Omni-directional differential drive wheel device and AGV

A differential drive and drive device technology, applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems of high cost, increased control difficulty, low load, etc., and achieve low cost, convenient steering control, and driving deviation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

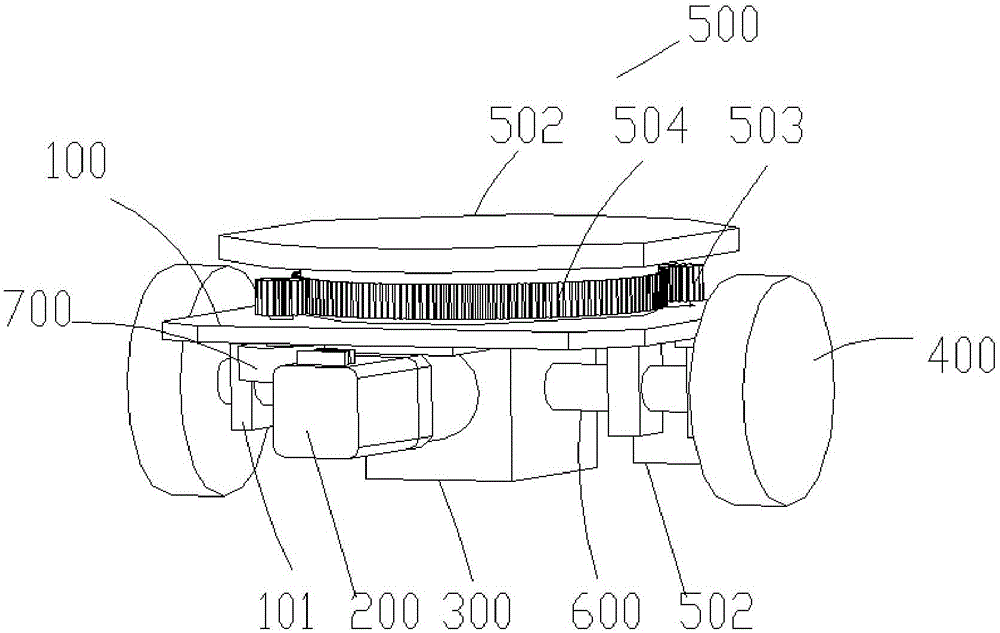

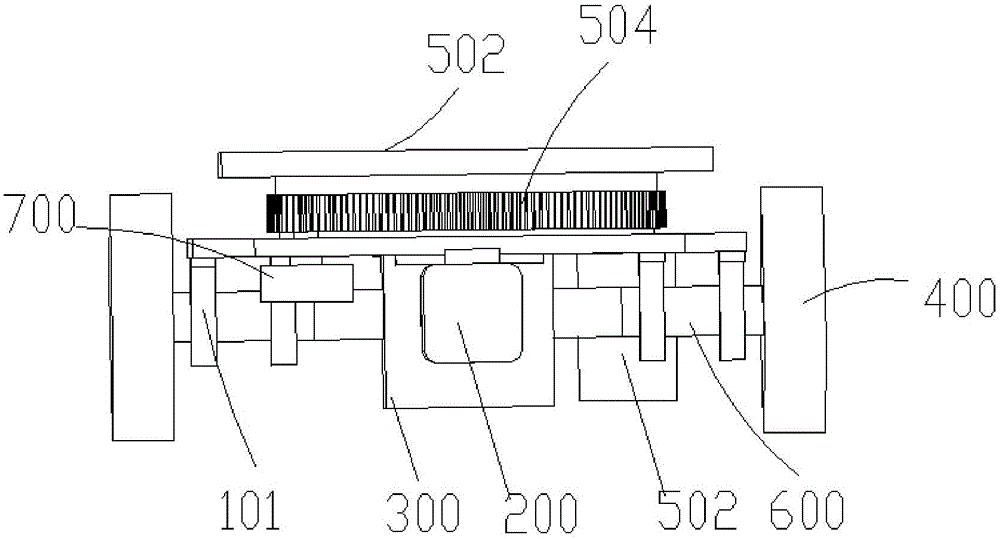

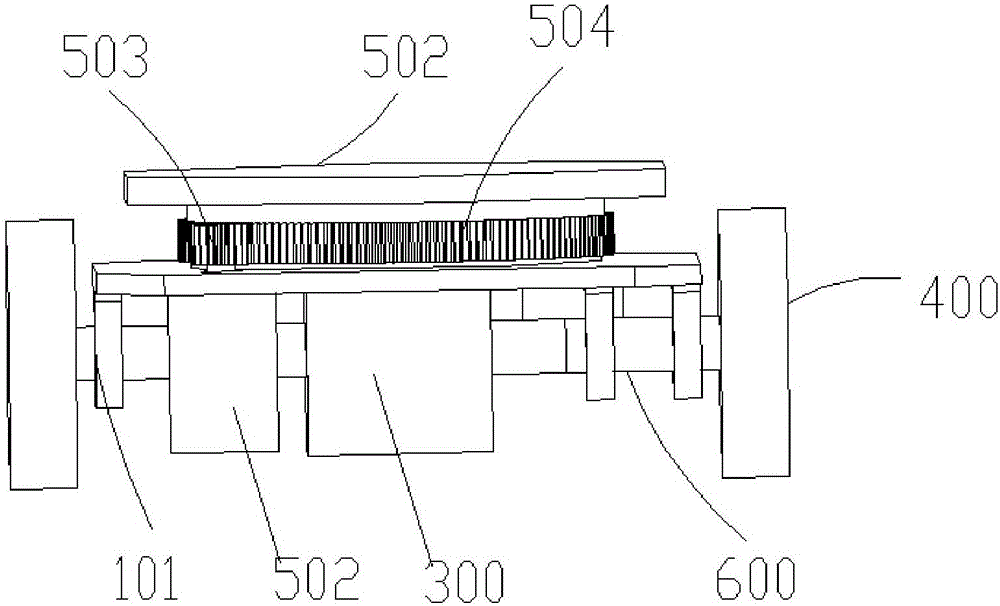

[0047] See figure 1 ; The present embodiment provides an omnidirectional differential drive wheel device, which can travel in any direction, and utilizes one driving device 200 to simultaneously drive two wheels 400, compared with the prior art that utilizes two motors to drive a wheel train In terms of structural form, the control of this device is more convenient than the separate driving of two motors; and the speed of the two wheels 400 is automatically distributed by the differential 300, and the steering is more stable and the steering control is more convenient.

[0048] The specific structure of the omnidirectional differential drive wheel device provided by the present invention is illustrated below:

[0049] Please refer to Figure 1 to Figure 4 shown;

[0050] The device includes: a fixed base 100 , a driving device 200 , a differential 300 , wheels 400 and a steering device 500 .

[0051] The driving device 200 is in transmission connection with the differential...

Embodiment 2

[0084] Please refer to Figure 4 , The purpose of this embodiment is to provide an AGV trolley, including the omnidirectional differential drive wheel device as described above.

[0085] During specific setting, a plurality of above-mentioned omnidirectional differential drive wheel devices can be set at the bottom of the AGV trolley.

[0086] The AGV trolley using the above-mentioned omnidirectional differential drive wheel device has the following advantages:

[0087] 1. Through the joint drive of the drive device, differential gear and steering device, the AGV trolley can be turned freely in 360 degrees, and at the same time, it can realize the in-situ steering with zero turning radius.

[0088] 2. Each wheel train has two wheels landing on the ground at the same time, which improves the carrying capacity of the AGV trolley;

[0089] 3. The steering motor precisely controls the direction of the wheels, and the AGV trolley has small driving deviation;

[0090] 4. One moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com