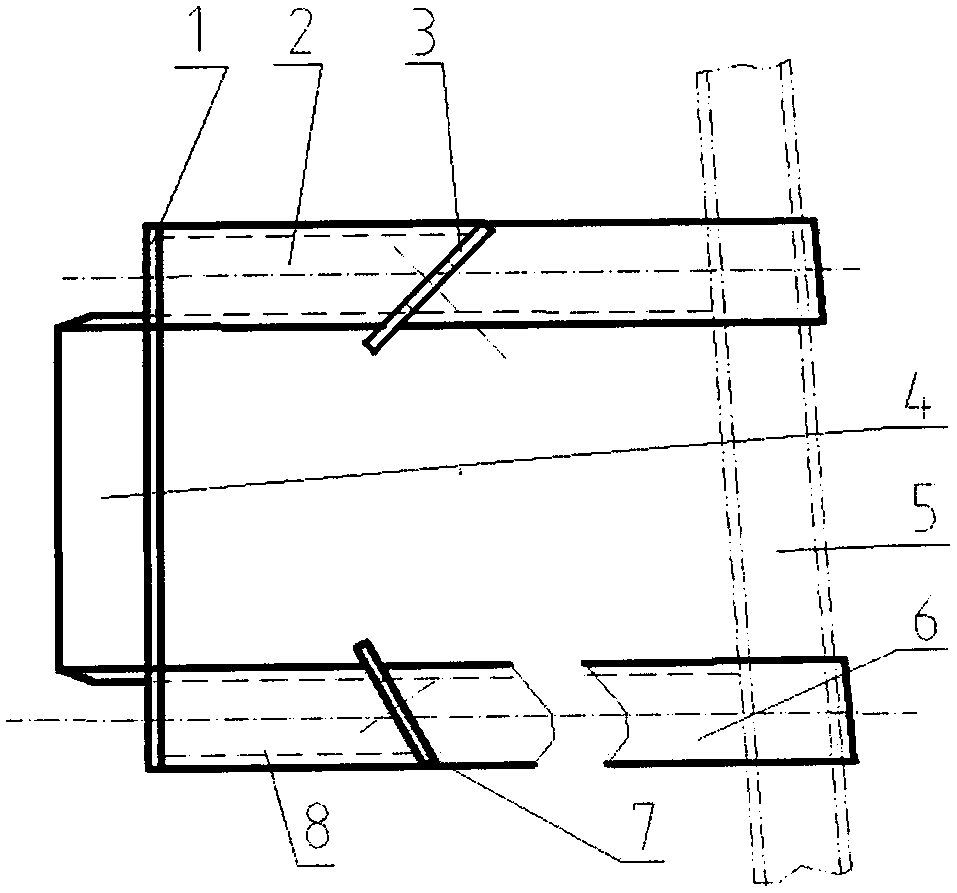

[0015] A new type of agricultural machinery engine bracket, composed of front support angle steel 1, front fixed rectangular steel 2, engine fixed front support plate 3, rear support angle steel 6, engine fixed rear support plate 7, rear fixed rectangular steel 8, front support angle steel 1 , the rear support angle steel 6 is only welded to the vehicle frame 5 respectively, the front and rear support angle steels 1 and 6 are welded to the reinforcement angle steel 4, and at the same time, a front fixed rectangular steel 2 is welded and fixed on the front support angle steel 1 on the left and right, and a rear fixed rectangular steel is welded on the left and right. Steel 8 is welded and fixed on the rear support angle steel 6, the engine fixed front support plate 3, the engine fixed rear support plate 7 are respectively welded and connected with the front fixed rectangular steel 2 and the rear fixed rectangular steel 8, and the engine is fixed by the engine. Fixing back suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com