Method and apparatus for f toluene oxidation tail gas treatment

A technology for oxidizing tail gas and toluene. It is applied in chemical instruments and methods, separation methods, and dispersed particle separation. It can solve the problems of inability to guarantee the recovery rate of aromatic hydrocarbons, large steam consumption, and reduced adsorption capacity of activated carbon, so as to ensure safe long-term operation. , the effect of reducing costs and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

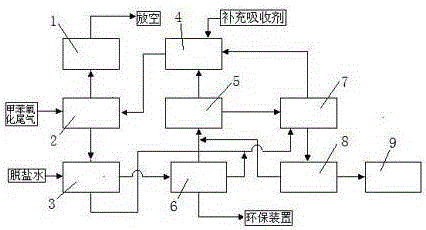

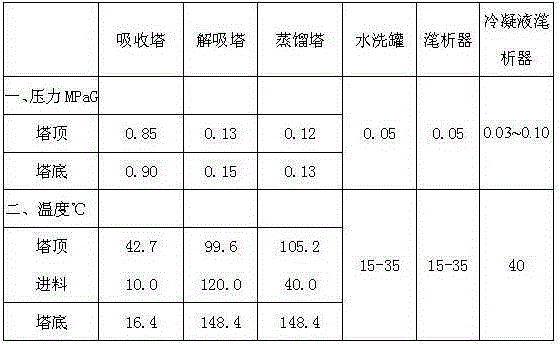

[0015] The device of toluene oxidation tail gas treatment of the present invention is as figure 1 As shown, it includes an adsorber 1, an absorption tower 2, a desorption tower 5, a washing tank 3, a decanter 6, an absorbent storage tank 4, a condensate decanter 7, a distillation tower 8 and a venting system connection. The absorption tower is a two-stage packed tower, and the packing in the packed tower is M250.Y packing. The desorption tower is a two-section packed tower, the lower section is the rectification section of the desorption tower, and the upper section is the stripping section of the desorption tower. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap