Radial-axial bi-directional asynchronous package-type bionic corn husker

A wrapping and peeling machine technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of difficult cutting, collision damage, high power consumption of peeling, etc., to increase the contact area, reduce extrusion damage, improve The effect of peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

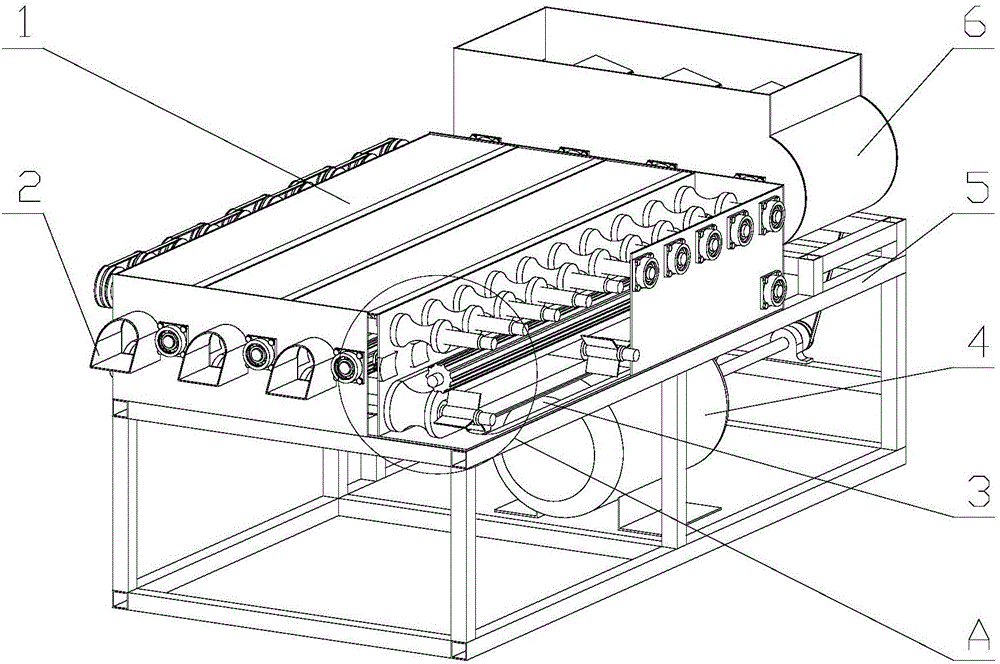

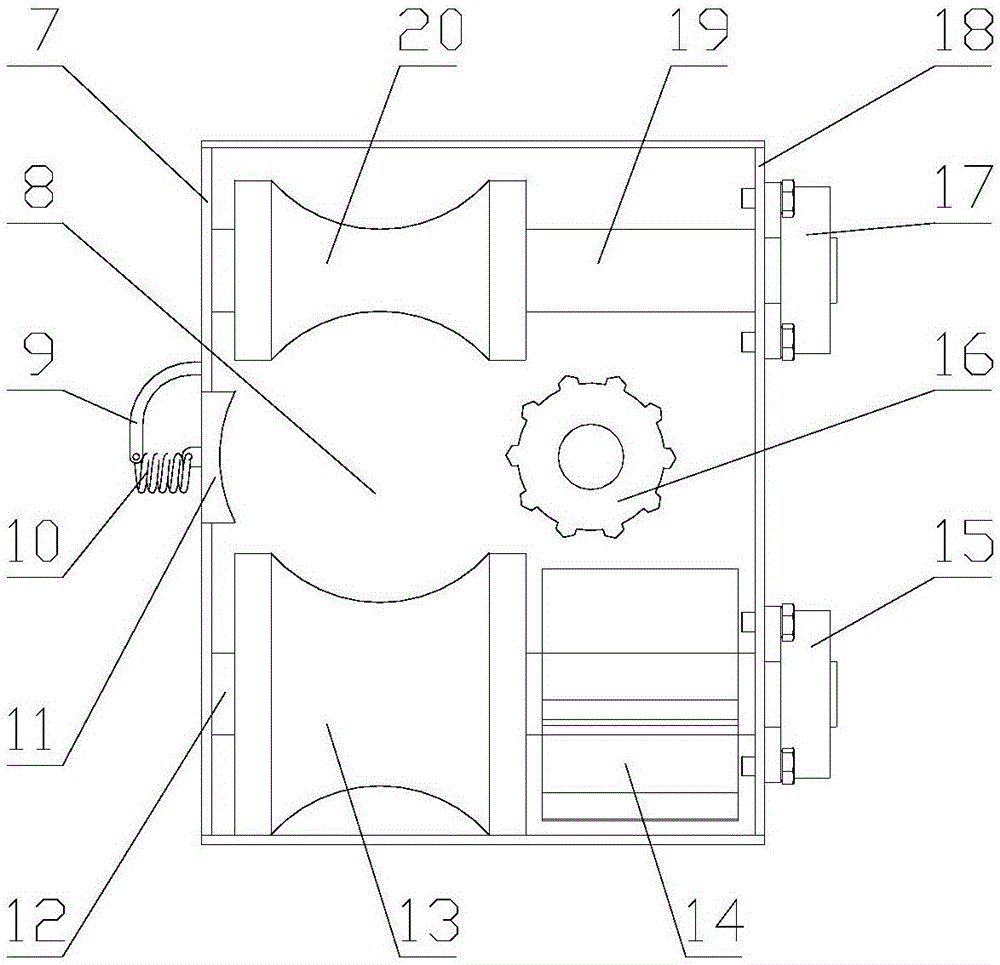

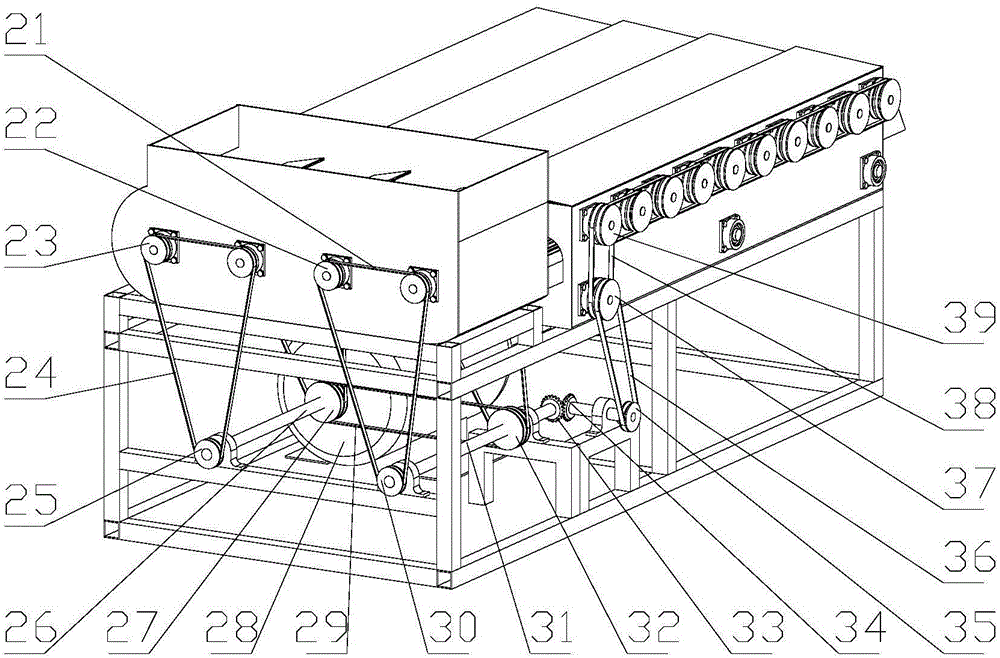

[0019] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5Shown, the present invention comprises peeling mechanism 1, transmission mechanism 4, frame 5 and feeding mechanism 6, and peeling mechanism 1 is fixed on the top front of frame 5, and feeding mechanism 6 is fixed on the top rear of frame 5; Mechanism 1 includes discharge port 2, leaf discharge port 3, feeding port 41, inner plate 7, peeling space 8, bow frame 9, spring 10, variable profiling pressing block 11, lower horizontal shaft 12, profiling conveyor belt 13 , reel 14, second bearing housing 15, radial stripping edge roller 16, first bearing housing 17, outer plate 18, upper horizontal shaft 19 and axial stripping profiling roller 20, and the discharge port 2 is fixed on the stripping mechanism 1, the feed inlet 41 is fixed at the rear of the peeling mechanism 1, the leaf outlet 3 is opened at the bottom of the peeling mechanism 1, the upper horizontal shaft 19 is fixed on the upper part of the peel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com