Sock shoes and production process thereof

A technology for socks and shoe uppers, applied in the field of socks and shoes and their production processes, can solve the problems of poor elasticity of shoe uppers, soiled socks, easy to have peculiar smell, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

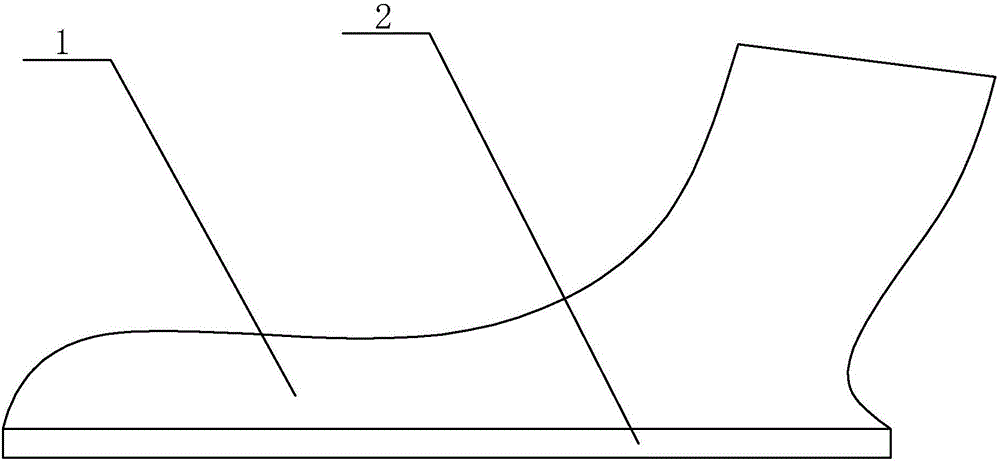

[0031] Embodiment 1: a kind of sock shoe, comprises vamp 1, and the shape of described vamp 1 is consistent with the curve shape of human foot, and the bottom of described vamp 1 is provided with sole 2, and described vamp 1 is cotton yarn, synthetic One or more than one of the fiber textile materials is a basic yarn and a sock is knitted by a hosiery knitting machine by adding hot-melt yarn.

[0032] The production technology of this socks footwear, comprises the steps:

[0033] (1) One or more than one of cotton yarn, synthetic fiber and other textile materials as the basic yarn, plus thermal fuse, is knitted by a hosiery machine to form the shoe upper 1;

[0034] (2) Put the vamp 1 on the shoe last, put it into the setting machine for heat setting and heating to make the thermal fuse shrink, the temperature is: 80-150 °C; cool down after heat setting;

[0035] (3), the vamp 1 is placed on the sole mold, and the sole material is injected into the sole mold by an injection m...

Embodiment 2

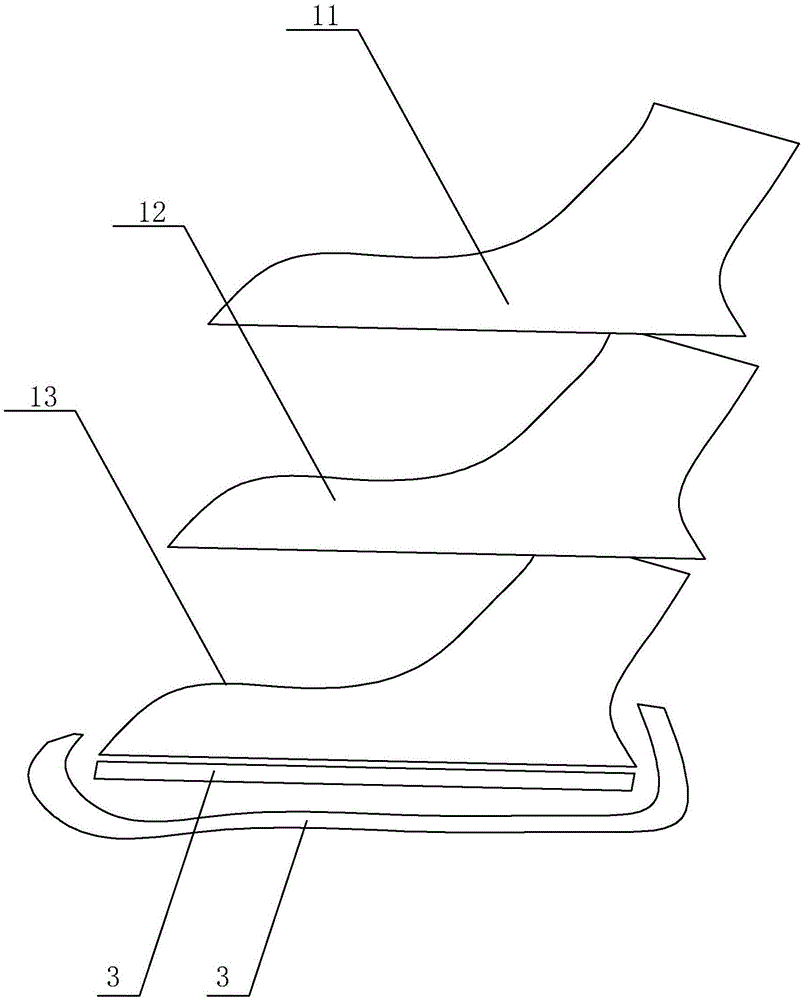

[0036] Embodiment 2: In order to make the socks waterproof, the vamp 1 includes an outer layer of socks 11, a waterproof membrane 12, and an inner layer of socks 13 from the inside to the outside, and the outer layer of socks 11, the waterproof membrane 12, and the inner layer of socks 13 bonded together.

[0037] The production technology of this kind socks footwear, comprises the steps:

[0038] (1) Outer layer socks 11 and inner layer socks 13 are woven by a hosiery knitting machine with one or more than one type of cotton yarn and synthetic fiber textile materials as basic yarns;

[0039] (2), put the outer socks 11 on the shoe tree, put them into the shaping machine for heat setting and heating to make the thermal fuse shrink, the temperature is: 80-150°C; cool down after heat setting;

[0040] (3), put the finished outer layer socks 11 on the waterproof membrane 12 and the inner layer socks 13, wherein the waterproof membrane 12 is placed between the outer layer socks 1...

Embodiment 3

[0042] Embodiment 3: In order for the socks and shoes to have the anti-puncture function, the bottom of the vamp 1 is also provided with an anti-puncture layer 3, and the anti-puncture layer 3 is fixed on the bottom of the vamp 1 through the sole 2.

[0043] The production technology of this socks footwear, comprises the steps:

[0044] (1) Outer layer socks 11 and inner layer socks 13 are woven by a hosiery knitting machine with one or more than one type of basic yarns in textile materials such as cotton yarn and synthetic fiber;

[0045] (2), put the outer socks 11 on the shoe tree, put them into the shaping machine for heat setting and heating to make the thermal fuse shrink, the temperature is: 80-150°C; cool down after heat setting;

[0046] (3), put the finished outer layer socks 11 on the waterproof membrane 12 and the inner layer socks 13, wherein the waterproof membrane 12 is placed between the outer layer socks 11 and the inner layer socks 13, and put it on the shoe la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com