Combined barrel hoop transforming device

A conversion device and combined technology, which is applied in the field of machinery, can solve the problems of small-diameter drums that cannot be hooped, and achieve the effects of protecting appearance quality, saving costs, and improving equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

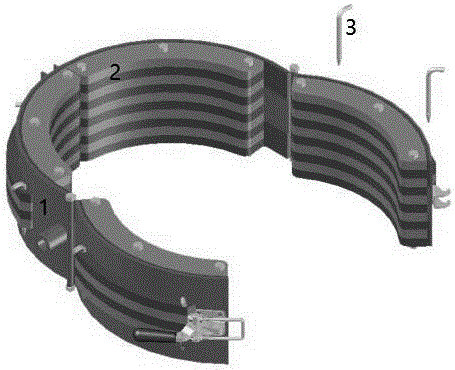

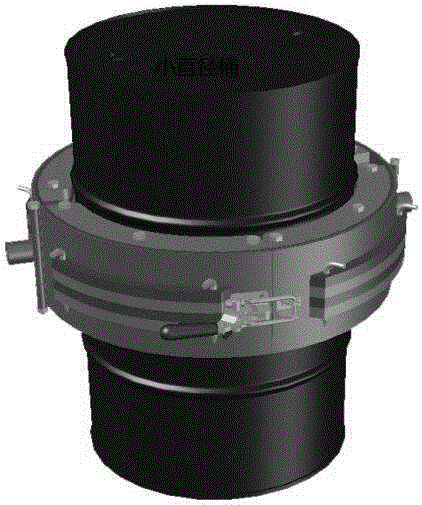

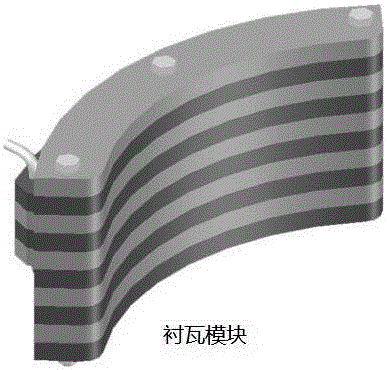

[0025] As shown in Figure 1 and Figure 2, the combined drum hoop conversion device mainly includes a standard drum hoop 1, lining tile module 2, pin 3, bolts and nuts; the lining tile module is used by lining tile A and lining tile B Bolts and nuts are connected as one, and pins are used to connect with standard barrel hoops.

[0026] Specific installation method:

[0027] 1. First use bolts and nuts to assemble the lining tile A and lining tile B into a lining tile module (as shown in Figure 3 and Figure 4); 2. Place the standard barrel hoop on the installation platform, and remove the parts completed in step 1 from the hoop Insert the inner side into the square hole of the hoop, and then insert the pin (as shown in Figure 7); 3. Repeat steps 1 and 2 to install the other 3 places in turn (as shown in Figure 8, Figure 9, and Figure 1).

[0028] Based on the above, the present invention achieves the expected purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com