Ammonia process of desulfurization integral purification device and method for acid gas sulfur recovery tail gas

A technology for sulfur recovery tail gas and acid gas, which is applied in chemical instruments and methods, combustion methods, gas treatment, etc., can solve the problems of difficult to achieve high added value, low market demand for products such as sodium sulfate, and high operating costs, so as to reduce gas The effect of producing sol, realizing harmless treatment, and avoiding trailing white smoke

Pending Publication Date: 2017-05-10

ASIA PACIFIC ENVIRONMENTAL CORP

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to ensure that the tail gas is discharged up to the standard, after the conventional two-stage Claus sulfur recovery unit, super or super excellent Claus, SCOT tail gas retreatment and other processes are installed. Disadvantages such as difficulty

[0004] The sodium

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

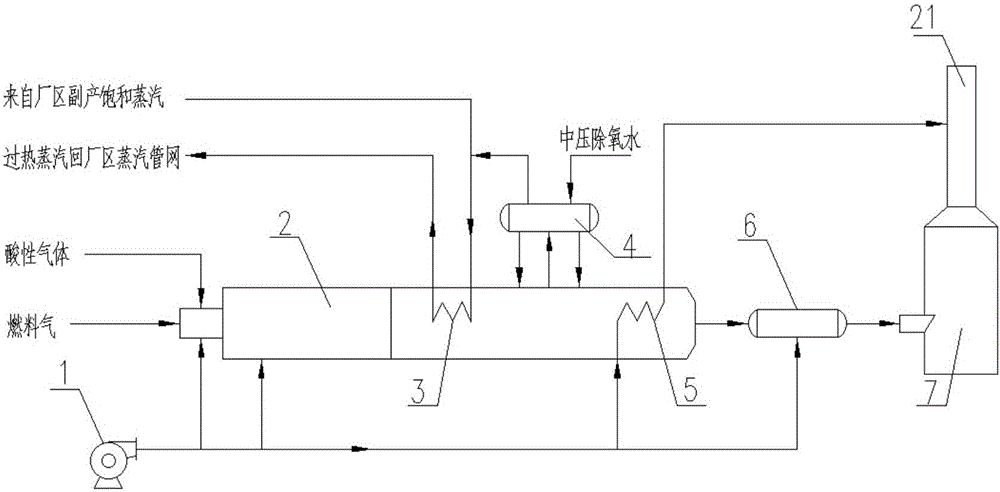

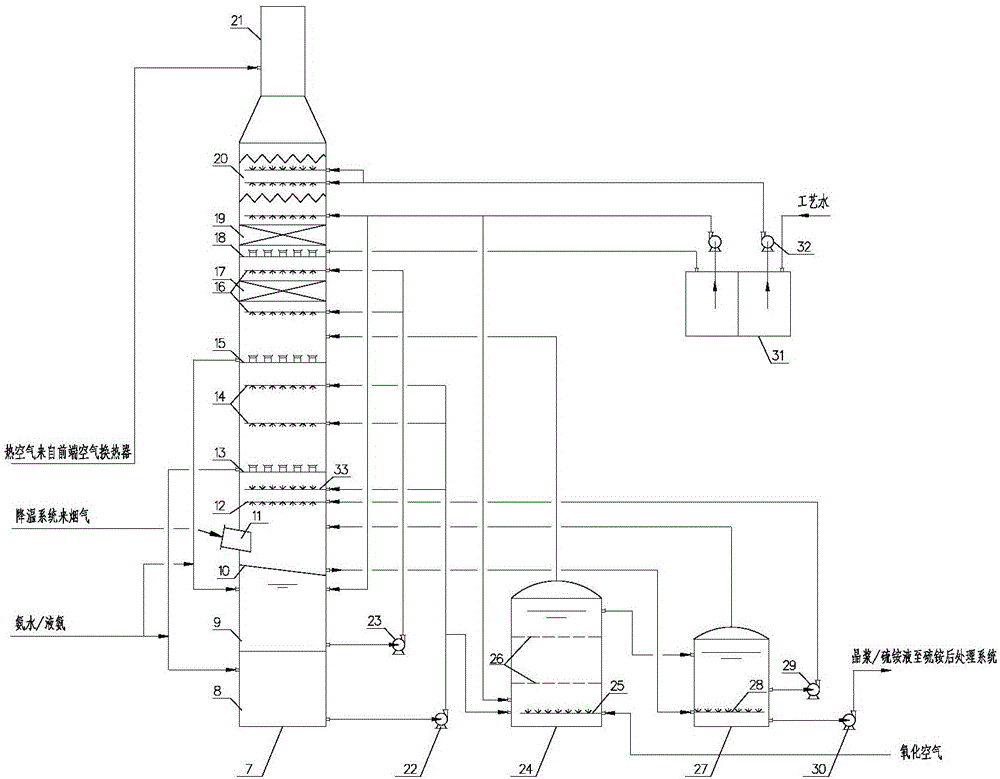

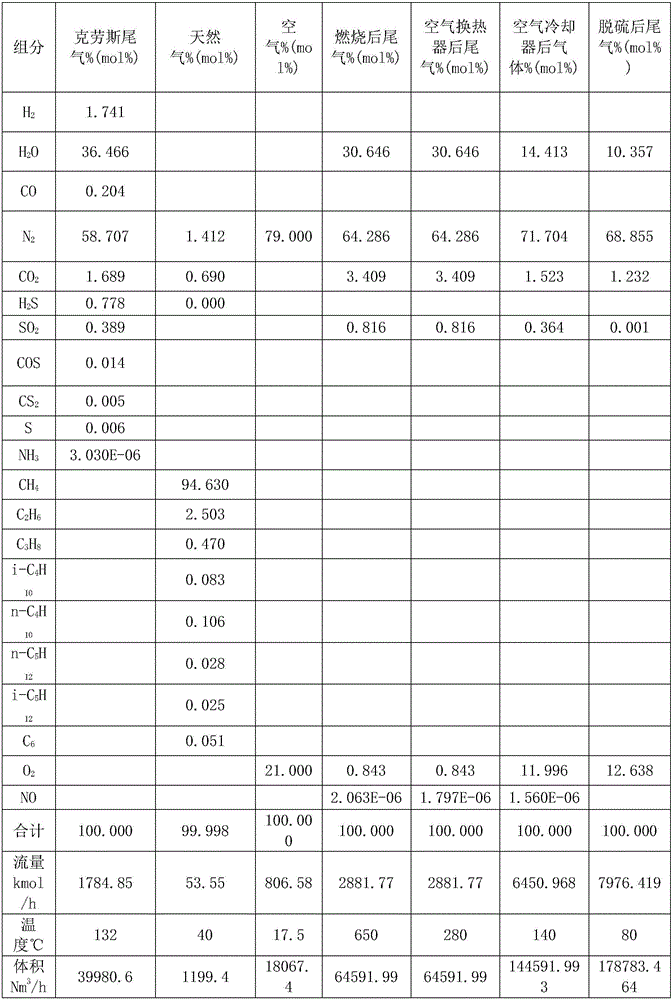

The invention discloses an ammonia process of desulfurization integral purification device for acid gas sulfur recovery tail gas. The device comprises an incinerator, a steam superheater, an afterheat recovery boiler, an air heat exchanger, an air cooler and a desulfurization device. A method for using the device for treating acid gas comprises the following steps of burning the acid tail gas under the condition of 650 DEG C to 1000 DEG C; performing secondary afterheat recovery on the burned high-temperature tail gas; performing heat recovery by the air heat exchanger; performing cooling and temperature reduction to 300 DEG C or lower; performing direct cooling and temperature reduction by the air cooler to 180 DEG C or lower; then, performing desulfurization. The device and the method have the advantages that the high absorption efficiency of high-concentration SO2 in the smoke gas can be achieved; the smoke gas is exhausted in a standard reaching way; the goals of reducing ammonia escape from the sources, blocking the ammonia escape in a process, and reducing the aerosol generation are achieved. Meanwhile, chemical fertilizer ammonium sulfate is produced; the problem of phenomenon of serious outlet smoke gas tailing white smoke of the desulfurization device is solved, so that the harmless treatment is realized.

Description

technical field [0001] The invention belongs to the technical field of environmental protection, and in particular relates to an ammonia desulfurization integrated purification device and method for acid gas sulfur recovery tail gas. Background technique [0002] Sulfur dioxide emitted from industrial processes is an important source of acid rain and smog, and acid gas is converted into a large amount of sulfur dioxide after incineration. In order to improve the environmental quality and control the emission of sulfur dioxide, desulfurization treatment is imperative. [0003] In the production process of petroleum, natural gas and coal chemical industry, a large amount of acid gas containing hydrogen sulfide will be produced. The Claus sulfur recovery process is usually used to remove hydrogen sulfide and recover sulfur. In order to ensure that the tail gas is discharged up to the standard, after the conventional two-stage Claus sulfur recovery unit, super or super excelle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/78B01D53/48F23G7/06F23J15/06F23J15/08

CPCB01D53/48B01D53/78F23G7/06F23J15/06F23J15/08B01D2251/2062B01D2258/0283Y02E20/30

Inventor 曾子平刘应隆曾波史晓杰

Owner ASIA PACIFIC ENVIRONMENTAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com