Horizontal spiral centrifugal machine

A decanter centrifuge and screw propeller technology, which is applied in the field of centrifuges, can solve the problems of difficult sediment dehydration and baffle damage, and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

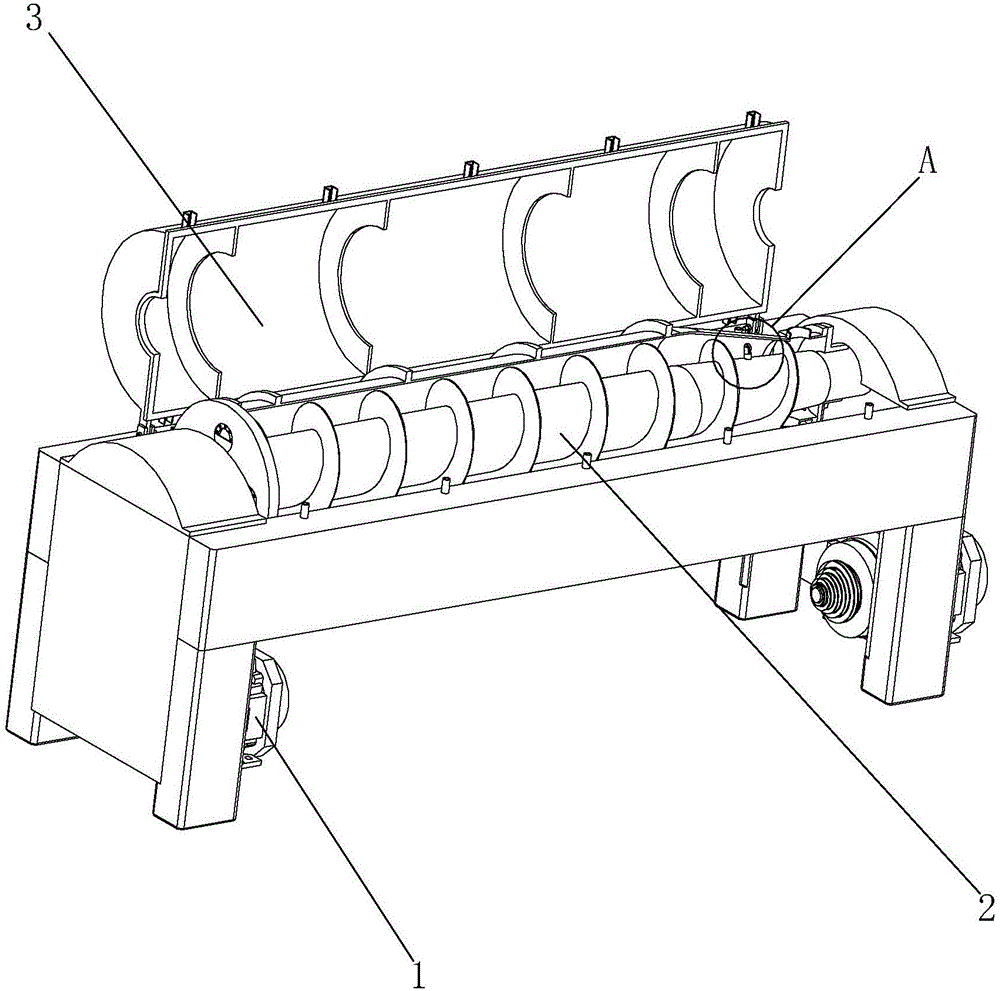

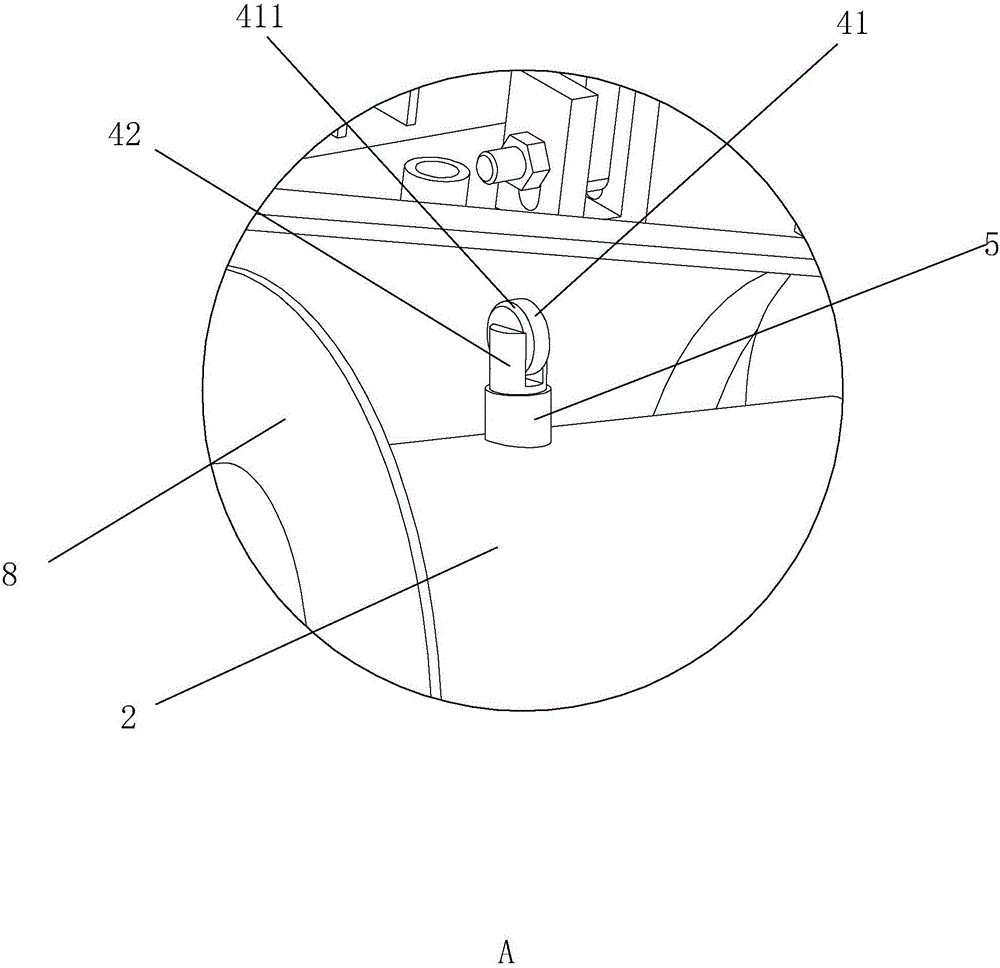

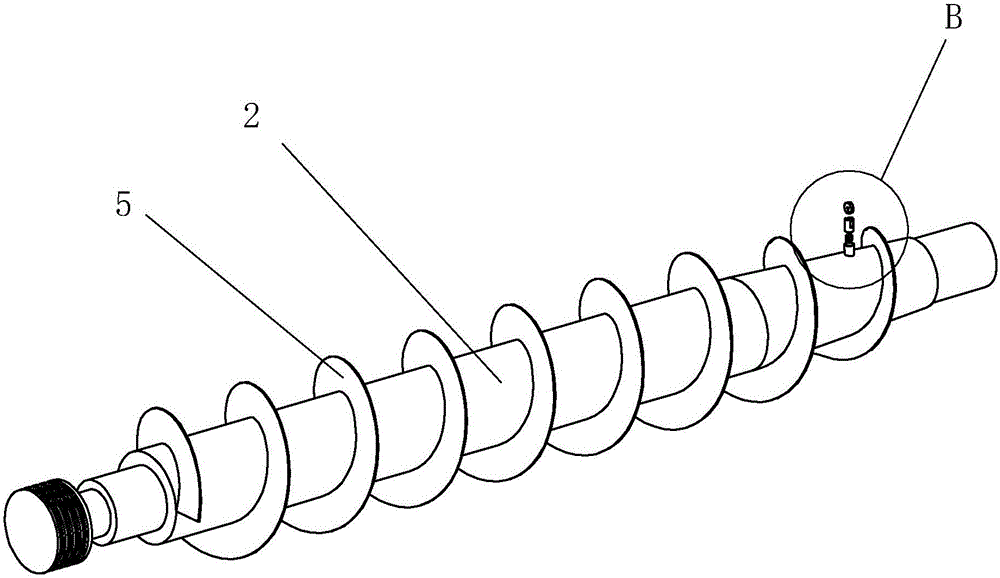

[0026] refer to Figure 1 to Figure 7 The embodiment of a decanter centrifuge of the present invention will be further described.

[0027] A decanter centrifuge, comprising a driving device 1, a drum 3, a screw propeller 2 and a casing, the driving device 1 drives the screw propeller 2 to rotate, the rotating drum 3 is arranged in the casing, and the two ends of the rotating drum 3 are respectively arranged There is a liquid phase outlet and a sediment outlet. The screw propeller 2 is arranged inside the drum 3 and a material pool is formed between the inner wall of the drum 3 and the screw propeller 2. During the working process of the decanter centrifuge, the driving device 1 will drive The screw propeller 2 works, and there will be a power device in addition, and the power device drives the rotating drum 3 to rotate. Since the screw propeller 2 is provided with blades 8, the sediment and the liquid phase are separated by the rotation of the rotating drum 3, and then Throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com