Anti-explosion oil tank

A fuel tank and oil pump technology, which is applied in the field of explosion-proof fuel tanks, can solve the problems that rescuers and wounded cannot escape in time, sparks are easy to cause explosions, and car rollovers occur, and achieve the effects of convenient production, low cost, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

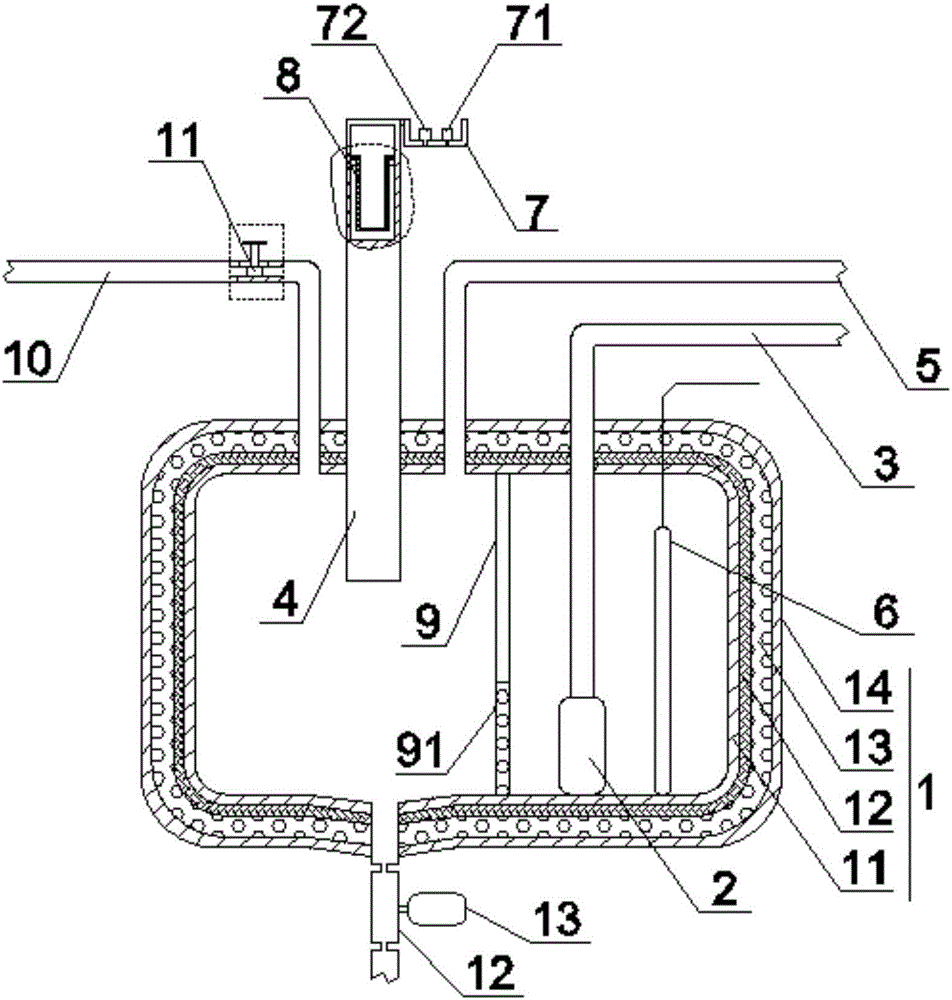

[0019] as follows figure 1 As shown, the explosion-proof oil tank includes a casing 1, an oil pump 2, an oil pipe 3, an oil inlet pipe 4, an oil return pipe 5, and a liquid level sensor 6; the oil pump 2 is installed in the oil tank; one end of the oil pipe 3 passes through the shell 1 and The oil outlet of the oil pump 2 is connected, and the outer surface of the upper oil pipe 3 is seamlessly fixed with the casing 1; one end of the oil inlet pipe 4 is seamlessly connected with the inside of the casing 1; one end of the oil return pipe 5 is seamlessly connected with the inside of the casing 1; The liquid level sensor 6 is installed in the housing 1 and is electrically connected with the vehicle control device;

[0020] The shell 1 includes an inner steel plate layer 11, a rock wool layer 12, a honeycomb aluminum plate layer 13, and an outer steel plate layer 14; Oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com