Combined barrel hoop conversion device

A conversion device and combined technology, applied in the field of machinery, can solve the problems of not being able to hold small-diameter drums, etc., and achieve the effects of improving equipment utilization, multiple benefits, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

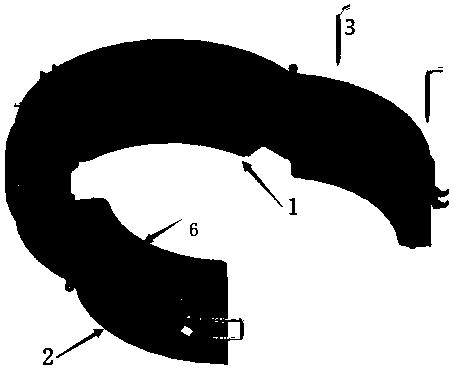

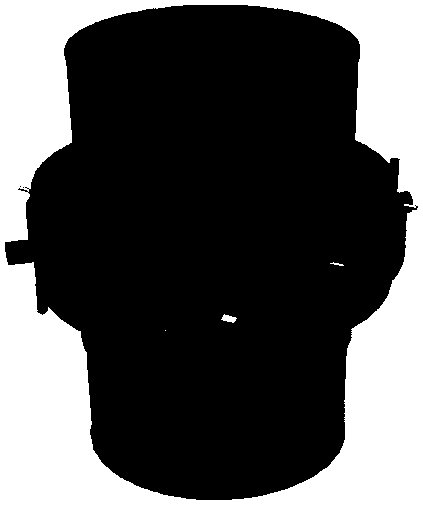

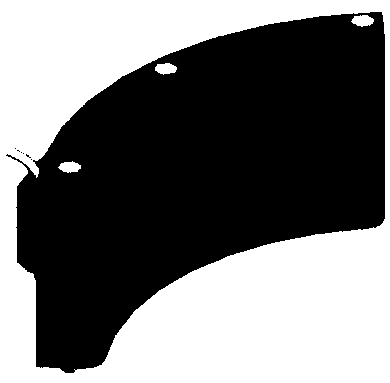

[0029] Such as figure 1 , figure 2 As shown, the combined drum hoop conversion device mainly includes a lining tile module 1, and the combined drum hoop conversion device also includes a standard drum hoop 2 and a pin 3; the four lining tile modules 1 are arranged on the standard drum hoop 2 Around the inner side, and a part of the lining tile module 1 is a square hole that passes through the standard bucket hoop 2, and the standard bucket hoop 2 and the lining tile module 1 are connected together with a pin 3, and the pin 3 is arranged in the standard Bucket hoop 2 outside. The lining tile module 1 includes a first lining tile 4, a second lining tile 5, and a hexagonal bolt 6. The upper and lower three pieces of the first lining tile 4 are in contact with the middle four pieces of the second lining tile 5, and are connected with the hexagonal bolts 6. fasten. The first lining tile 4 includes an arc-shaped body, and the body is provided with three through holes in the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com