Edge fixing structure of yacht trailer

A technology for fixing structures and trailers, which is applied in the direction of motor vehicles, goods transport vehicles, and vehicles for freight transportation, etc., can solve the problems of low strength of the fixed structure at the edge, easy to break, etc., and achieve stable connection, firm structure, and structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

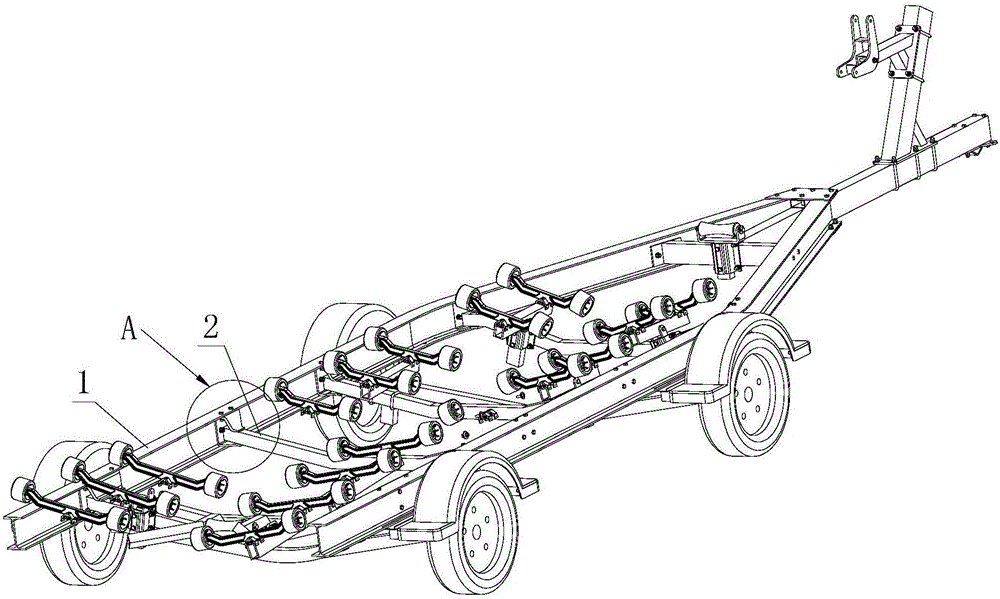

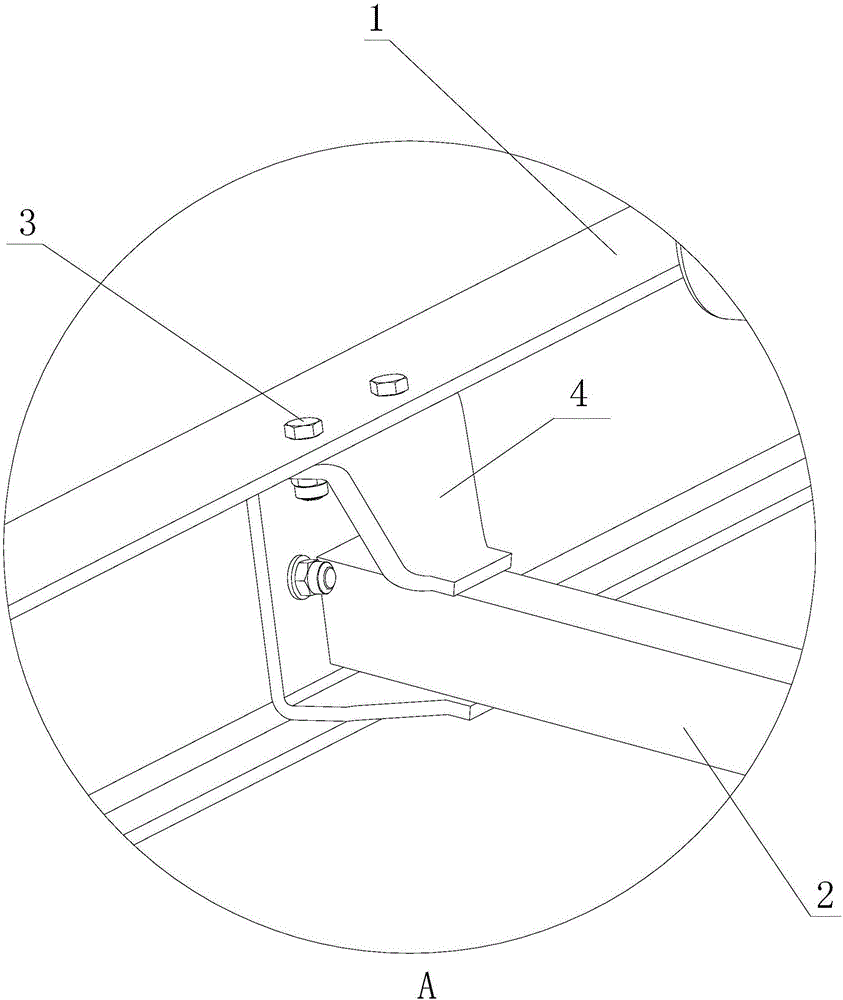

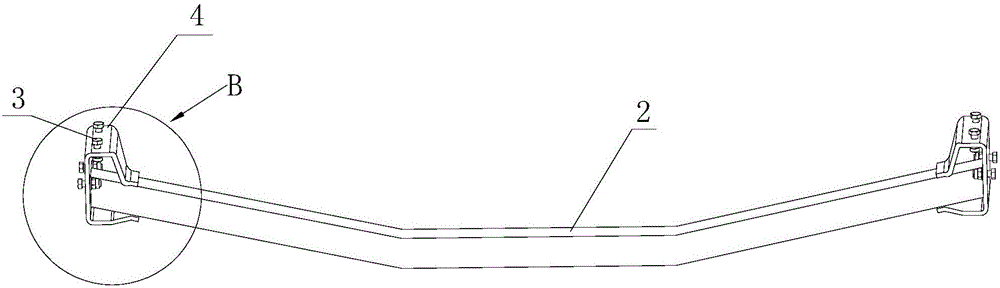

[0034] like Figure 1~5 As shown, this embodiment provides a side fixing structure of a yacht trailer, including side frames 1 on both sides of the support frame and support rods 2 for supporting the wheel frame, and also includes side frames 1 and support rods for fixed connection The fixing seat 4 of the rod 2 and the fastener 3 for fastening the fixing seat 4 and the side frame 1; the support rod 2 adopts a square aluminum tube.

[0035] like Figure 5 As shown, the side frame is made of I-shaped aluminum profile, and the side frame made of I-shaped aluminum profile has a “[”-shaped slot, which can be matched with the fixing seat. The fixing seat 4 is in the shape of “[”, and the fixed The seat 4 is embedded in the slot of the side frame 1 .

[0036] The use of I-shaped aluminum can not only achieve the effect of fixing the support rod 2; it can also save preparation materials, which are basically available in the market, and can also reduce the weight of the trailer, mak...

Embodiment 2

[0049] On the basis of embodiment 1, this embodiment is further elaborated:

[0050] Compared with Embodiment 1, the support rods 2 of this embodiment are all square aluminum tubes. The difference is that: the support rods 2 in this embodiment are also provided with vertical stiffeners 120; when the yacht is on the trailer, the support The load-bearing part of the rod 2 is in its vertical direction, therefore, the vertical reinforcing rib 120 can make the structural strength of the support rod higher and the load-bearing strength stronger.

[0051] The vertical reinforcing rib 120 divides the inside of the support rod 2 into two compartments 121 separated from each other; wherein, the traditional boat trailer is usually made of galvanized iron, and because of its heavy weight, it is inconvenient to transport and the freight is relatively expensive. , and the boat trailer of the present invention, its support frame and side frame are all made of aluminum material, and the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com