Screen tensioning device

A technology of tensioning device and screen mesh, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of complex fixed structure of screen mesh, unfavorable rapid installation and replacement of screen mesh, etc., to improve processing and maintenance efficiency, high efficiency Replacement, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

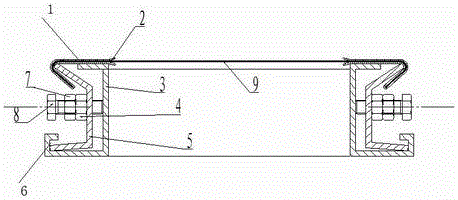

[0012] The embodiment is described in detail in conjunction with the accompanying drawings, a screen tensioning device, which includes a locking bolt 8, a hook-shaped clamping plate 1, hook plates 5 are respectively provided on both sides of the screen frame 3, and a through hole is opened on the hook plate. hole, a tension nut 4 is fixed on the outside of the through hole, and a lock bolt is provided to match the tension nut. Tighten the outer side of the nut, one end of the hook plate is inserted into the slot 6 of the screen frame, and the other end is clamped into the hook-shaped clamping plate, and the screen 9 is fixed between the two hook-shaped clamping plates, and the hook-shaped clamping plate can be used Teeth 2 are used to fix the screen, and bolts and nuts can also be used to fix the screen.

[0013] When the present invention is in use, after the screen is clamped by two hook-shaped clamping plates, the locking bolts are adjusted. Since the locked end is against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com