Sliding-type induction material receiving device

A collection device, sliding technology, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problems of difficulty in determining the startup time of the collection device, and the zipper is not easy to remove, so as to save automatic material collection, save manpower, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

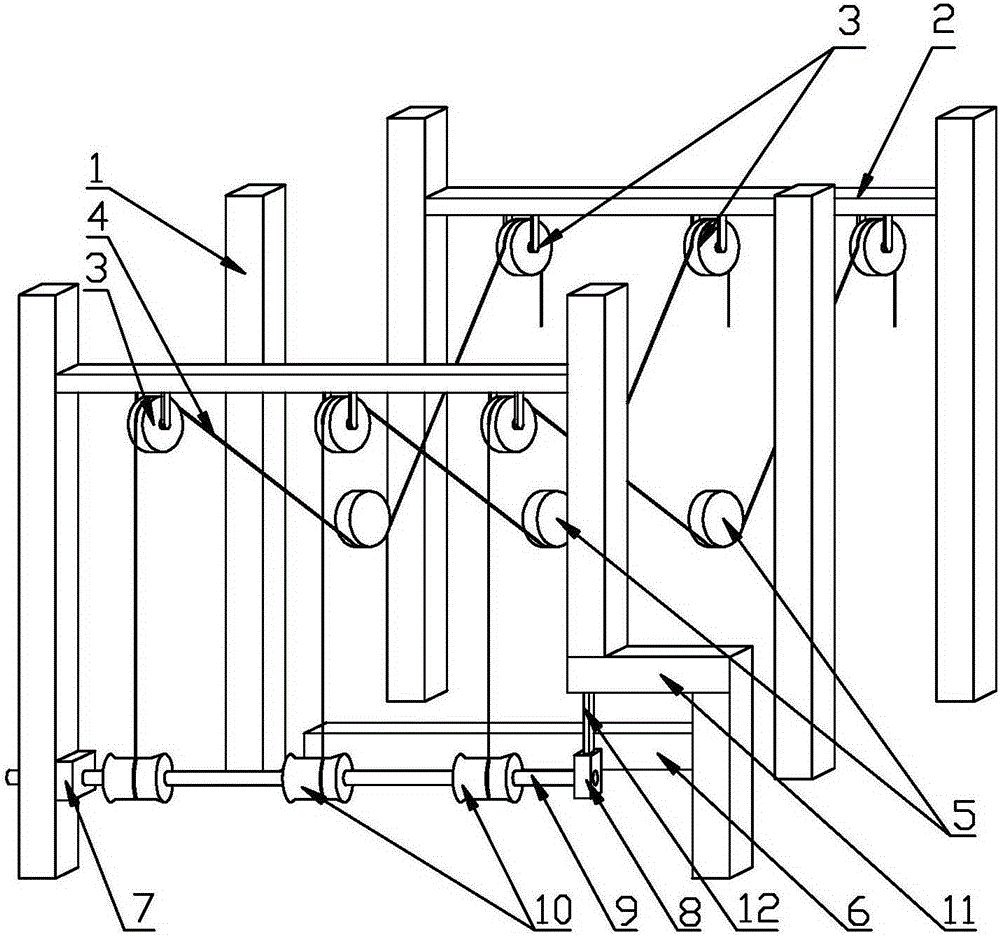

[0026] Such as figure 1 As shown, a sliding induction receiving device includes a frame 1 and an induction touch device and a zipper collection device arranged on the frame 1. The induction touch device includes two laterally fixed The fixed rods 2 on the front and rear sides, the fixed pulley 3 fixed on the bottom of each fixed rod 2 in groups, and the movable pulley 5 that moves up and down in the middle of every two fixed pulleys 3 through the zipper 4 that needs to be transmitted, the two The fixed pulley 3 and a moving pulley 5 form a receiving group, the outer circumference of the fixed pulley 3 and the moving pulley 5 have the same structure and grooves, and the grooves match the structure of the slide fastener 4 bypassing the grooves. An inductor 6 is fixedly installed in the frame 1, and the inductor 6 is located directly below the movable pulley 5;

[0027] The zipper collecting device includes a mounting seat 7 arranged on one side of the bottom of the frame 1, a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com