Edge sealing structure and method for fairing water leakage hole

A technology for water leakage holes and fairings, applied in the field of fairings, can solve problems such as the inability to completely limit water immersion into the cloth, the water-retaining cloth being easy to fall off, and the corroded materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

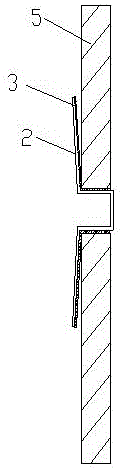

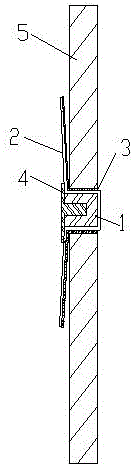

[0033] This embodiment discloses a method for edge sealing a water leakage hole of a fairing, which includes a guide rod 1 and a water retaining cloth 2; including the following steps:

[0034] (1) Cover the side of the water retaining cloth 2 coated with the adhesive 3 on the outside of the leak hole; in order to prevent the adhesive 3 from blocking the leak hole and causing accumulated water to not flow out of the leak hole smoothly, apply the adhesive 3 , reserve a non-adhesive-coated area on the water retaining cloth 2, and this area stretches into the deepest part of the water leakage hole. In addition, the present invention can also first coat the adhesive agent on the inner wall of the water leakage hole and the outer periphery of the water leakage hole, and then cover the outside of the water leakage hole with the water retaining cloth. Since there are gaps in the water retaining cloth, in order to further ensure that the accumulated water can flow out of the non-adhes...

Embodiment 2

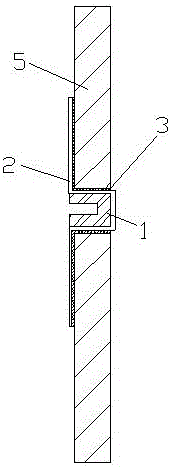

[0045] This embodiment discloses an edge-sealing structure for a water leakage hole of a fairing, which includes a water leakage hole opened on the fairing, and the outside of the water leakage hole is covered with a water-retaining cloth; the water-retaining cloth is glued to the water leakage hole evenly on the outer perimeter and on the inner wall.

Embodiment 3

[0047] This embodiment discloses an edge-sealing structure for a water leakage hole of a fairing, which includes a water leakage hole opened on the fairing, and the outer side of the water leakage hole is covered with a glass fiber woven cloth; the glass fiber woven cloth is smoothed by epoxy resin glue Glue it on the periphery and the inner wall of the outside of the leakage hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com