Automatic wood coloring device

A technology of wood and positioning device, which is applied in the direction of device and coating for coating liquid on the surface to achieve the effect of liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

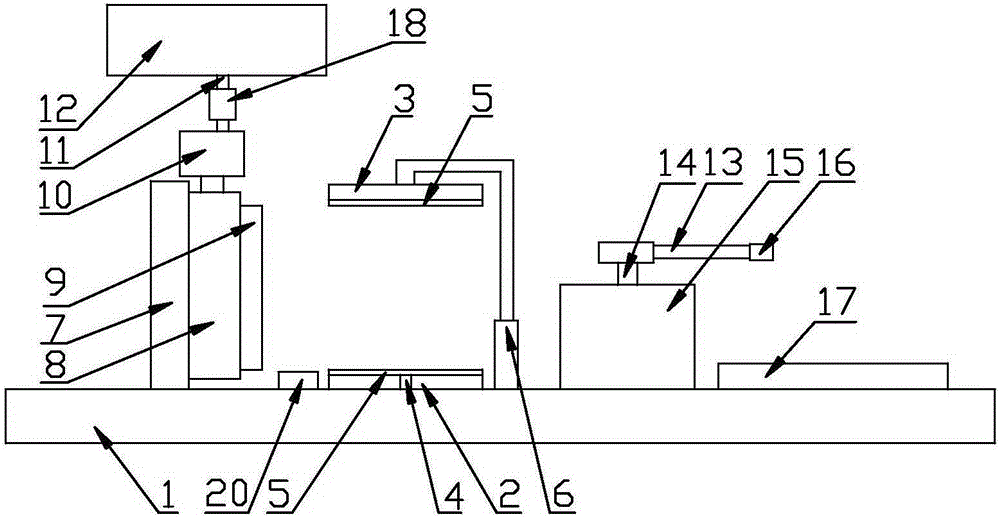

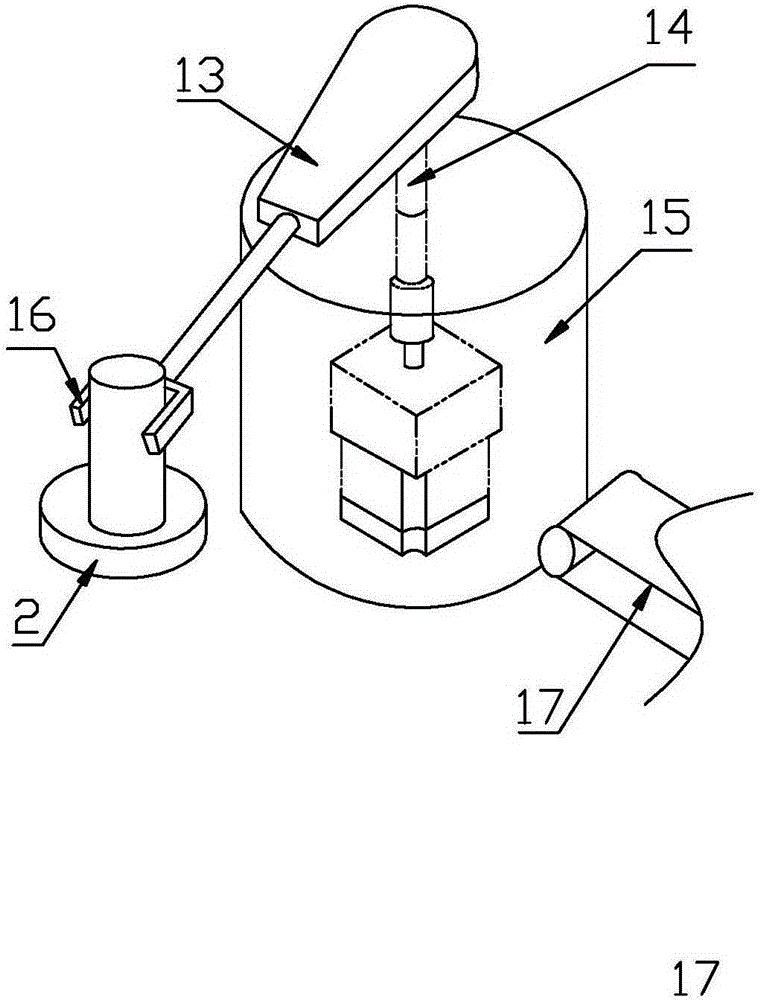

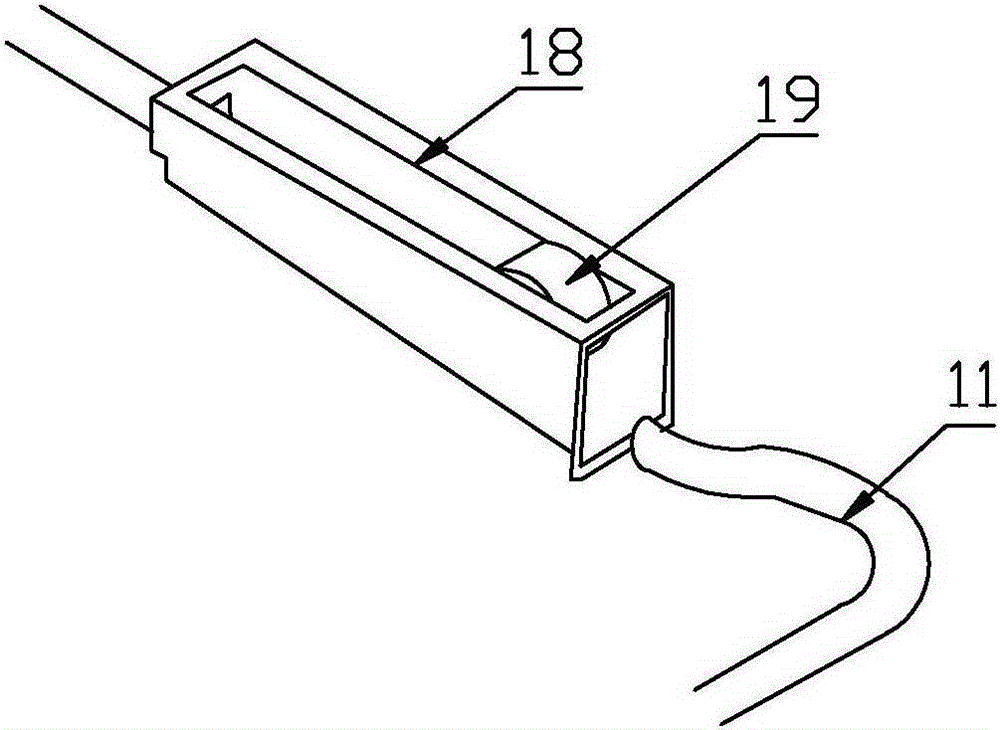

[0024] like Figure 1-3 As shown, an automatic wood coloring device includes a workbench 1, a positioning device and a coloring device are arranged on the workbench, the positioning device includes a base 2 and a top seat 3, and the base 2 is fixed by the center The connected rotating shaft 4 is hinged on the top surface of the workbench 1, and the top seat 3 is hinged to the top seat by the elevating rod 6, and a suction cup 5 is fixed on the top surface of the base 2 and the bottom surface of the top seat 3. The coloring device includes a fixed frame 7 and a coloring brush 8, the fixed frame 7 is vertically arranged on the workbench 1, and the fixed frame 7 is located on the left side of the positioning device, and the right end surface of the fixed frame 7 is fixed connected with a coloring brush 8, the coloring brush 8 is a hollow structure, the right end face of the coloring brush 8 is plugged with a brush pen 9, the top of the coloring brush 8 is connected with a color b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com