Seeding rotation power transmission and cut-off converter of traction type seeder

A technology of rotary power and seeder, applied in the direction of seeder parts, mechanical drive clutches, clutches, etc., can solve the problems of large size, laborious and laborious dismantling of chains, and difficulty in assembling tools, etc., to achieve small size and applicable Wide-ranging, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

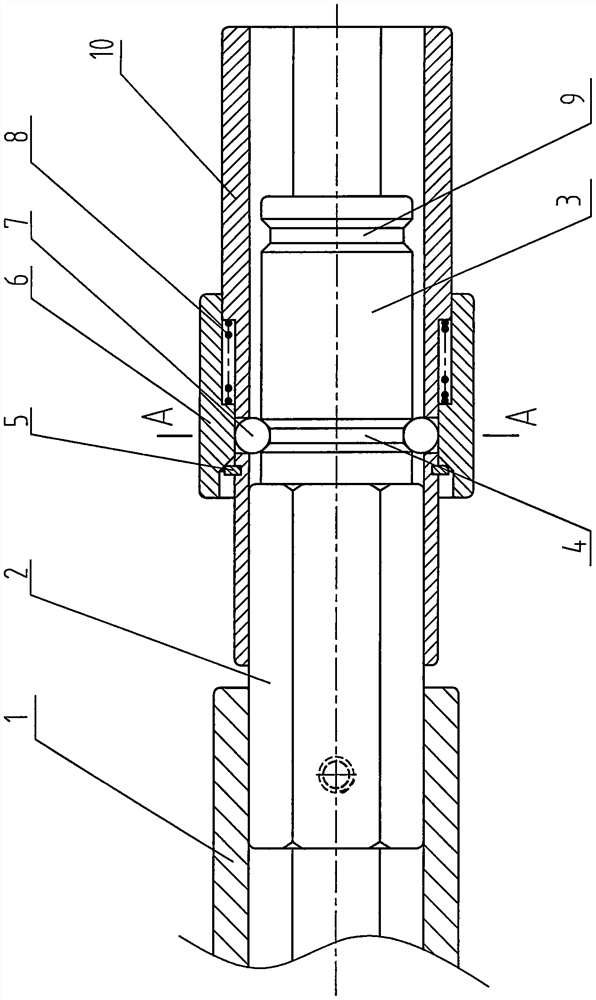

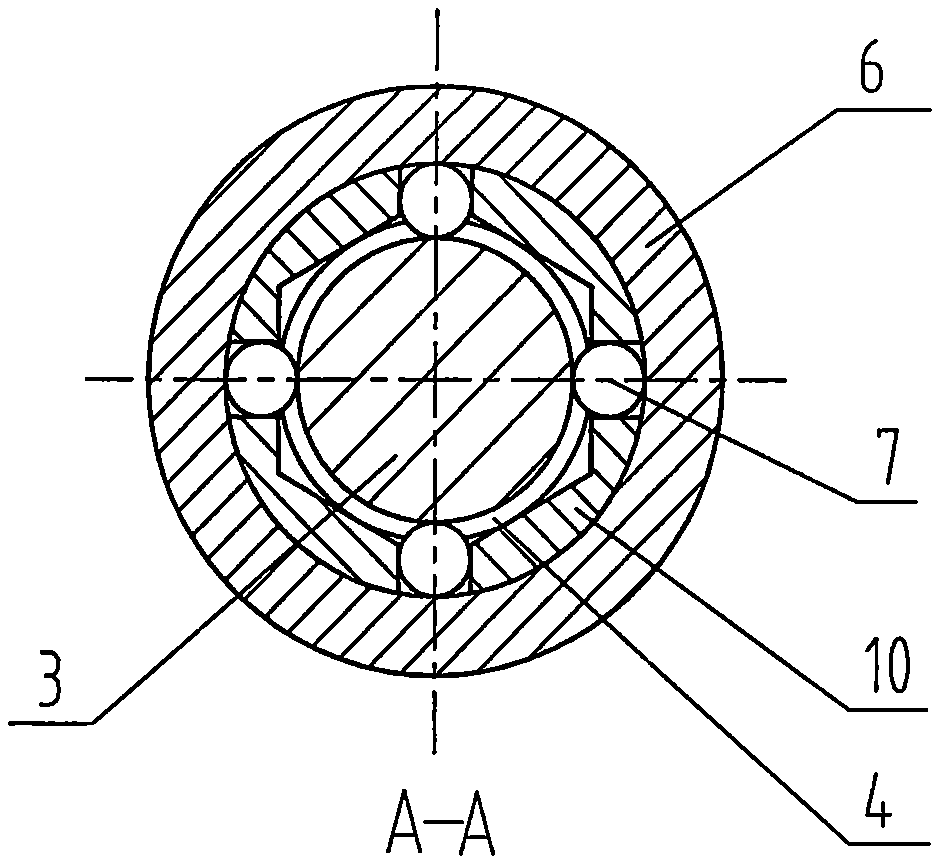

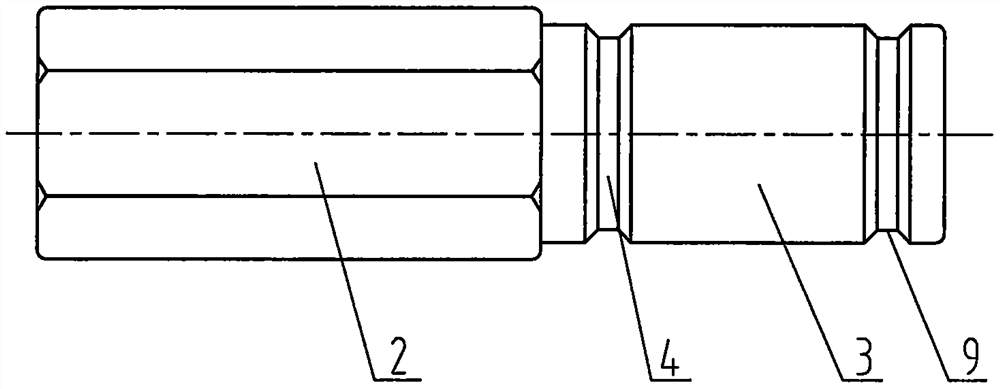

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A traction seeder sowing rotation power transmission and cutting converter, the hexagonal shaft 2 is fixed on the right side of the inner hexagonal sleeve 1 of the power input, and the cylindrical shaft 3 and the hexagonal shaft 2 are fixed on the hexagonal shaft 2 On the right end face, a power transmission locking groove 4 and a power cutting locking groove 9 are sequentially arranged on the circular outer surface of the cylindrical shaft 3 from left to right, and the left side of the outer shoulder-shaped power output inner hexagonal tube shaft 10 The side part is axially movably sleeved on the outside of the hexagonal shaft 2 and the cylindrical shaft 3. The outer shoulder-shaped power output inner hexagonal tube shaft 10 and the hexagonal shaft 2 are radially and circumferentially locked, and the outer shoulder-shaped The power output inner hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com