Device for shredding waste plastic

A technology of waste plastic and pushing device, applied in plastic recycling, mechanical material recycling, recycling technology and other directions, can solve the problems of increased viscosity, prolonged operation time, low crushing quality, etc., to achieve uniform waste plastics and improve crushing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

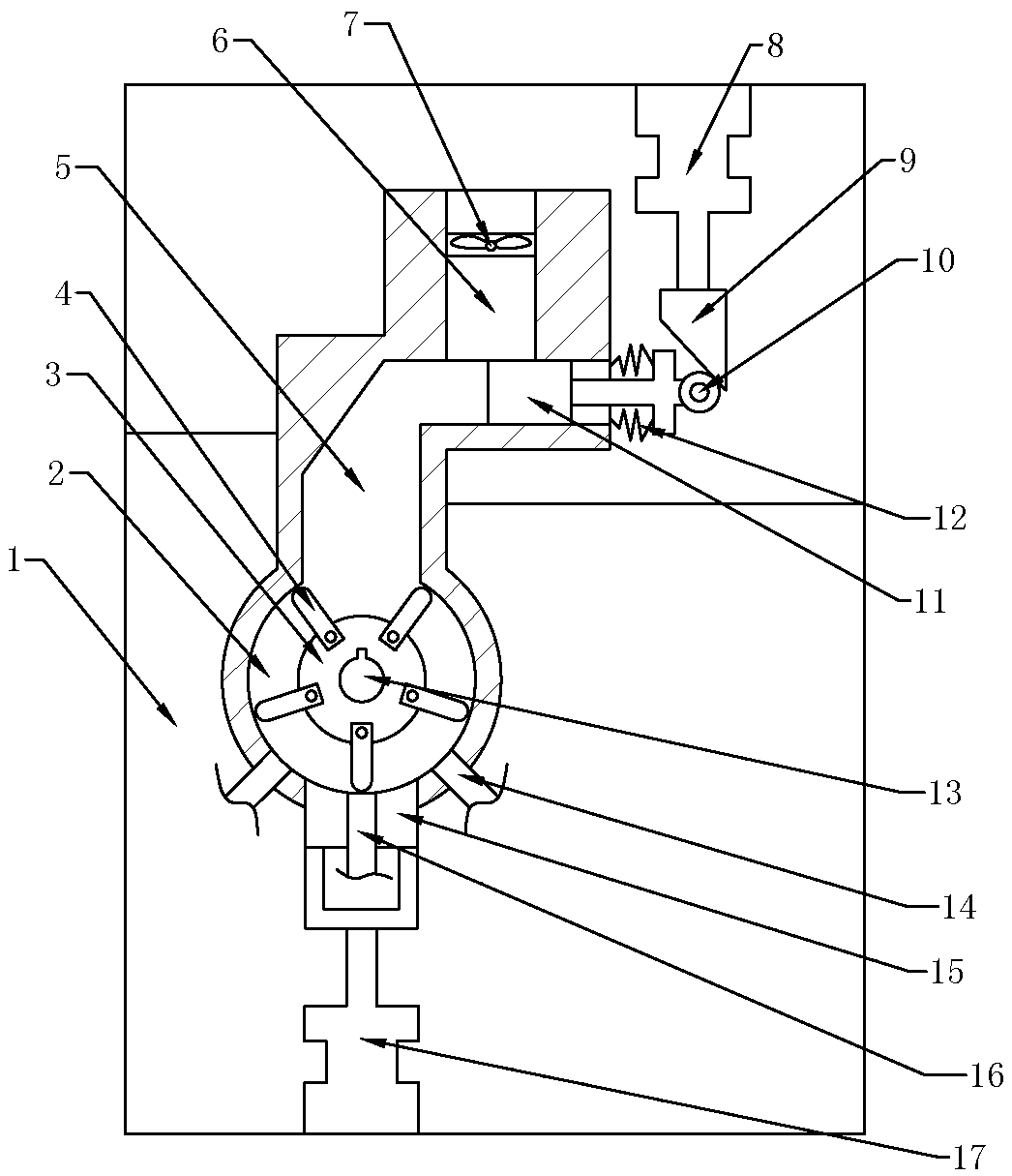

Embodiment 1

[0019] Embodiment one: if figure 1 As shown, the device for crushing waste plastics includes a frame 1. A crushing chamber 2 is fixed on the frame 1 by bolts. The crushing chamber 2 is connected with a feeding channel. The crushing chamber 2 is rotationally connected with a crushing mechanism. It includes the rotating shaft 13 connected in the crushing chamber 2, the flat key on the rotating shaft 13 is connected with the turntable 3, the breaker 4 is distributed on the circumferential direction of the turntable 3, the first motor is welded on the frame 1, and the rotating shaft 13 is driven by the first motor. There is a discharge port on the bottom of the crushing chamber 2, and a cover 15 is provided on the discharge port, and the cover 15 is slidably connected in the discharge port. The second cooler, the frame 1 is welded with a second air cylinder 17, the cover 15 is driven by the second air cylinder 17, a number of first ventilation pipes are evenly distributed on the b...

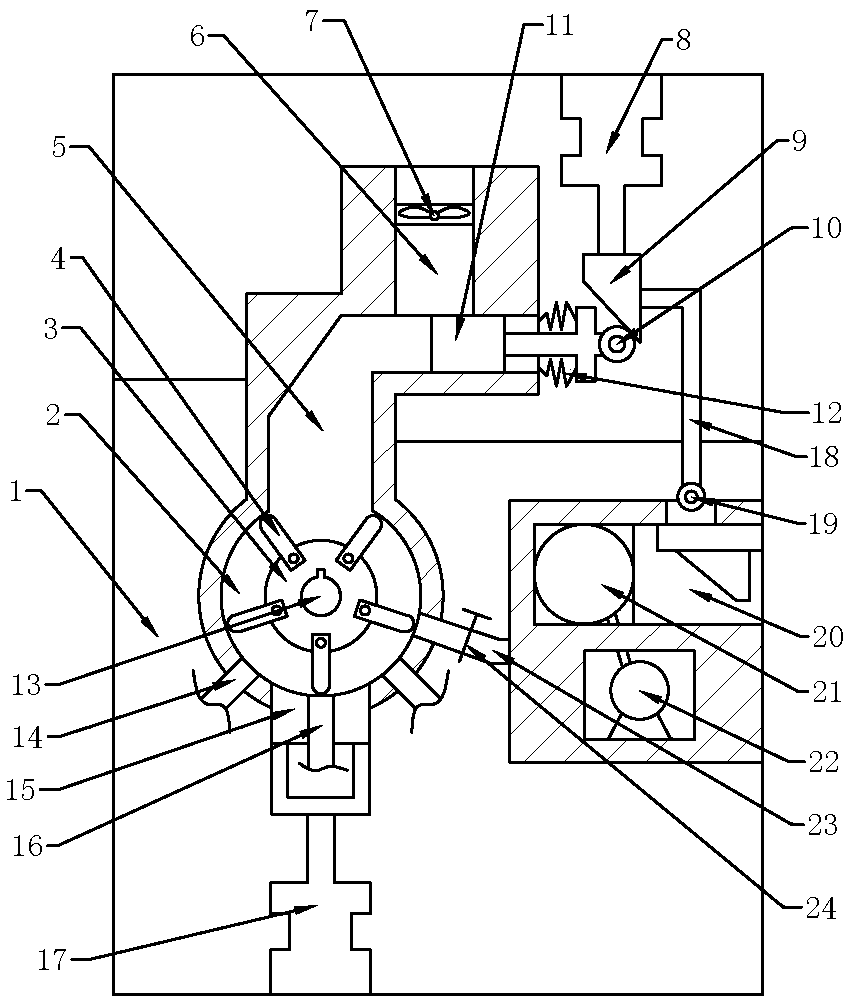

Embodiment 2

[0022] Embodiment two: if figure 2 As shown, on the basis of Embodiment 1, a cavity is opened on the frame 1 below the first roller 10, and an air bag 21 is placed in the cavity, and a third ventilation pipe 23 is communicated between the air bag 21 and the crushing chamber 2, A one-way intake valve 24 is installed on the third ventilation pipe 23, and an air pump 22 for supplying air to the air bag 21 is welded on the frame 1, and an extruding plate 20 is slidably connected to the right side in the cavity. Side has wedge groove, and wedge block 9 right sides are welded with connecting rod 18, and connecting rod 18 bottoms are equipped with a pulley 19 for offsetting against the wedge surface in the wedge groove, and pulley 19 is positioned at the top of the wedge groove.

[0023] During the specific operation, when using the first cylinder 8 to reciprocate the wedge 9, start the air pump 22 to replenish air to the air bag 21. After the push block 11 pushes the material sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com