Plastic injection mold capable of cutting off remnants in mold

A technology of plastic injection molding and in-mold, applied in the field of plastic injection molds, can solve the problems of product quality impact and labor consumption, and achieve the effects of stable product quality, prolonging service life and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

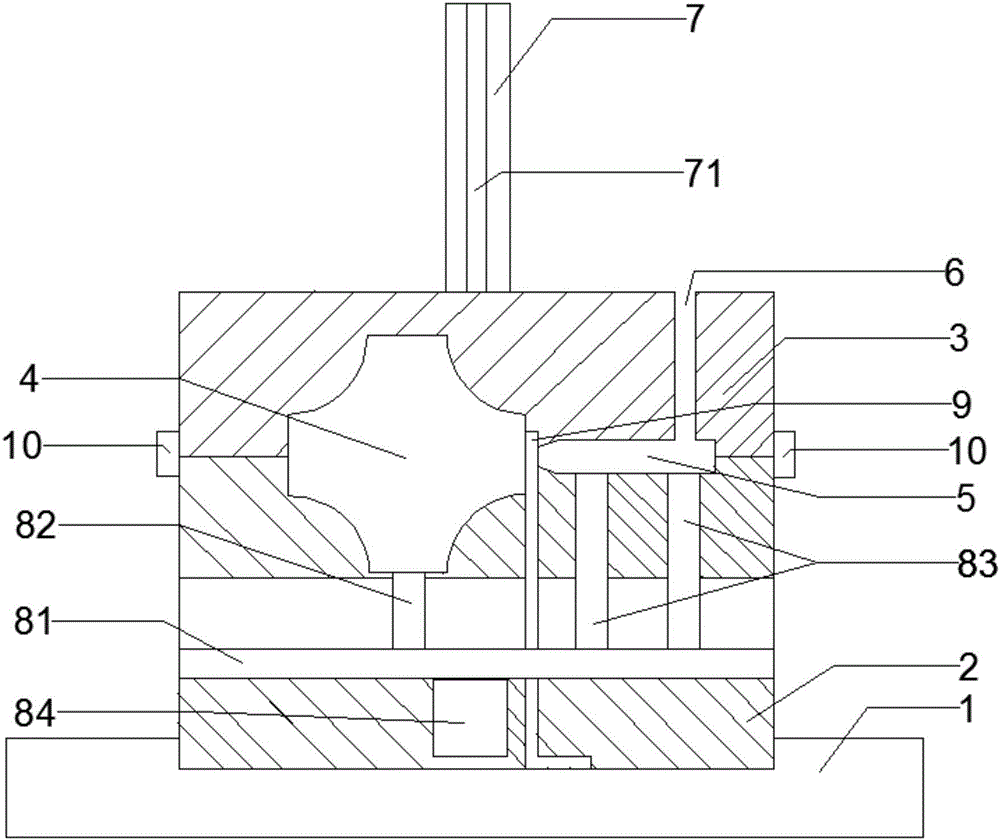

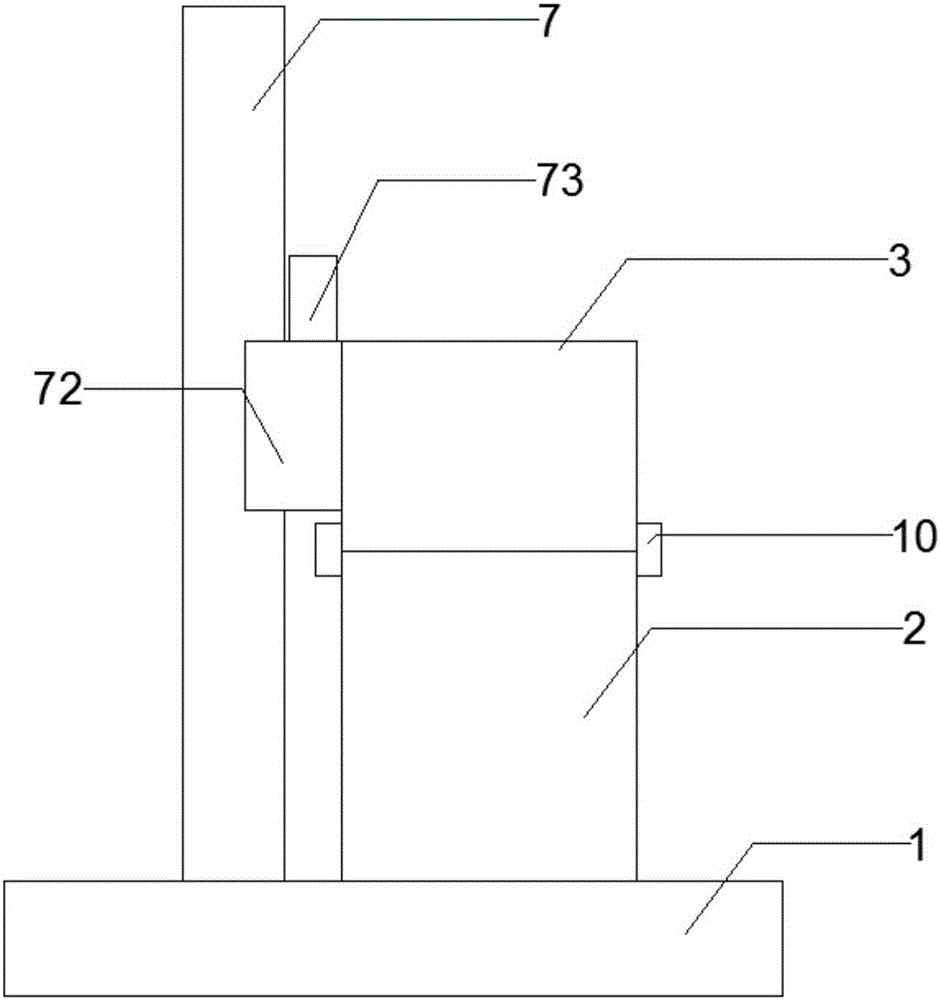

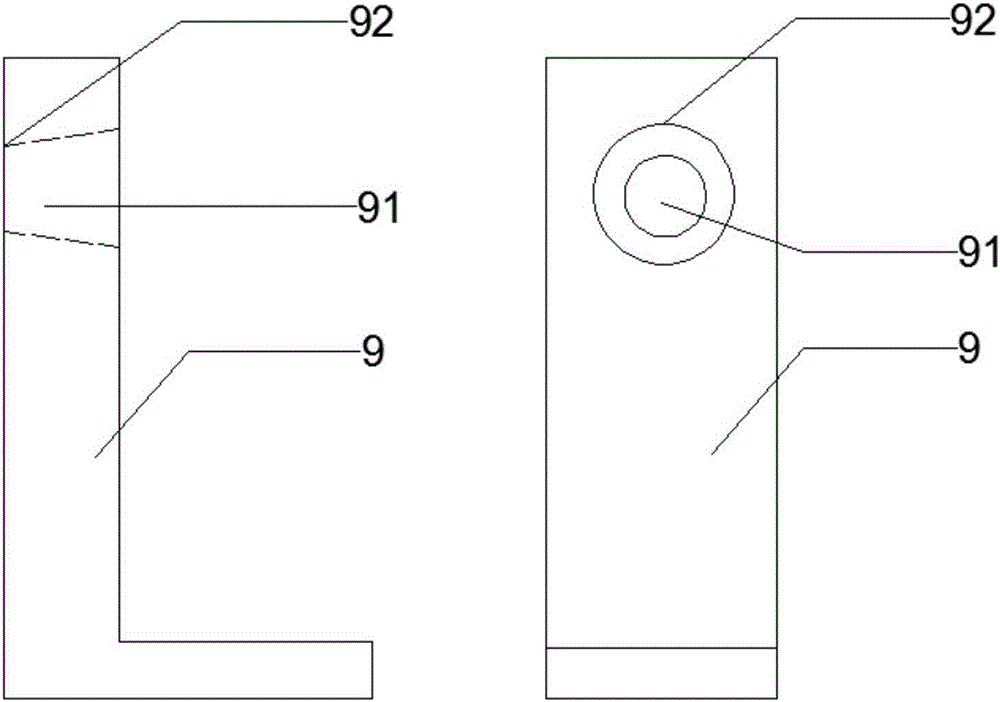

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a plastic injection mold that can be cut off from the mold, including a female mold core 3, a male mold core 4, a male mold insert 9 and an ejection mechanism 8; the male mold core 2 is installed On the upper end surface of the installation base 1, a column 7 with a linear slide rail 71 is fixedly connected to the upper end surface of the installation base 1, and a positioning slider 72 suitable for the linear slide rail 71 is installed on the column 7. The second drive cylinder 73 used to drive the positioning slider 72 to slide up and down along the column 7, the female mold core 3 is fixed on the positioning slider 72 and is located directly above the male mold core 2, the male mold core 2 and the female mold core When the core 3 is closed, the injection mold cavity 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com